Method for manufacturing antenna part

A technology for antenna elements and manufacturing methods, applied in antennas, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of increased manufacturing hours, higher manufacturing costs, and more parts, and achieve improved price advantages and productivity Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Hereinafter, an embodiment for implementing the present invention (hereinafter, referred to as an "embodiment") will be described in detail with reference to the accompanying drawings.

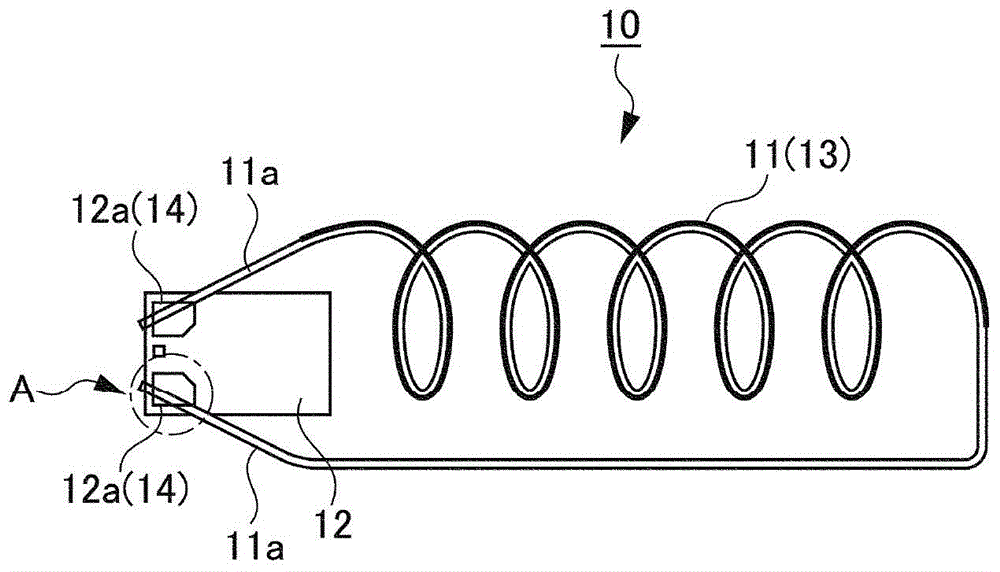

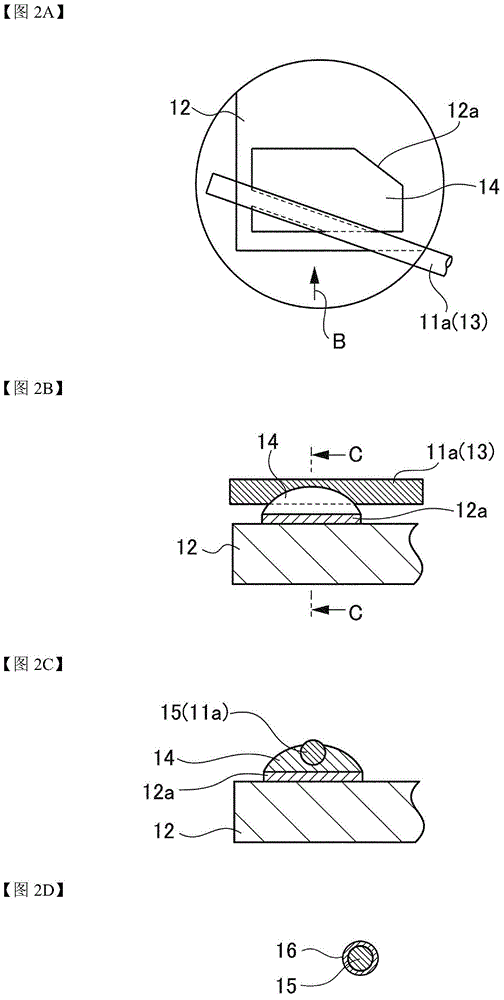

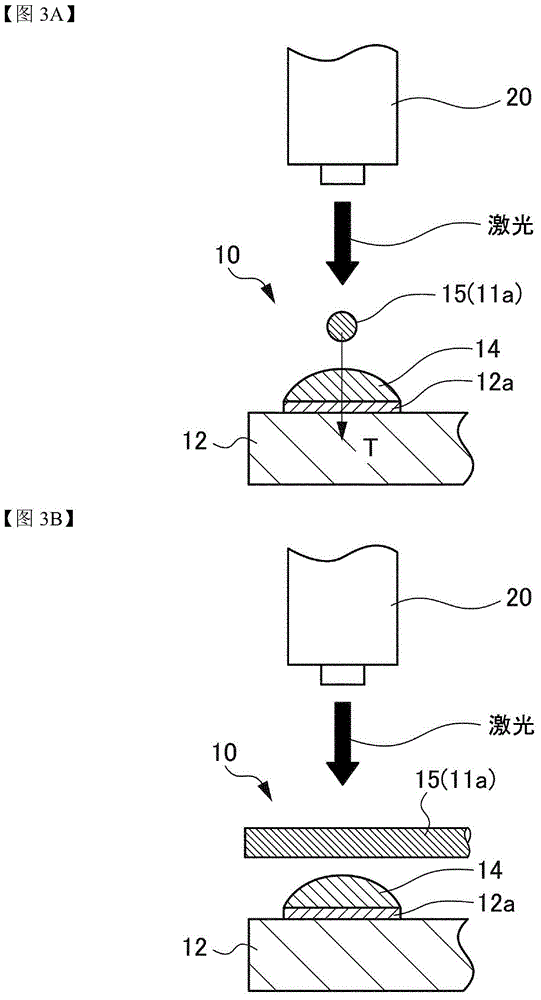

[0025] figure 1 Shown is a schematic diagram of an example of an antenna element manufactured by applying the manufacturing method according to the present invention. In this figure, the antenna element 10 includes a coil member 11 and a semiconductor substrate 12 .

[0026] The coil component 11 is a coil-shaped antenna coil formed by winding a wire 13 with a predetermined number of turns, and connecting ends 11 a and 11 a are led out at both ends thereof as connecting portions for connecting with the semiconductor substrate 12 , respectively. connect.

[0027] The semiconductor substrate 12 is an IC chip, and a part of the upper surface thereof is provided with conductive terminals, ie, pads 12a and 12a, which are connection regions, and the conductive terminals are formed of condu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com