Injection end piece with open flow channel and injection molding processing device with the injection end piece

A processing device and an open technology, applied in the direction of coating, etc., can solve problems such as unfavorable clearing procedures, smooth operation, breakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

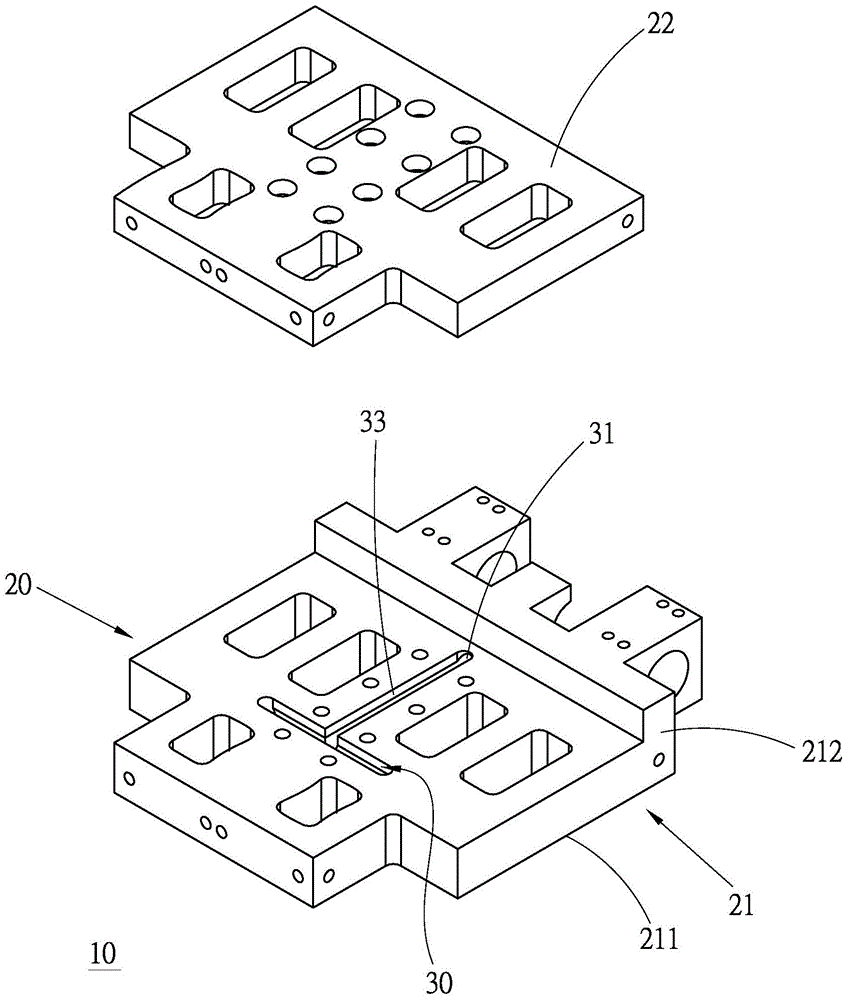

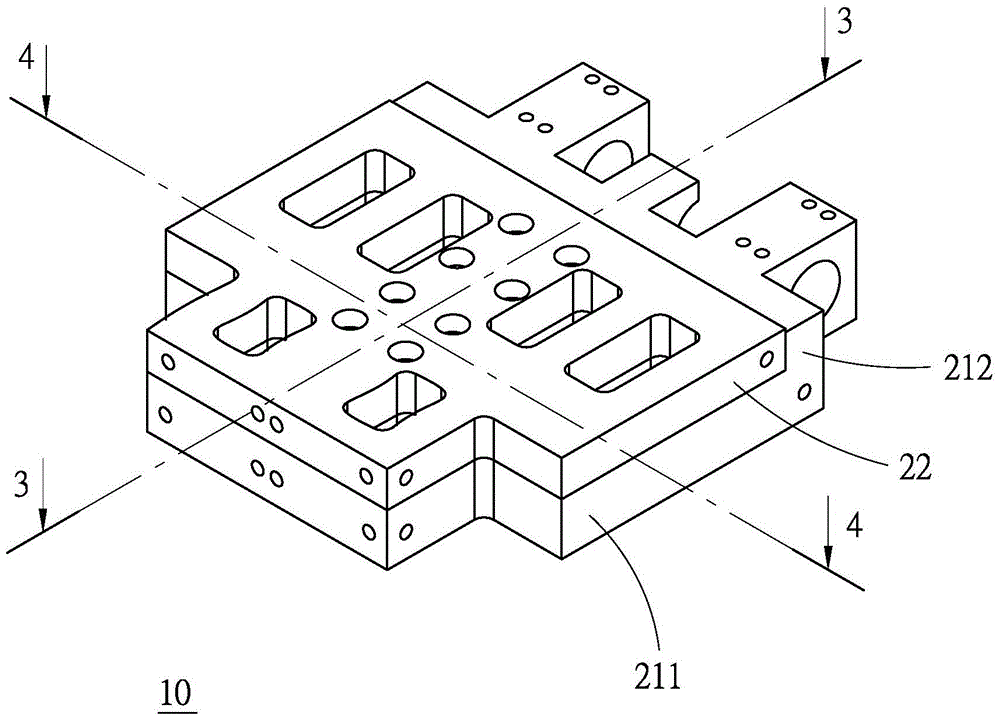

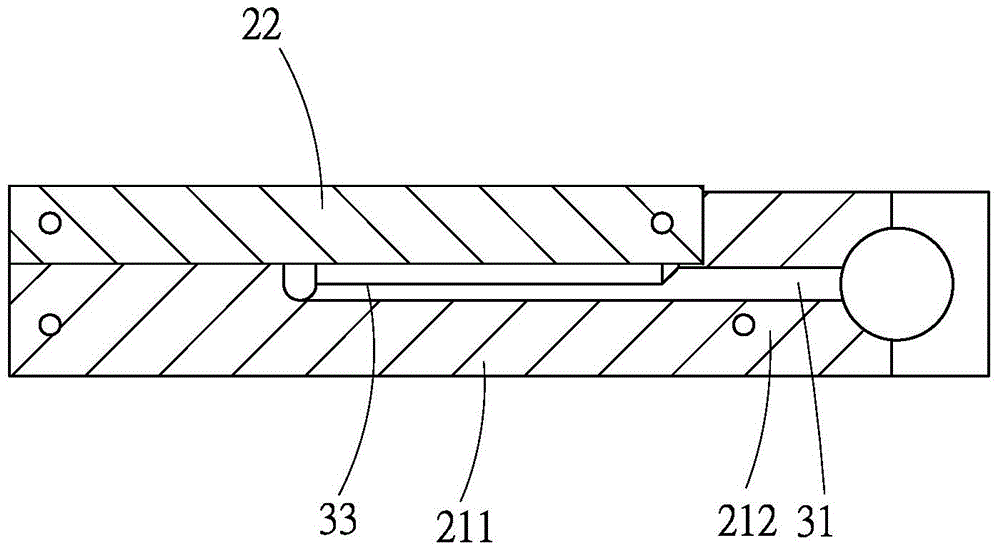

[0035] A preferred embodiment of the present invention is hereby given in conjunction with the drawings, and the specific description is as follows.

[0036] First, see Figure 1 to Figure 4 As shown, the injection end piece 10 provided with an open flow channel in a preferred embodiment of the present invention mainly includes a body 20 and a flow channel 30 .

[0037] The seat body 20 is generally plate-shaped, and has a first seat portion 21 and a second seat portion 22 that overlap each other; wherein, the first seat portion 21 has a plate-shaped first seat body 211 with an appropriate thickness, and a A strip-shaped end wall 212 with a quadrilateral cross-section protrudes from one side plate end of the first seat body 211 on one side of the long axis; the second seat portion 22 is also plate-shaped, and can be attached to the bottom end surface on the upper end surface of the first seat body 211 .

[0038] The flow channel 30 is arranged in the seat body 20 to form a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com