Supersonic atomizing nozzle with two-stage laval and hartmann combined structure

An atomization nozzle, supersonic technology, applied in the field of supersonic atomization nozzle, can solve the problems such as no nozzle, achieve the effect of high atomization efficiency, narrow particle size distribution, and fine atomization particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

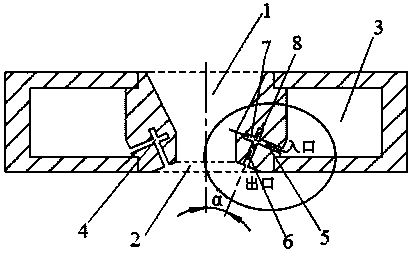

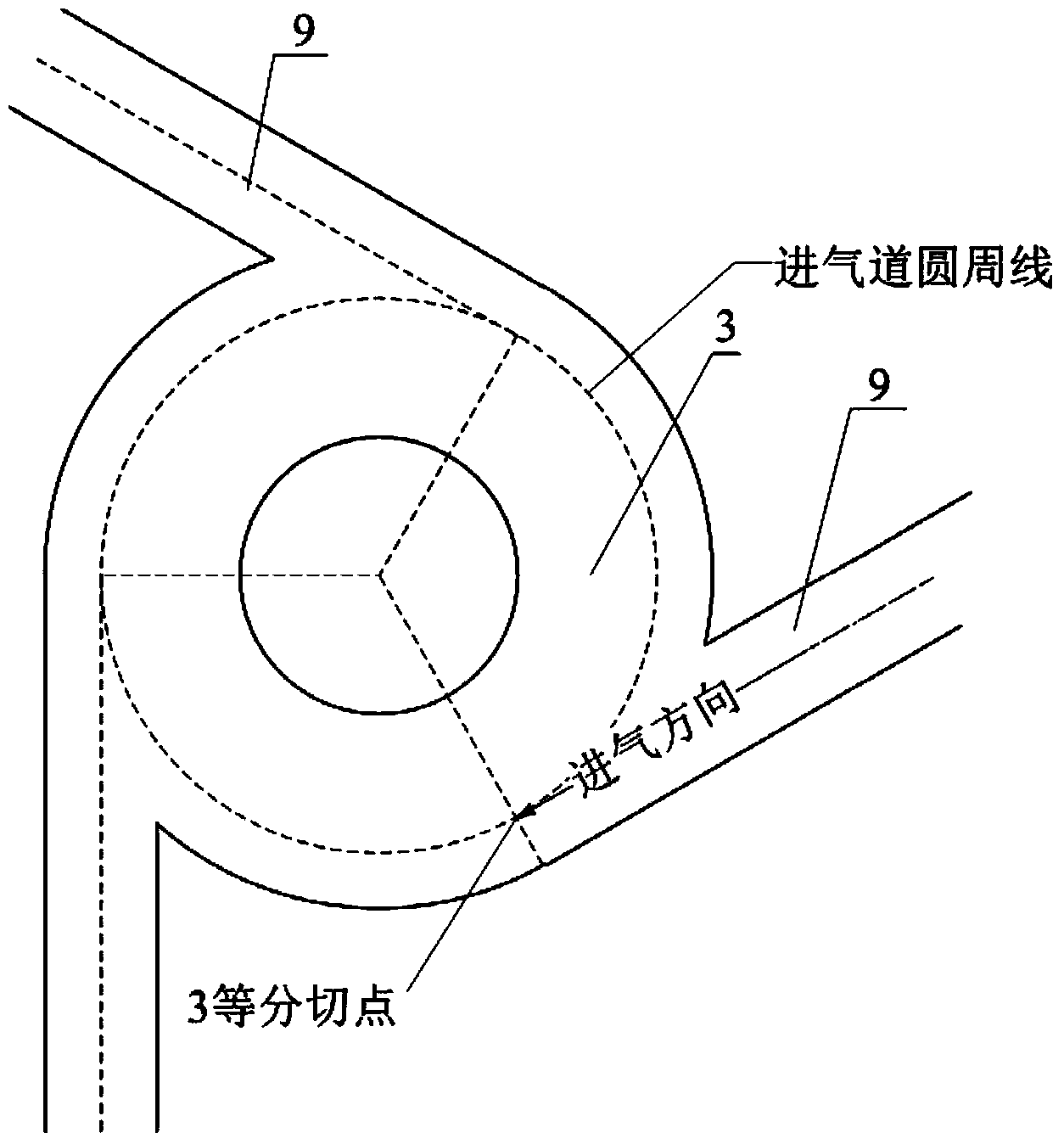

[0030] A supersonic atomizing nozzle with two-stage laval and hartmann structure fusion, such as figure 1 As shown, it includes a liquid guiding chamber 1, a nozzle opening 2 is provided below the liquid guiding chamber 1, an annular high-pressure air inlet chamber 3 is surrounded around the liquid guiding chamber 1, and an air inlet channel is opened on the inner wall of the high-pressure air inlet chamber 3 4. The high-pressure intake chamber 3 communicates with the nozzle opening 2 through the intake passage 4, and the number of the intake passage 4 is greater than 18.

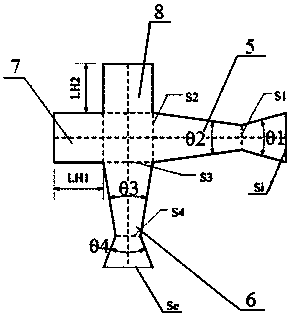

[0031] refer to figure 1 , figure 2 , the intake channel 4 is a crossed Hartmann two-stage resonance tube structure formed by connecting the inlet conduit 5, the outlet conduit 6, the primary resonance tube 7 and the secondary resonance tube 8, wherein the inlet conduit 5 and the primary resonance tube 7 are located On the same straight line, the outlet conduit 6 and the secondary resonance tube 8 are lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com