Fluid-dynamic device and fuel feed system comprising said fluid-dynamic device

A fuel supply system, fluid dynamics technology, applied in the direction of charging system, liquid fuel feeder, fuel injection pump, etc., can solve the problems of incomplete solution, opening, etc., and achieve the effect of reducing workload and reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

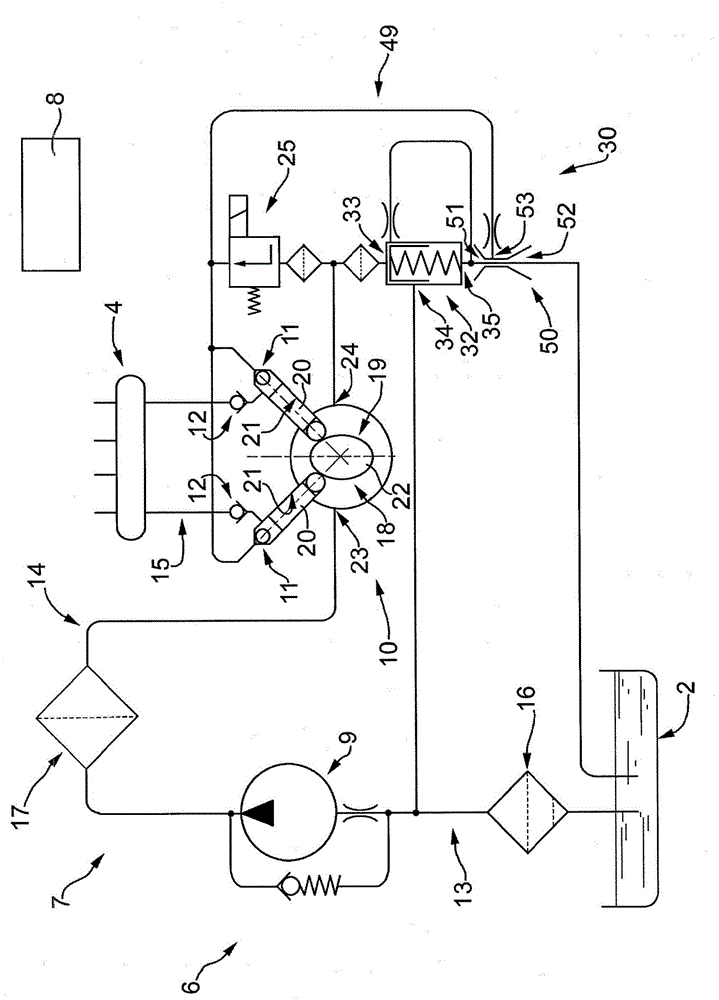

[0029] refer to figure 1 , reference numeral 1 denotes a system for supplying fuel from a fuel tank to an internal combustion engine.

[0030] refer to figure 1 , reference numeral 1 designates in its entirety a system for feeding fuel (diesel fuel in the case in question) from a fuel tank 2 to an internal combustion engine of known type (not shown).

[0031] In more detail, the internal combustion engine is a diesel engine comprising a manifold 4 for distributing fuel (commonly called "common rail") and a series of electrically operated injectors (not shown), said manifold Designed to accommodate fuel with a pressure preferably (but not necessarily) greater than 1800 bar; said injectors are directly connected to the common rail 4 and are operable to dissipate the fuel mist in each combustion chamber of an internal combustion engine (not shown) change.

[0032] refer to figure 1 The fuel supply system 1 generally comprises a fuel pump unit 6, a hydraulic circuit 7, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com