Urban household garbage crushing machine

A technology for municipal solid waste and crusher, which is applied in presses, presses using rotary pressure components, and grain processing, etc., can solve the problems of inconvenient incineration and sorting, uneven particle size, and different degrees of adaptation. Eliminate the phenomenon of winding shaft, solve the effect of continuous feeding and avoid stopping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

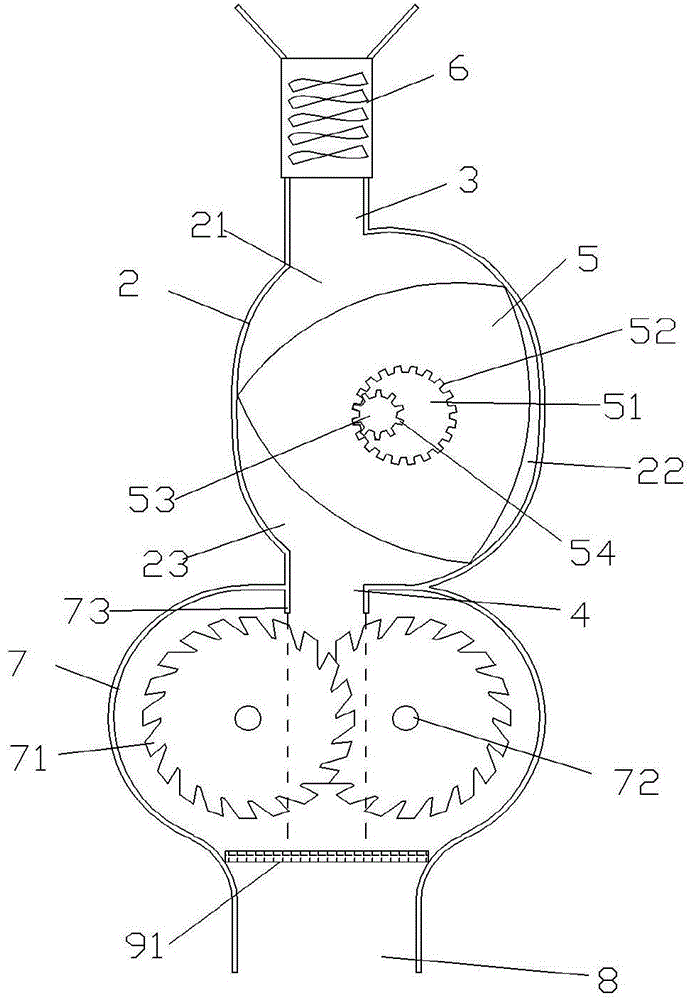

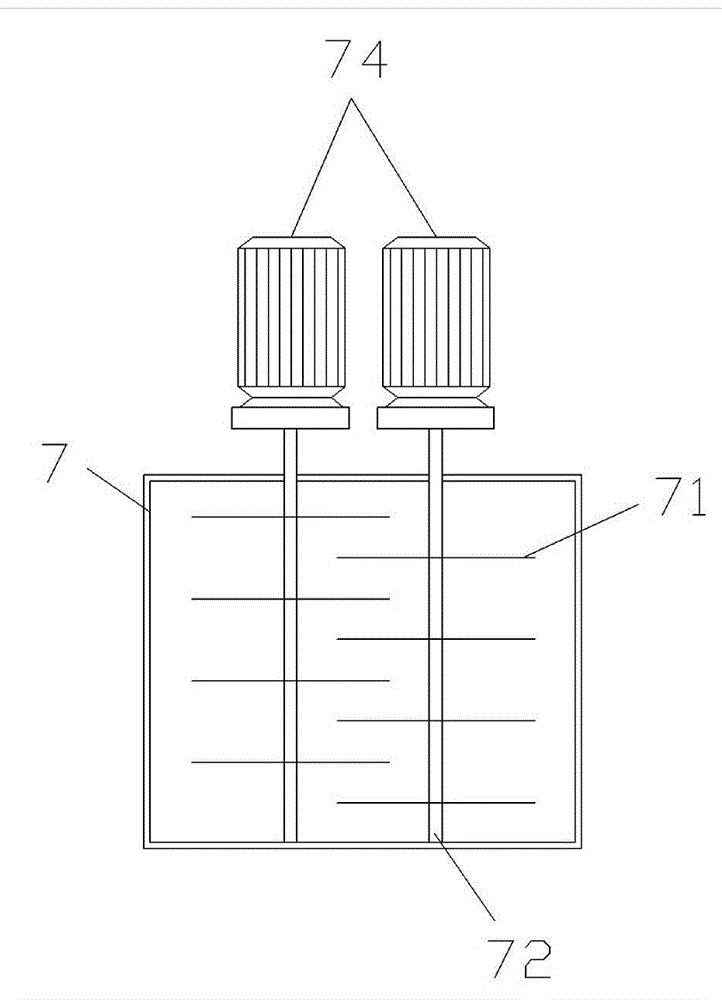

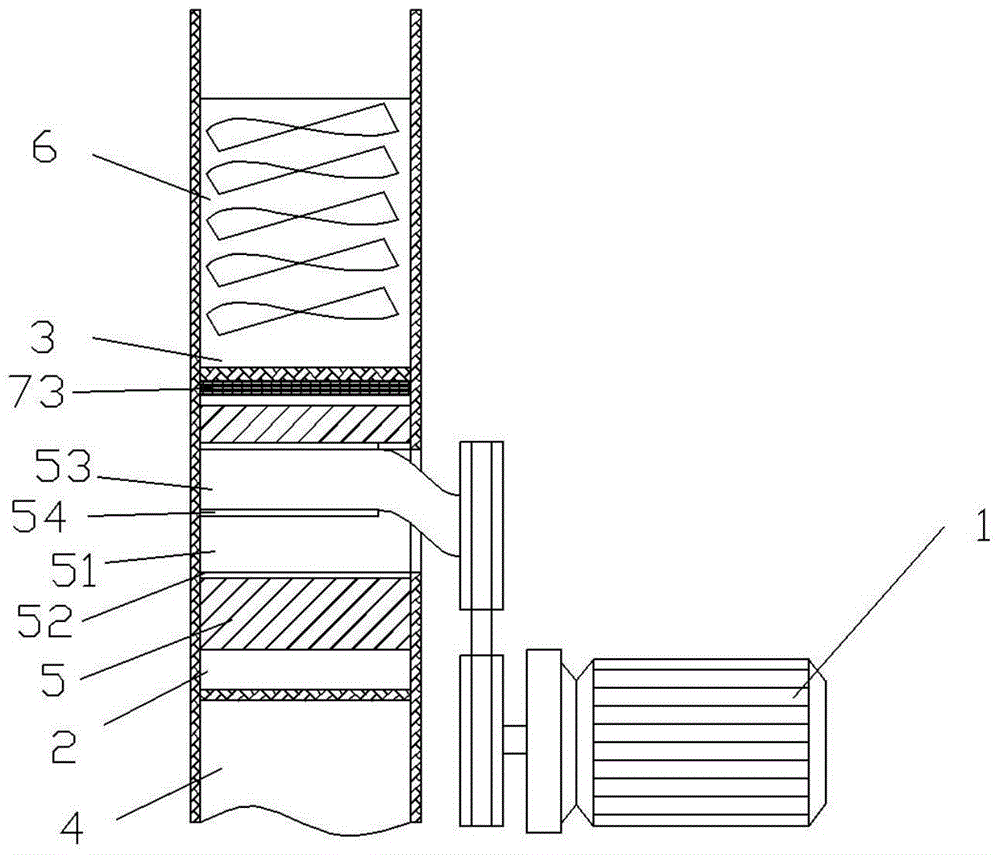

[0023] A municipal solid waste crusher, comprising a feed port 3, a compression chamber 2, a crushing chamber 7, a discharge port 8 and a compression motor 1, the compression chamber 2 is arranged between the feed port 3 and the crushing chamber 7, and the crushing chamber 7 A discharge port 8 is provided at the bottom, a discharge port 4 is provided at the contact part between the compression chamber 2 and the crushing chamber 7, and a crushing blade 71 is provided in the crushing chamber 7, and the crushing blade 71 is connected with a crushing motor 74 through a knife shaft 72, and the characteristics are as foll...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com