Full-hydraulic drive open-type double-main-shaft numerical control underwater stitch welding equipment

A dual-spindle, fully hydraulic technology, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve the problems of small operating space, unstable work, small repair range, etc., to achieve accurate and reliable work, accurate and reliable drive, The effect of repairing a large area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

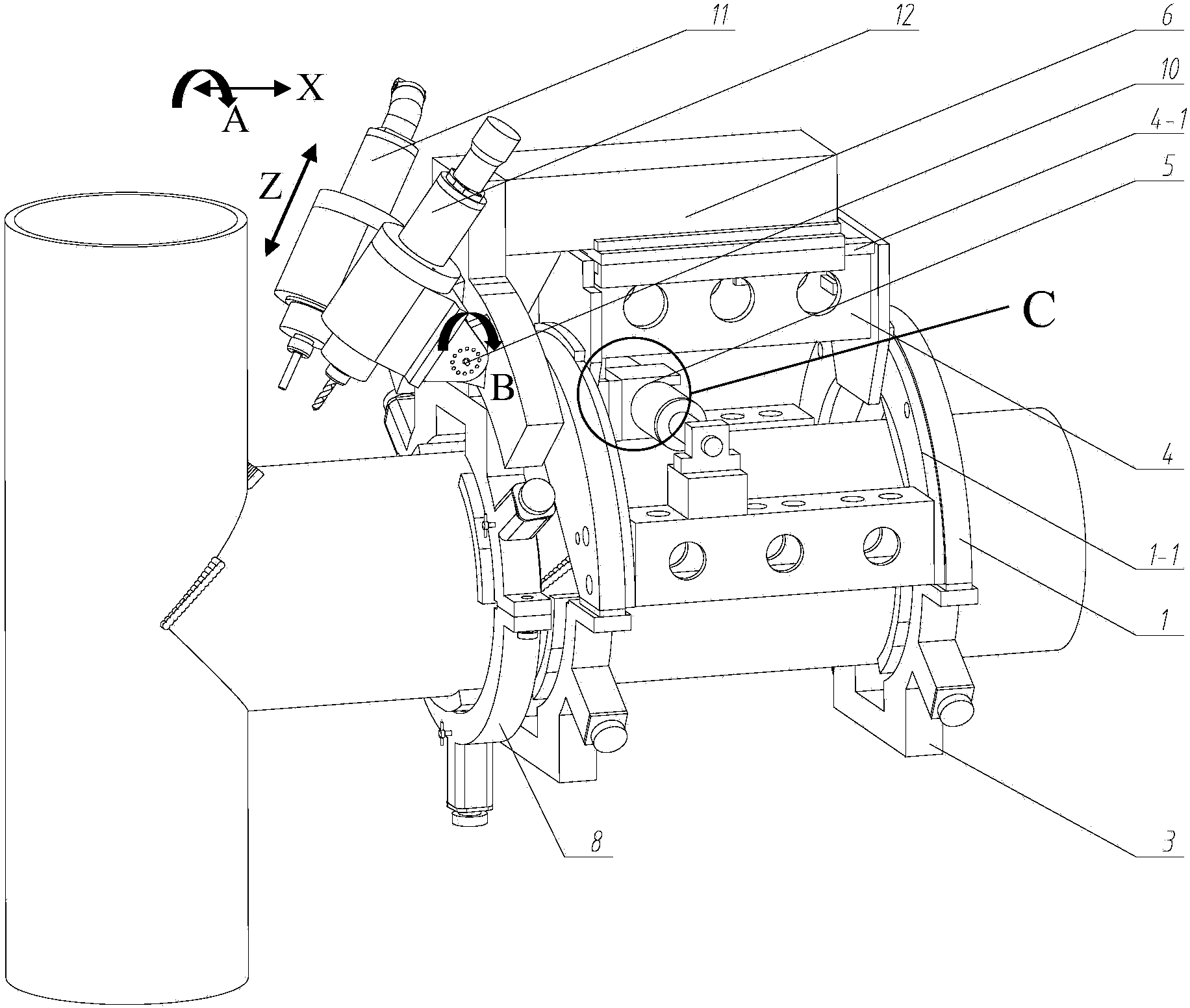

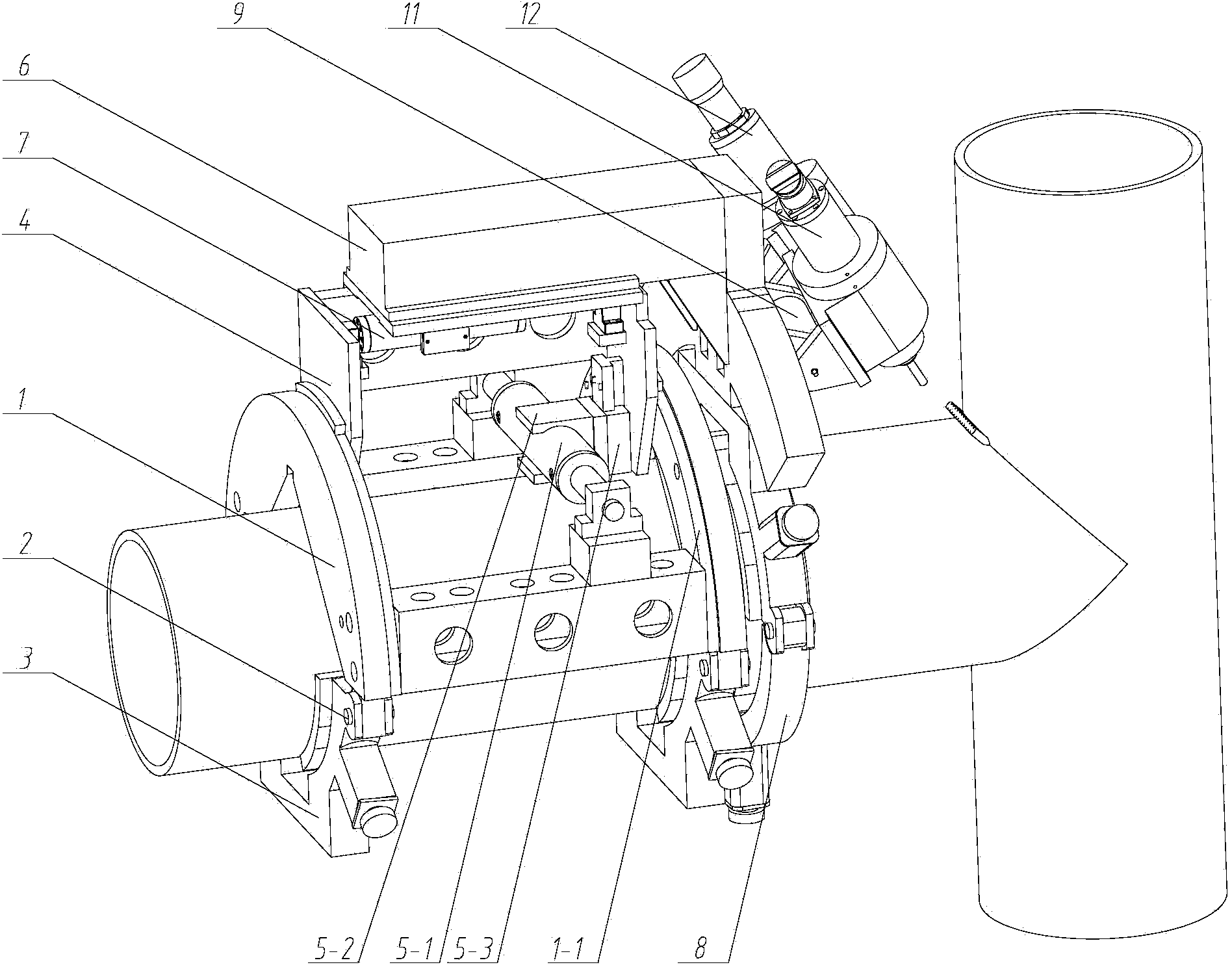

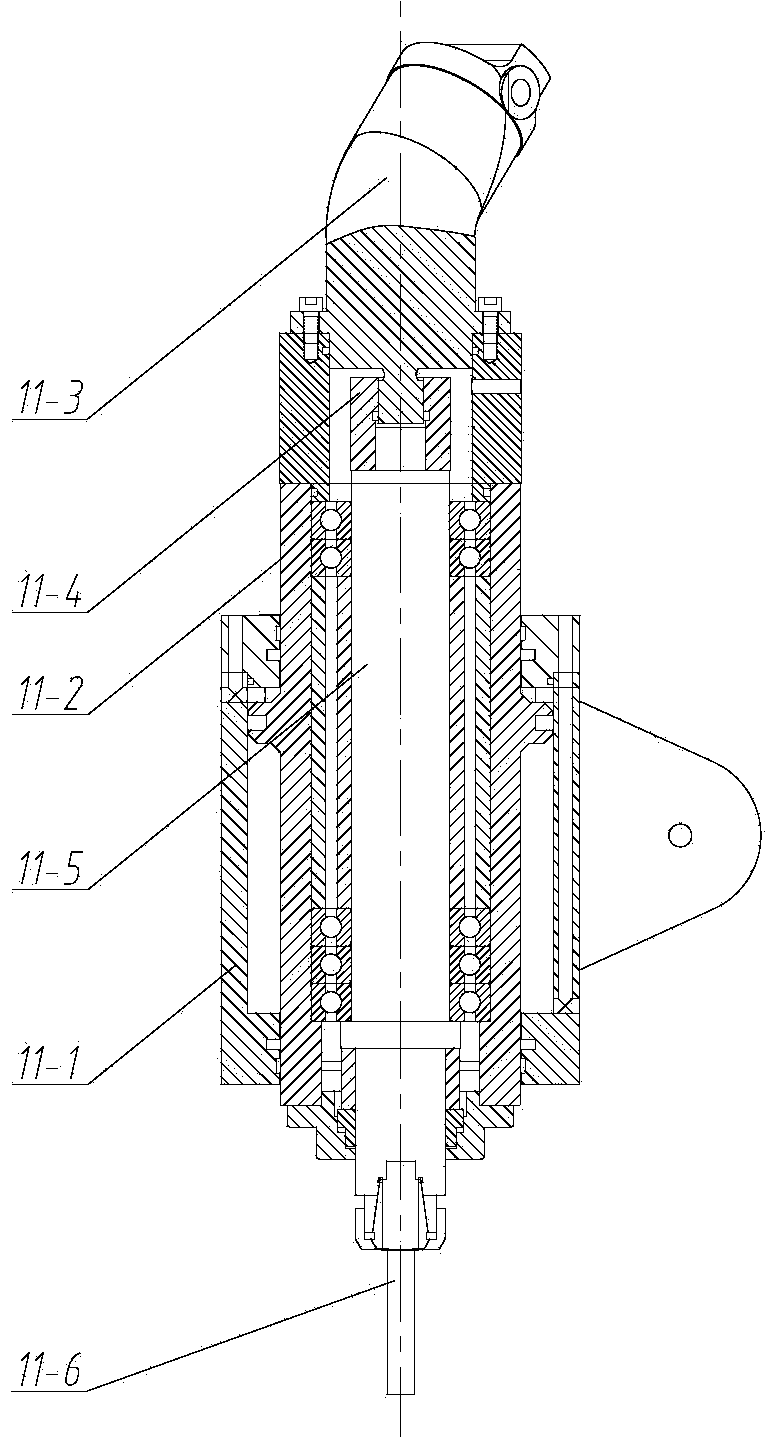

[0030] see Figure 1 to Figure 7 , a full-hydraulic drive open-type dual-spindle CNC underwater friction welding equipment, including two sets of positioning and clamping mechanisms arranged symmetrically on the left and right, straddling the two sets of positioning and clamping mechanisms and slidingly connected with them along the circumferential direction The mobile support frame 4 is provided with a set of circumferential movement mechanism 5 connected with the mobile support frame 4 between the two sets of positioning and clamping mechanisms. The cantilever beam 6 that is slidingly connected is fixed with an auxiliary support frame 8 under the cantilever end of the cantilever beam 6, and the auxiliary support frame is vacantly sleeved on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com