Telescopic ingot solidification terminal electromagnetic stirring device

A technology of electromagnetic stirring and solidification end, which is applied in the field of electromagnetic stirring device at the end of casting slab solidification, which can solve the problems of porosity and shrinkage cavity, and achieve the effects of reducing the depth of liquid cave, eliminating central segregation, and inhibiting segregation channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

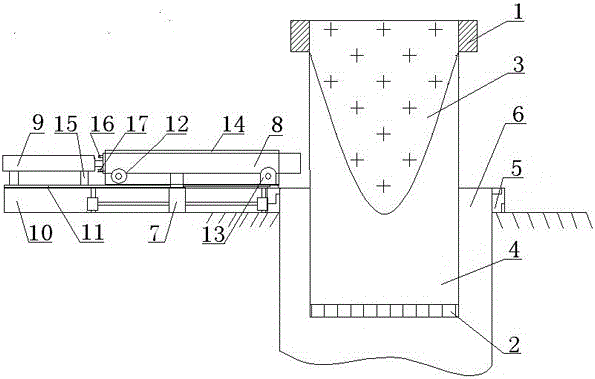

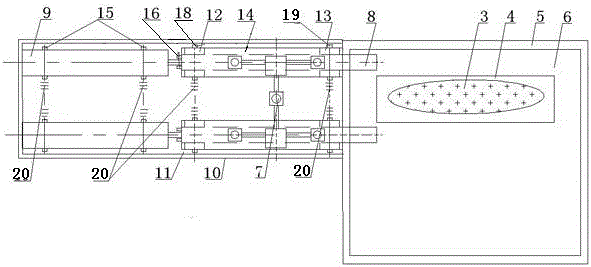

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1 and 2 As shown, the telescopic ingot solidification end electromagnetic stirring device, the telescopic ingot solidification end electromagnetic stirring device is fixed on the ground outside the casting well 6, and the device includes two sets of parallel electromagnetic stirring devices 14, a pneumatic device And the worm gear lifting device 7, and is symmetrical about the longitudinal section of the ingot solidification end; one end of the electromagnetic stirrer 8 located in the electromagnetic stirring device 14 is movably connected with the cylinder 9 located in the pneumatic device, and the other end of the electromagnetic stirrer 8 is arranged on the ingot One side of the solidified end; the electromagnetic stirring device 14 is movably arranged at one end of the load-bearing steel plate 11, and the pneumatic device is fixedly...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap