A kind of self-diffusion nano iron composite material and its preparation method and use

A composite material and nano-iron technology, which is applied in the field of self-diffusion nano-iron composite material and its preparation, can solve the problems of poor diffusion ability, poor diffusion ability and restricted mobility of magnetic biochar-supported nano-iron, and achieve a simple and reliable process. , Strong self-diffusion ability, the effect of expanding the repair range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

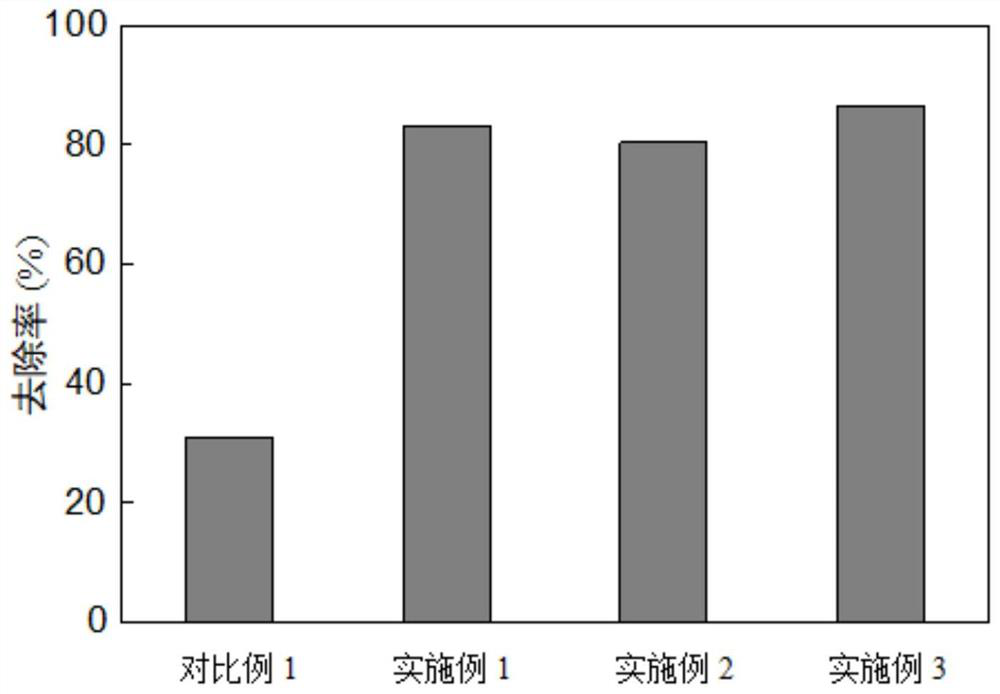

Examples

Embodiment 1

[0059] A preparation method of self-diffusion nano-iron composite material, said preparation method comprising the following steps:

[0060] (1) Glucose and water are mixed in a polytetrafluoroethylene-lined hydrothermal reaction kettle at a mass ratio of 10:1, nitrogen is blown and the temperature is programmed to 100°C under stirring conditions, and the sugar raw material is turned into syrup , adding nano-iron to the reactor, and stirring evenly, then sealing the reactor, the mass ratio of the nano-iron to glucose is 1:1;

[0061] (2) Feed nitrogen to make the nitrogen pressure in the reactor be 40 atmospheres and continue to heat up to 150°C, and keep it for 40min; at this time, the water content in the syrup will slowly decrease, and nitrogen will be mixed with Numerous tiny high-pressure bubbles are formed inside the slurry of nano-iron;

[0062] (3) The heating of the hydrothermal reaction kettle is stopped, and a nitrogen environment with a pressure of 40 atmospheres ...

Embodiment 2

[0065] A preparation method of self-diffusion nano-iron composite material, said preparation method comprising the following steps:

[0066] (1) Mix sucrose and water in a polytetrafluoroethylene-lined hydrothermal reaction kettle at a mass ratio of 10:1, blow nitrogen and program the temperature to 100°C under stirring conditions, and wait until the sugar raw materials are turned into syrup , adding nano-iron to the reactor, and stirring evenly, then sealing the reactor, the mass ratio of the nano-iron to sucrose is 1:1;

[0067] (2) Feed nitrogen to make the nitrogen pressure in the reactor be 40 atmospheres and continue to heat up to 150°C, and keep it for 40min; at this time, the water content in the syrup will slowly decrease, and nitrogen will be mixed with Numerous tiny high-pressure bubbles are formed inside the slurry of nano-iron;

[0068] (3) The heating of the hydrothermal reaction kettle is stopped, and the nitrogen environment with a pressure of 40 atmospheres i...

Embodiment 3

[0071] A preparation method of self-diffusion nano-iron composite material, said preparation method comprising the following steps:

[0072] (1) Maltose and water are mixed in a polytetrafluoroethylene-lined hydrothermal reaction kettle at a mass ratio of 10:1, nitrogen is blown and the temperature is programmed to 100°C under stirring conditions, and the sugar raw materials are turned into syrup. , adding nano-iron to the reactor, and stirring evenly, then sealing the reactor, the mass ratio of the nano-iron to maltose is 1:1;

[0073] (2) Feed nitrogen to make the nitrogen pressure in the reactor be 40 atmospheres and continue to heat up to 150°C, and keep it for 40min; at this time, the water content in the syrup will slowly decrease, and nitrogen will be mixed with Numerous tiny high-pressure bubbles are formed inside the slurry of nano-iron;

[0074] (3) The heating of the hydrothermal reaction kettle is stopped, and the nitrogen environment with a pressure of 40 atmosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com