Separated inertia vibrator

A vibrator and split-type technology, which is applied in the direction of using vibrating fluid, can solve the problems of delaying production, affecting the use effect, difficult to match the electromagnetic parameters of the two motors, and achieving the effect of reducing energy consumption and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

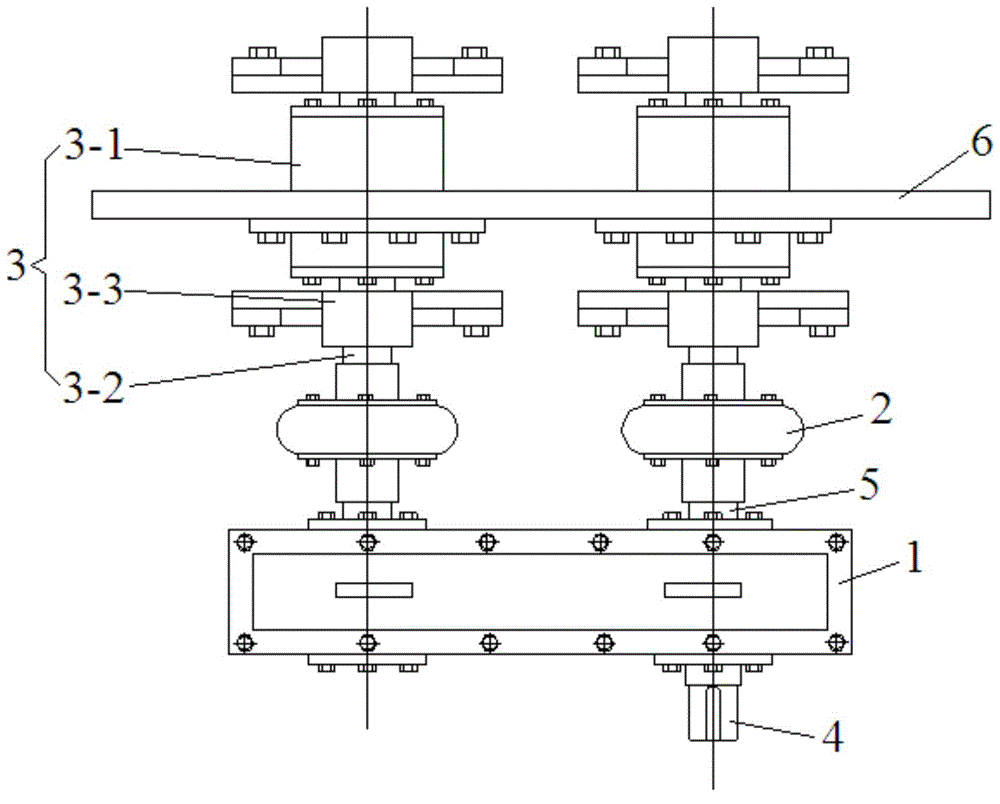

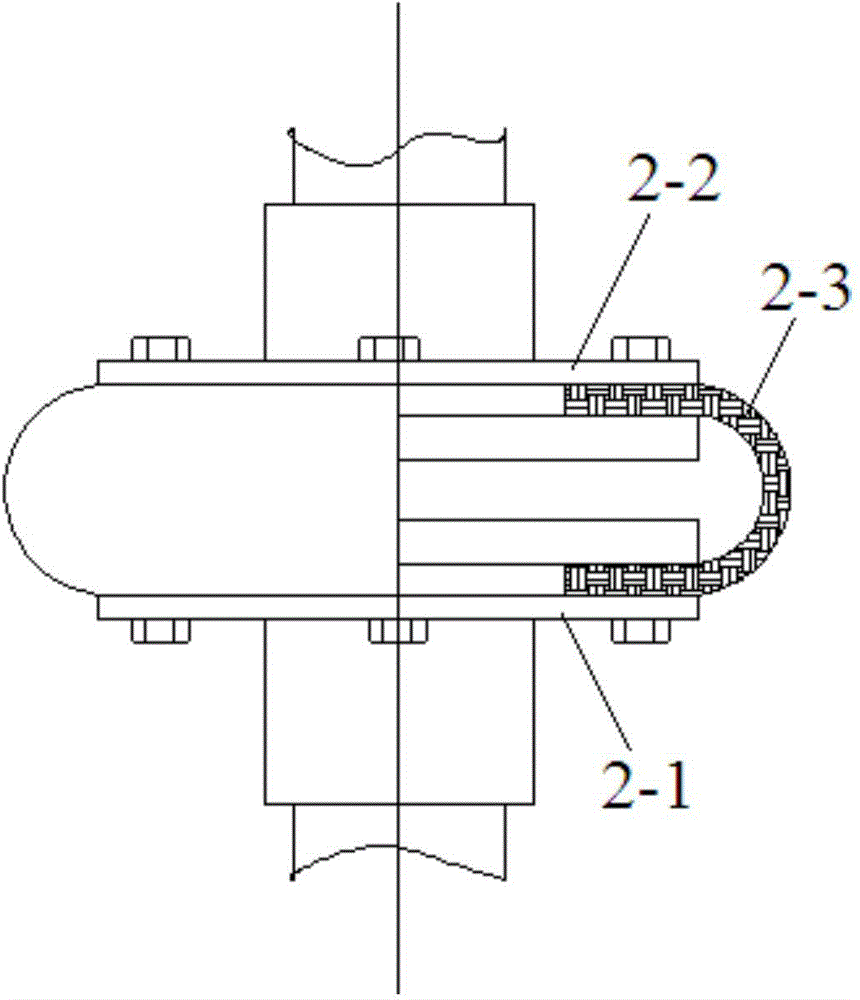

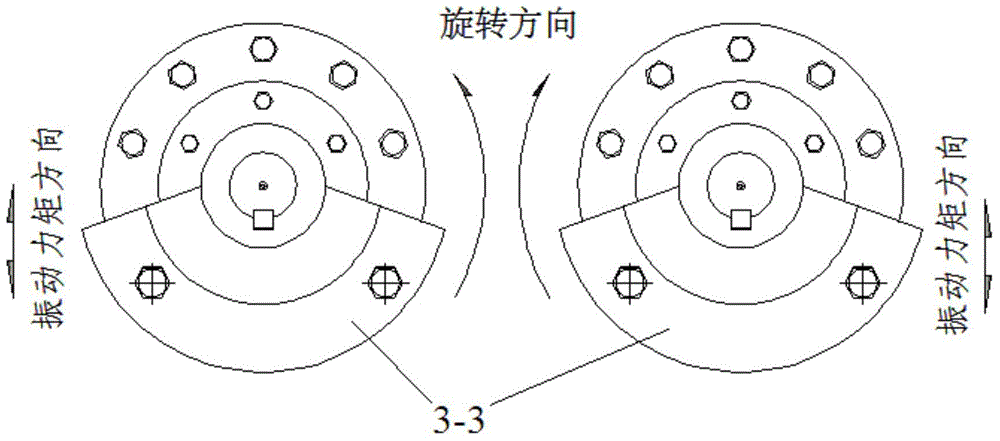

[0015] Referring to the accompanying drawings, a split inertial vibrator includes a transfer gearbox 1, two softly connected separate shaft couplings 2 and two vibration mechanisms 3, and the transfer gearbox 1 has a power input shaft 4 and two A power take-off shaft 5, two power take-off shafts 5 rotate in opposite directions, and two softly connected separate couplings 2 respectively include a driving coupling 2-1, a driven coupling 2-2 and a driving coupling 2-1 and a driven coupling 2-2. The software connector 2-3 between the driven linkage 2-2, the two vibration mechanisms 3 respectively include a bearing housing 3-1, a main shaft 3-2 and a vibrating block 3-3 installed on the main shaft 3-2, two The bearing housing 3-1 of a vibration mechanism 3 is installed on the installation mechanism 6 in parallel; the two power output shafts 5 are respectively connected with the active coupling 2-1 of the two soft-connected separate shaft couplings 2, and the two soft-connected The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com