Ventilation detection mechanism

A detection mechanism and detection mold technology, applied in the direction of measuring device, fluid tightness test, machine/structural component test, etc., can solve the problems of difficult measurement, low operation efficiency, poor measurement accuracy, etc., and overcome cumbersome operation , fast speed and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing.

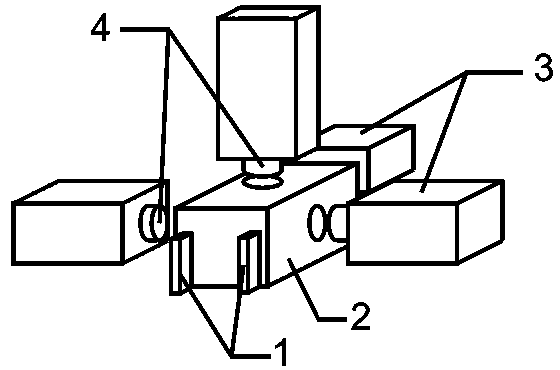

[0014] The ventilation detection mechanism includes a fixed plate 1, a detection mold 2, a detection motor 3, and a detection head 4. It is characterized in that the detection mold 2 is fixed by the fixed plate 1, a plurality of detection motors 3 are distributed around the detection mold 2, and the detection motor 3 is close to the detection One end of the mold 2 is provided with a detection head 4, and the corresponding position of the detection mold 2 is provided with an opening, which can be inserted into the detection head 4 to detect the workpiece. Feed in from below and form a relatively airtight space with the jig. There are four detection motors 3, which are respectively arranged on the top, left, right and rear of the detection mold 2. The detection motor 3 is preferably a servo drive motor. The detection motor 3 is preferably a double-station drive motor.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com