Method of manufacturing color contact lens

A technology for contact lenses and a manufacturing method, which is applied in glasses/protective glasses, glasses/goggles, optics, etc., can solve problems such as eye discomfort, human injury, and poor oxygen permeability, so as to save production costs and time, increase competitiveness, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

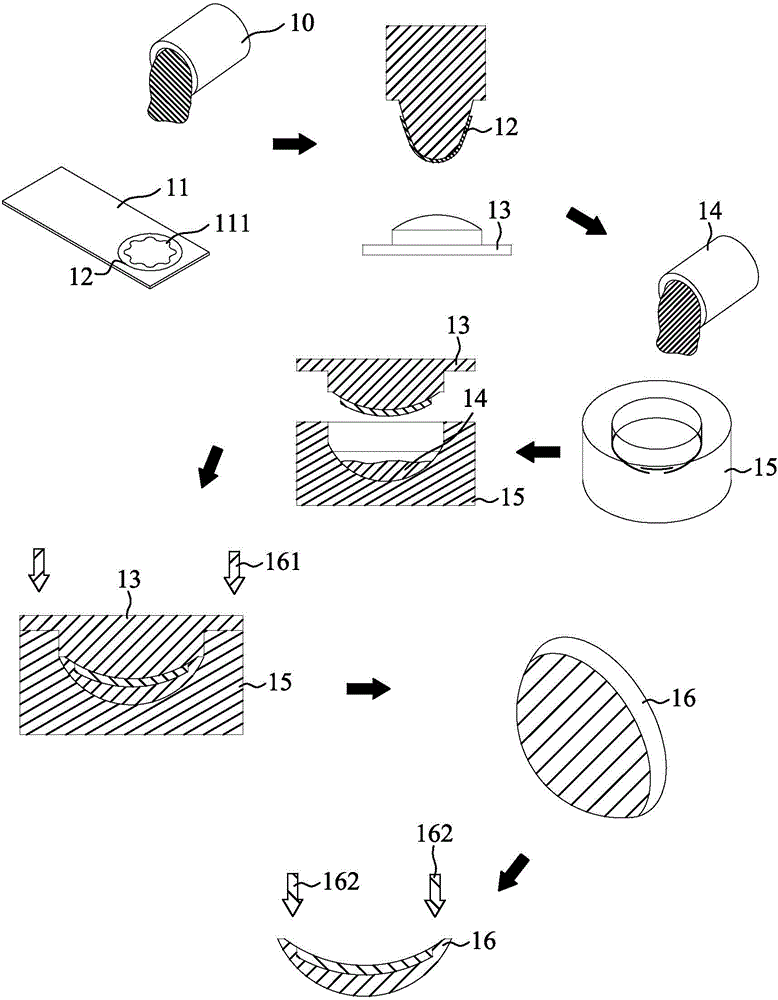

[0062] In order to further have a clear and detailed understanding and understanding of the structure, use and characteristics of the present invention, a preferred embodiment is given, and the detailed description is as follows in conjunction with the accompanying drawings:

