Spinning machine and a false twisting device

A textile machine, false twisting technology, applied in the direction of textiles and papermaking, spinning machine, continuous winding spinning machine, etc., can solve problems such as inability to adjust belt tolerance or wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

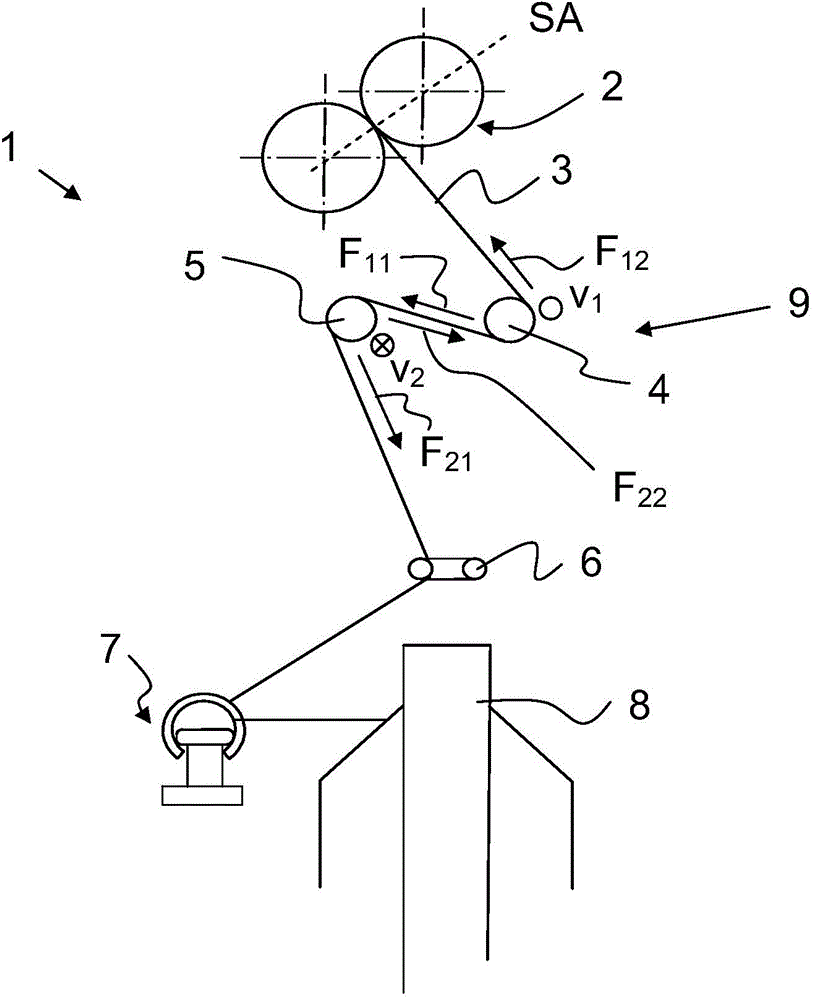

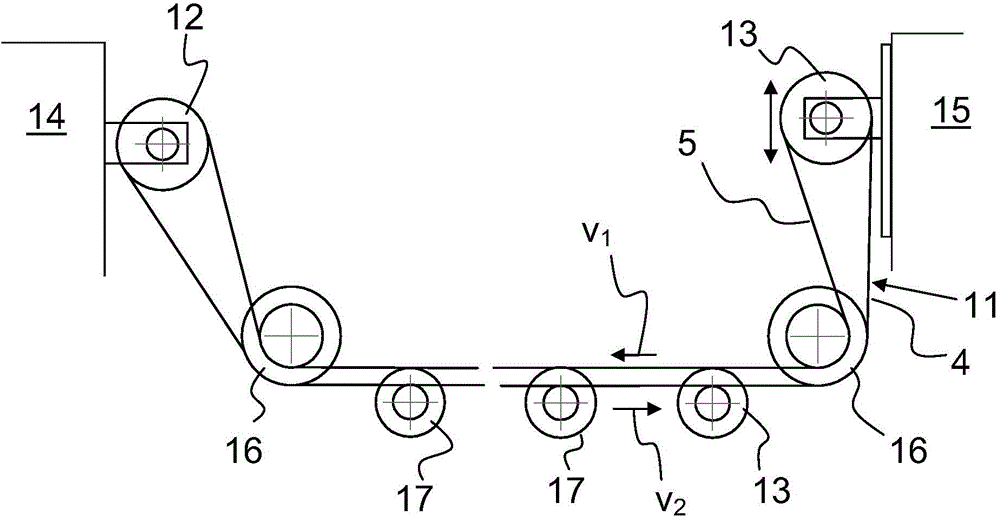

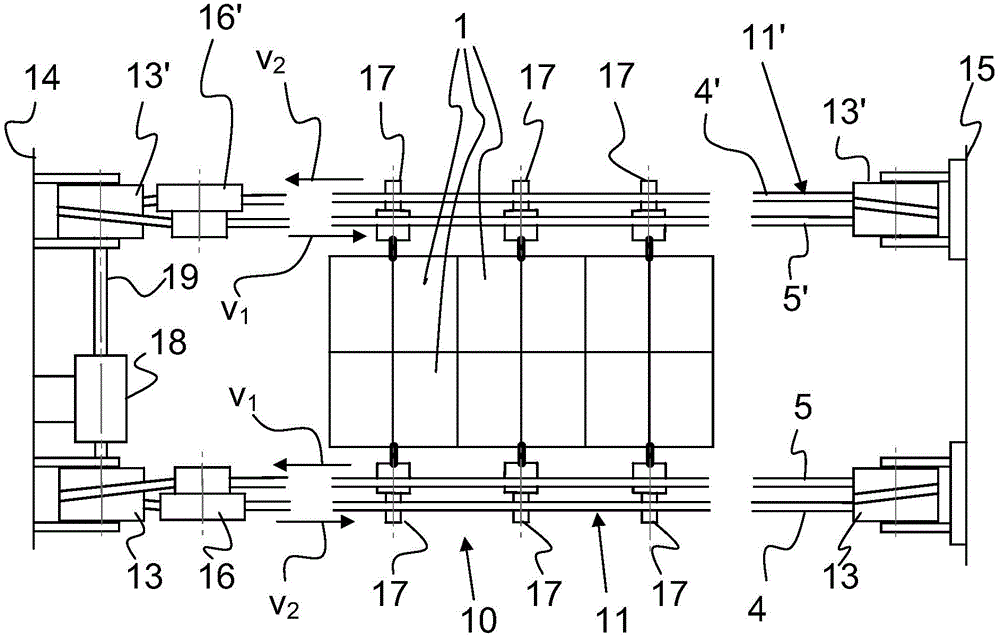

[0042] exist figure 1 The weaving unit 1 of the weaving machine 10 is schematically and partially shown in FIG. The delivery roll pair 2 of the drafting unit, not shown, supplies the ply strand 3 and forms the drafting unit output SA. The strand 3 turns around a first plastic belt 4 and then around a second plastic belt 5 . Subsequently, the ply thread passes through the twist stopper 6 and the traveler 7 and is wound on the bobbin 8 . The first plastic belt 4 and the second plastic belt 5 form a false twist device 9 . The two plastic belts 4 and 5 can refer to two separate belts 4 and 5 or to stretching and pushing return sections of a single belt.

[0043] The first plastic belt 4 and the second plastic belt 5 or the two runs have opposite directions of movement. Since the yarn lies flat on two belts moving in opposite directions, the yarn is stretched in one direction by one return and in the other direction by the other return. The yarn is deflected in the direction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com