A process for improving the fatigue life of automobile half shaft

An automobile half shaft and process method technology, which is applied in the directions of axles, wheels, vehicle parts, etc., can solve the problems of stress concentration at the spline, and achieve the effect of overcoming the stress concentration, enhancing the strength, and reducing the cost of after-sales three guarantees.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

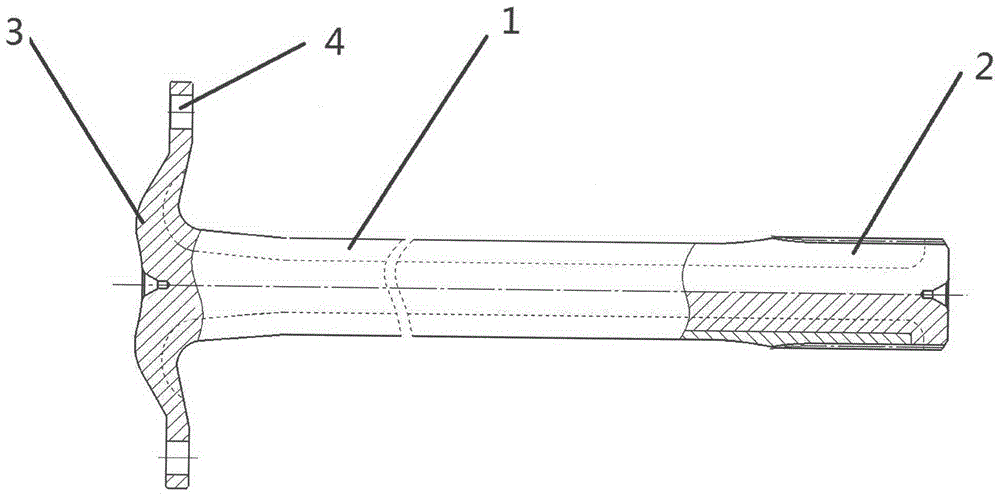

[0020] A kind of processing method of the present invention improves the fatigue life of automobile axle shaft, and the steps are as follows:

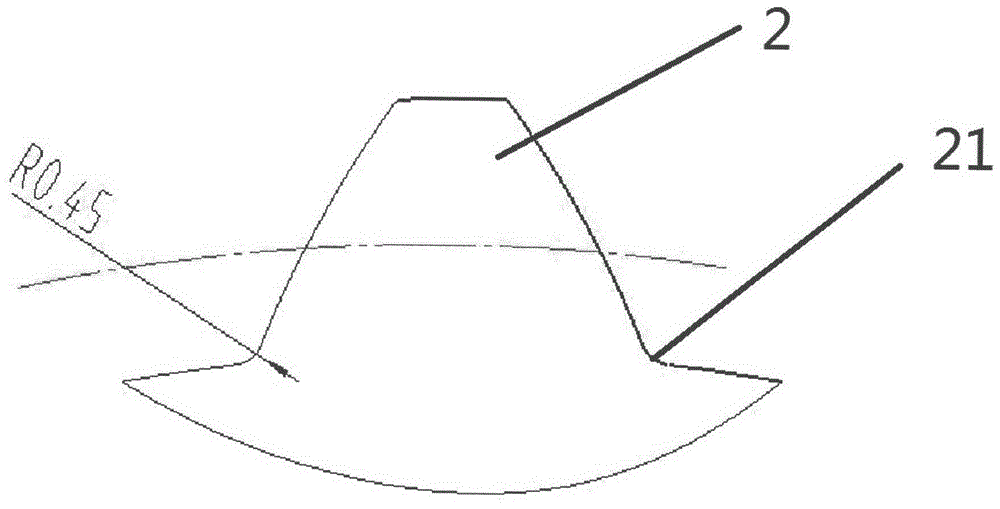

[0021] Firstly, the bar stock is forged to form an automobile semi-shaft blank. Then the semi-shaft blank of the automobile is subjected to quenching and tempering treatment, and the quenching and tempering hardness is HB229-269. The specific modulation process parameters are: quenching temperature is 840-860°C, quenching medium is oil cooling; tempering temperature is 600-640°C, tempering and heat preservation The time is 1 hour, and the cooling medium is air. Taking the central holes at both ends of the modulated automobile half-shaft blank as a positioning reference, the outer circle is turned according to the size requirements to obtain the automobile half-shaft. Carry out spline 2 milling on the half shaft of the car, the fillet of the spline tooth root 21 is R0.25mm, and increase the fillet of the spline tooth root 21 by grindin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com