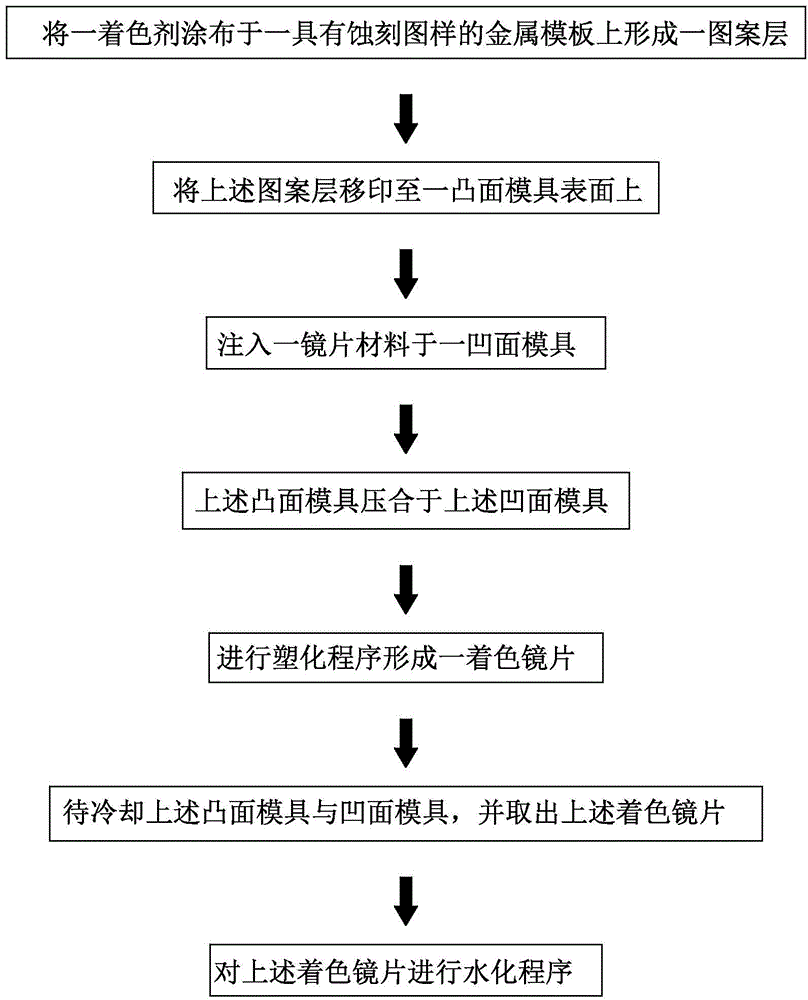

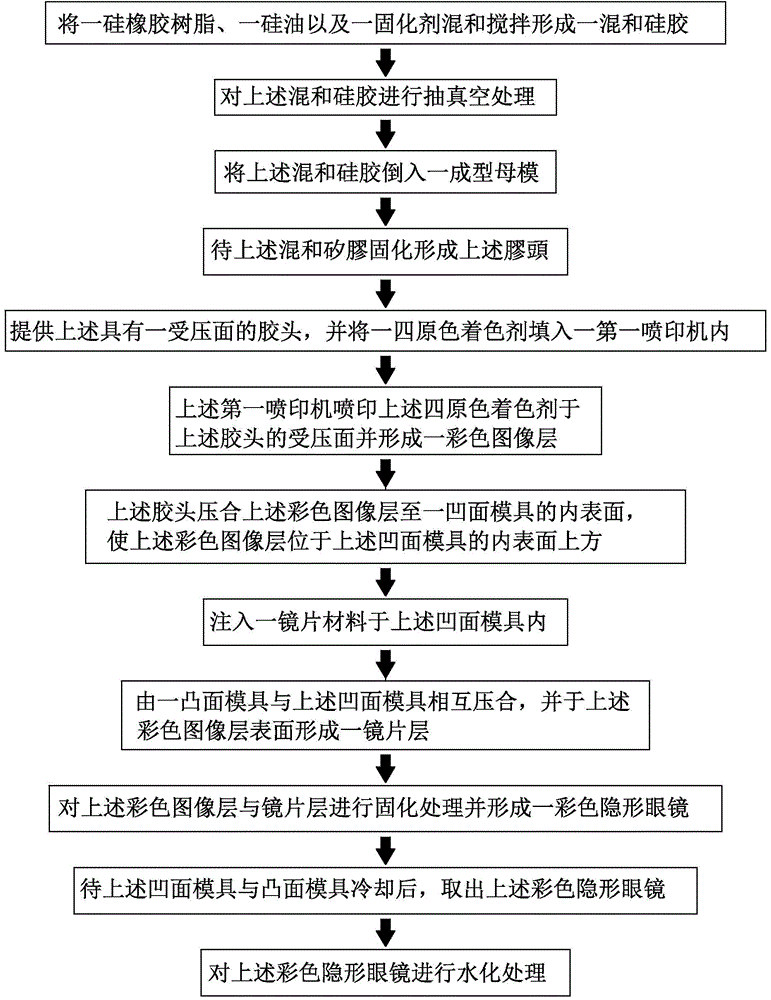

[0063] see Figure 3 to Figure 5 As shown, in the first preferred embodiment, the manufacturing method of the colored contact lens of the present invention comprises the following steps:

[0064] a. Mix and stir the silicone rubber resin 21 , the silicone oil 22 and the curing agent 23 to form a mixed silicone rubber 20 . In a preferred embodiment, firstly, the silicone rubber resin 21 and the silicone oil 22 are mixed evenly, and then the curing agent 23 is added to form the mixed silica gel 20 .

[0065] Wherein, the silicone rubber resin 21 occupies 65-75% of the total volume of the mixed silica gel 20, the silicone oil 22 accounts for 25-30% of the total volume of the mixed silica gel 20, and the cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com