Multilayer rolling bearing

A technology of rolling bearings and rolling elements, which is applied in the field of rolling bearings, and can solve problems such as loss of normal working ability, pits, and peeling off of surface metal sheets, so as to reduce the number of stress cycles, improve safety, and reduce the number of rolling times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The multilayer rolling bearing of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

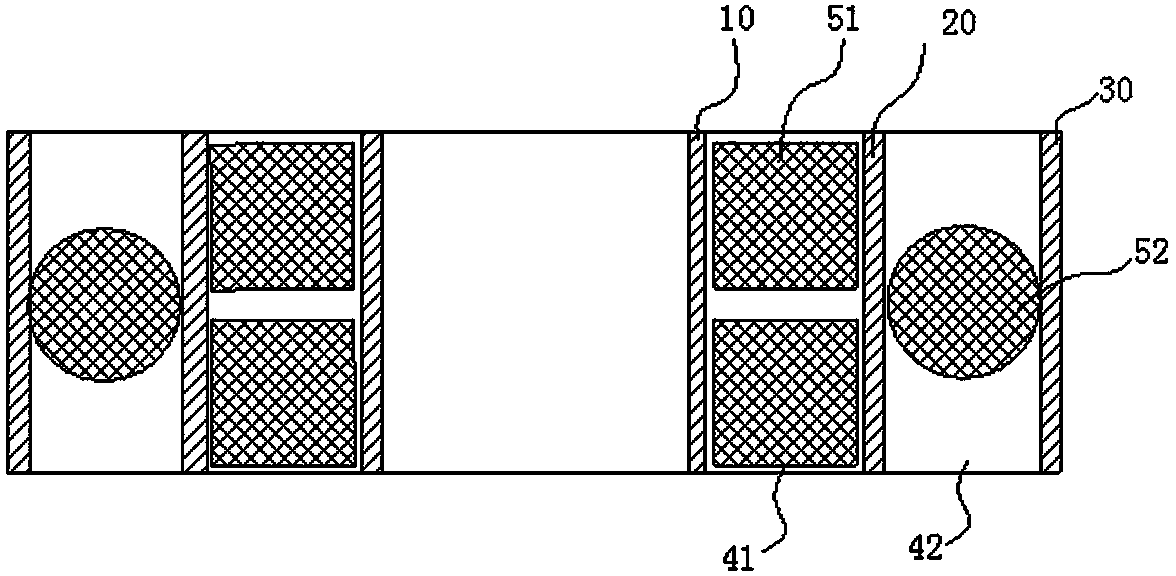

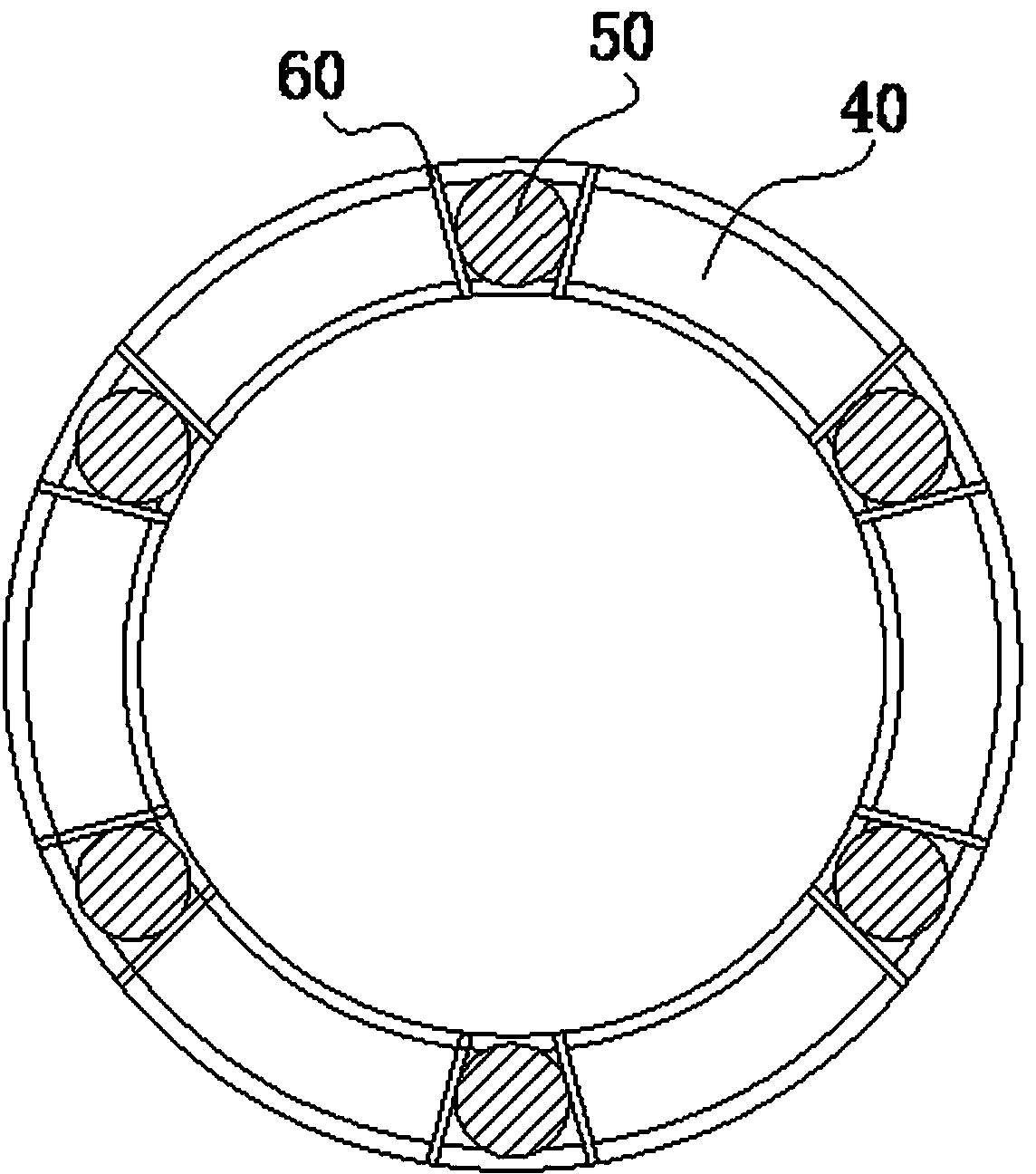

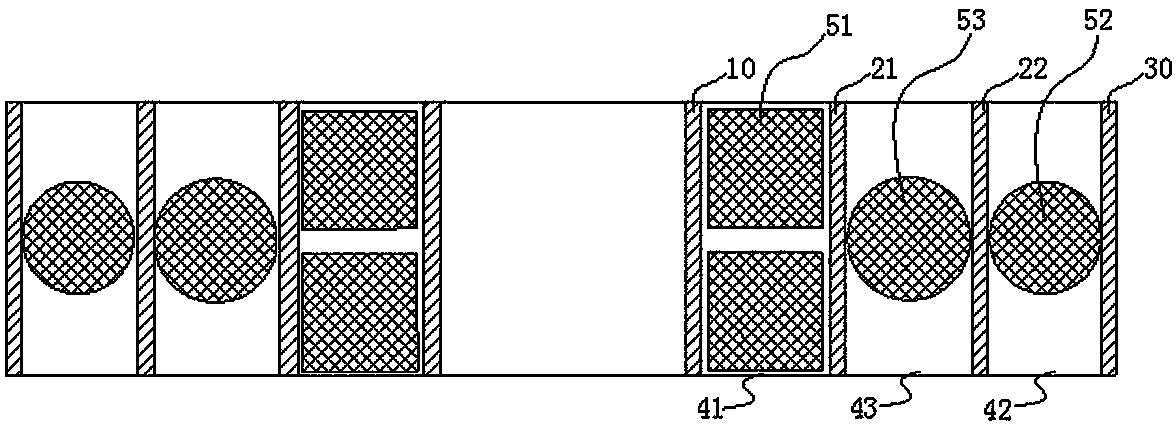

[0013] The present invention provides a multilayer rolling bearing, which includes an inner ring 10 , at least one intermediate ring 20 , an outer ring 30 and at least two rolling layers 40 . The structure of multiple rolling layers 40 can effectively reduce the rolling times of the rolling body 50 on the inner and outer rings during the rolling process, reduce the number of stress cycles, and thus increase the service life of the bearing.

[0014] The rolling layer 40 includes an inner rolling layer 41 and an outer rolling layer 42 ; the inner rolling layer 41 is located between the inner ring 10 and the middle ring 20 , and the outer rolling layer 42 is located between the middle ring 20 and the outer ring 30 .

[0015] Each rolling layer 40 includes rolling bodies 50 and cages 60 ; wherein the cages 60 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com