Bamboo removal equipment for bamboo tubes

A technology for removing green bamboo and bamboo tubes, applied in metal processing equipment, used abrasive processing devices, manufacturing tools, etc., can solve irregular shape, only 60%~70%, uneven cutting force, etc. problems, to achieve the effect of improving material utilization, saving manufacturing costs, and uniform bamboo tube surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the principle and structure of the present invention, preferred embodiments of the present invention will now be described in detail with reference to the accompanying drawings.

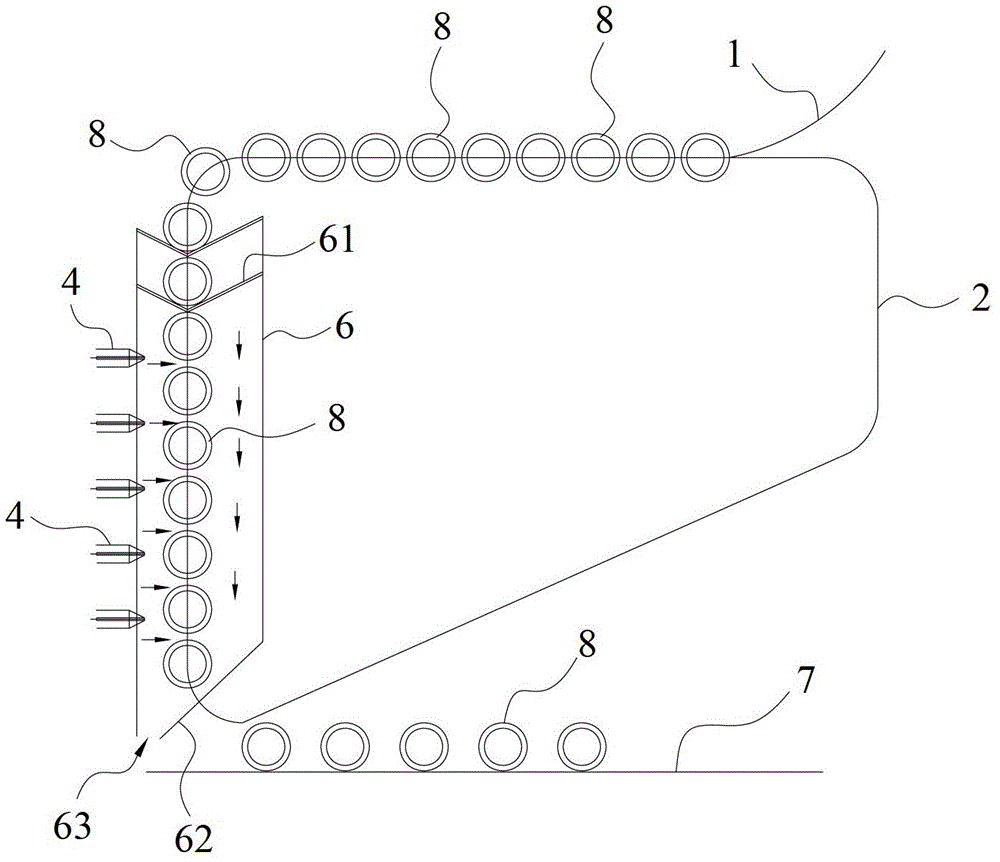

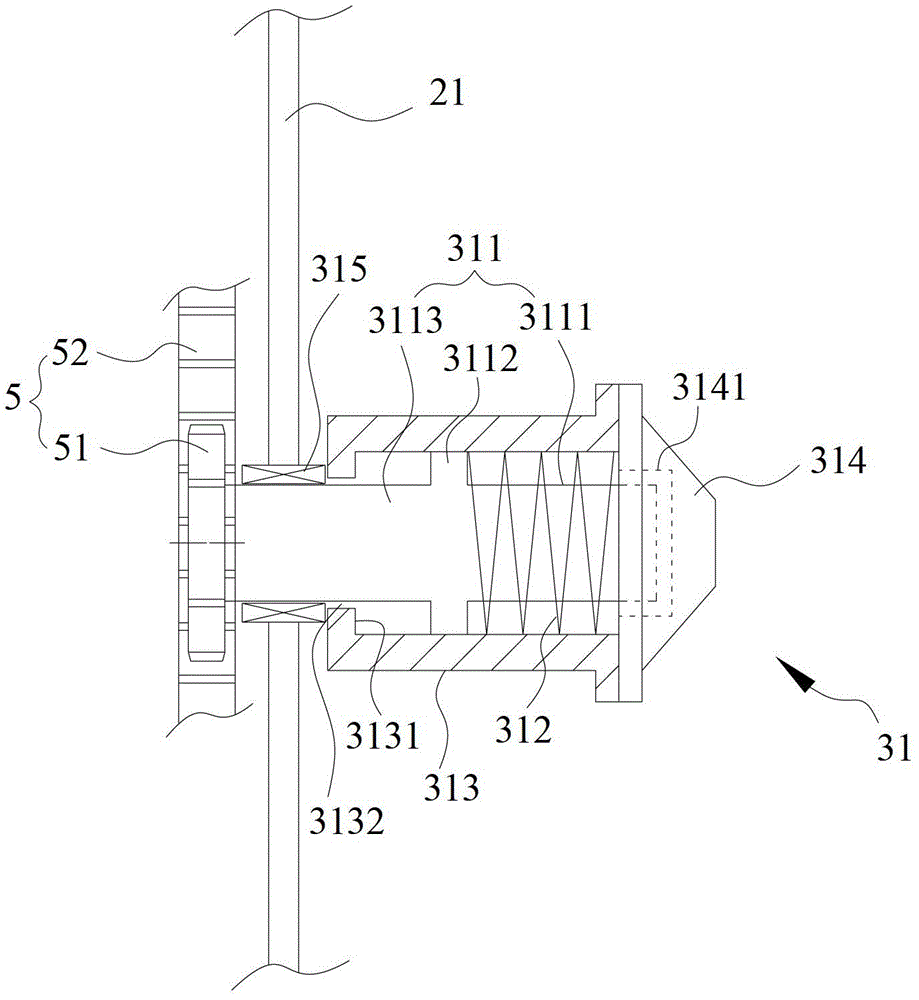

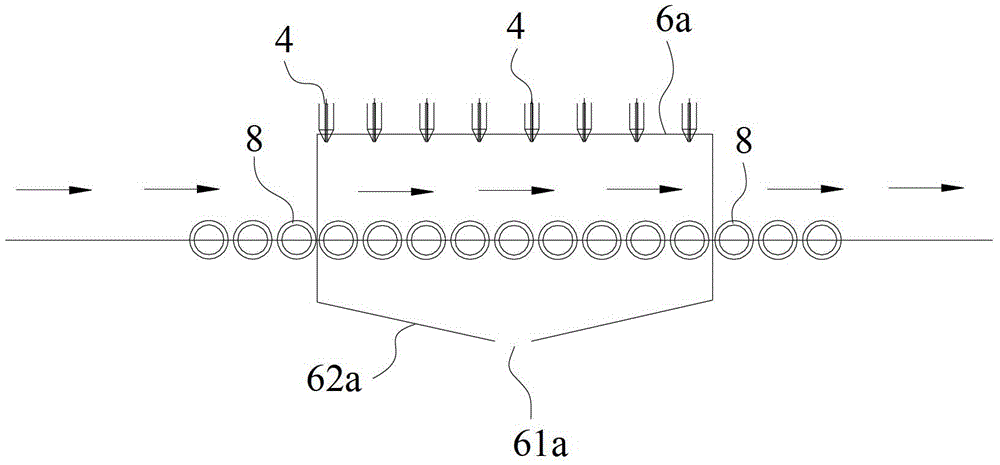

[0027] refer to figure 1 and figure 2 , The green bamboo removal equipment of the bamboo tube of the present invention comprises: a feeding mechanism 1, a bamboo tube conveying mechanism 2, a bamboo tube clamping mechanism 3, a high-speed particle nozzle 4, a bamboo tube rotating mechanism 5, a sand chamber 6 and a discharge mechanism 7.

[0028] The feeding mechanism 1 is connected with the bamboo tube conveying mechanism 2, and is used for automatically transporting the bamboo tube 8 to the bamboo tube conveying mechanism 2. During specific implementation, the feeding mechanism 1 may be a roller conveyor or a belt conveyor commonly used in the prior art. Of course, the feeding mechanism 1 can also be omitted, and a manual feeding method can be adopted.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com