Floating equal-height pad assembly for vertical drilling machine

A vertical drilling machine and contour pad technology, applied in metal processing machinery parts, clamping, supporting and other directions, can solve the problems of drilling error, workpiece swing, inability to reliably press the workpiece, etc., and achieve the effect of avoiding swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In the following, the present invention will be further explained through the embodiments and the accompanying drawings:

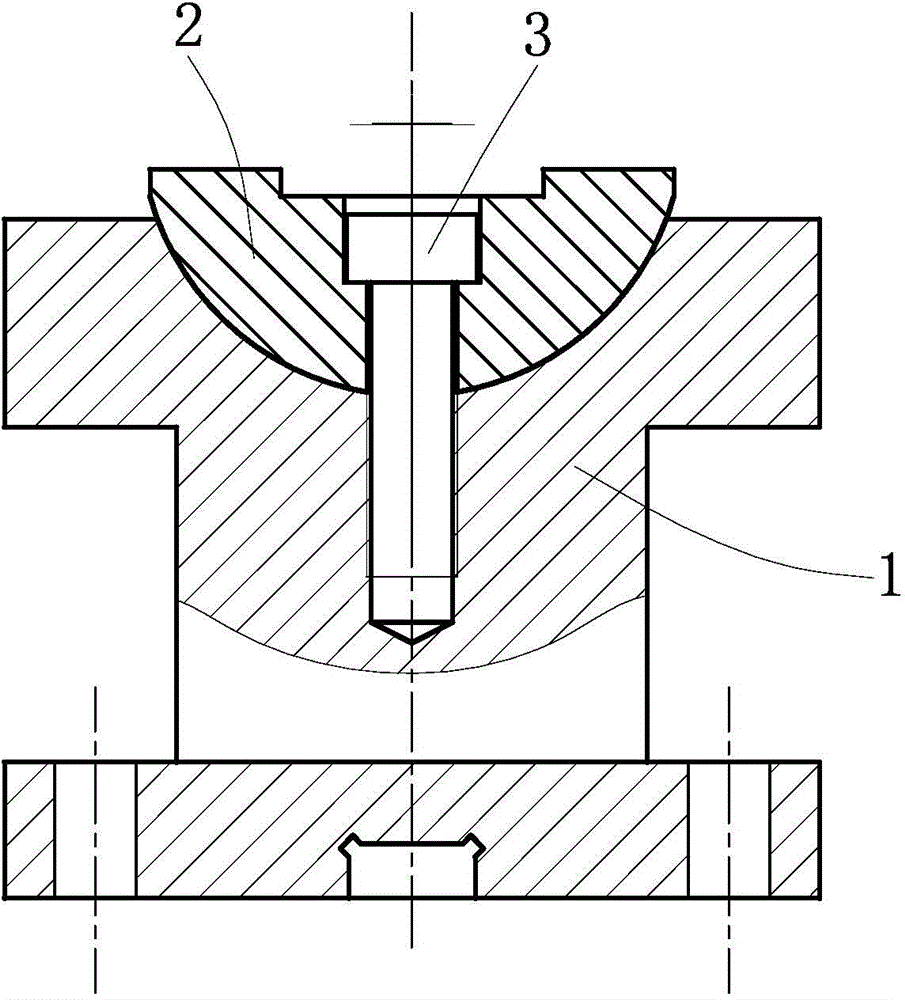

[0017] Such as figure 1 , figure 2 As shown, a floating contour pad assembly for a vertical drilling machine is mainly composed of three parts: contour pad 1, floating block 2, and countersunk screw 3.

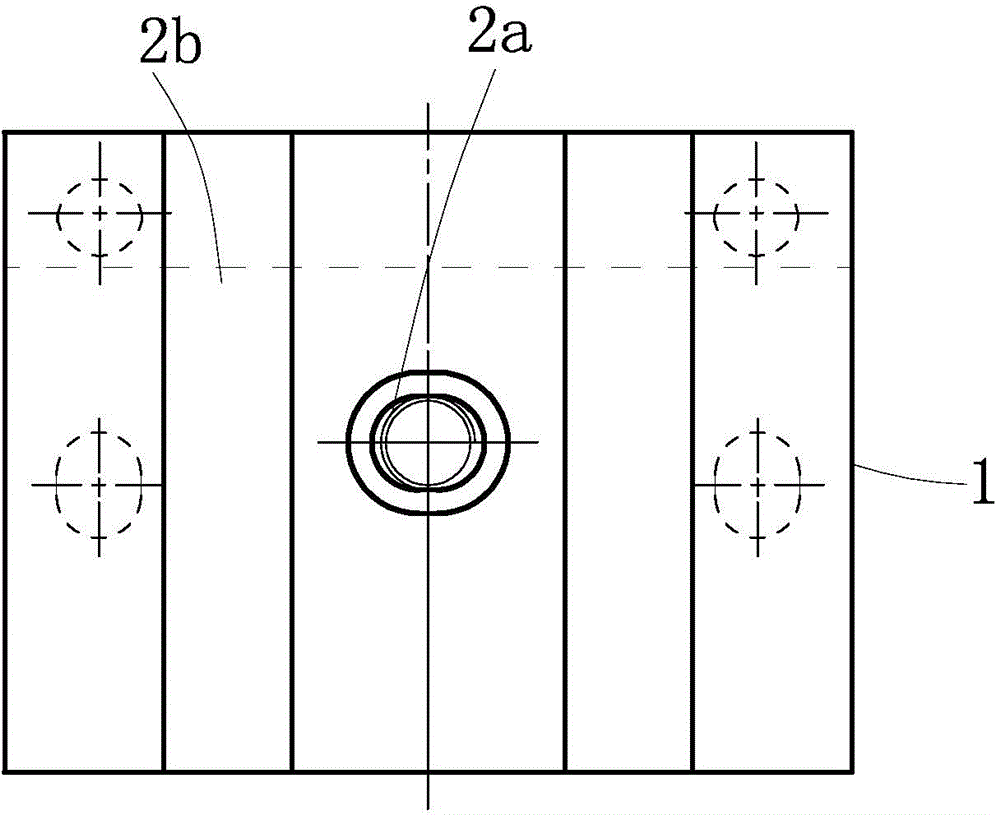

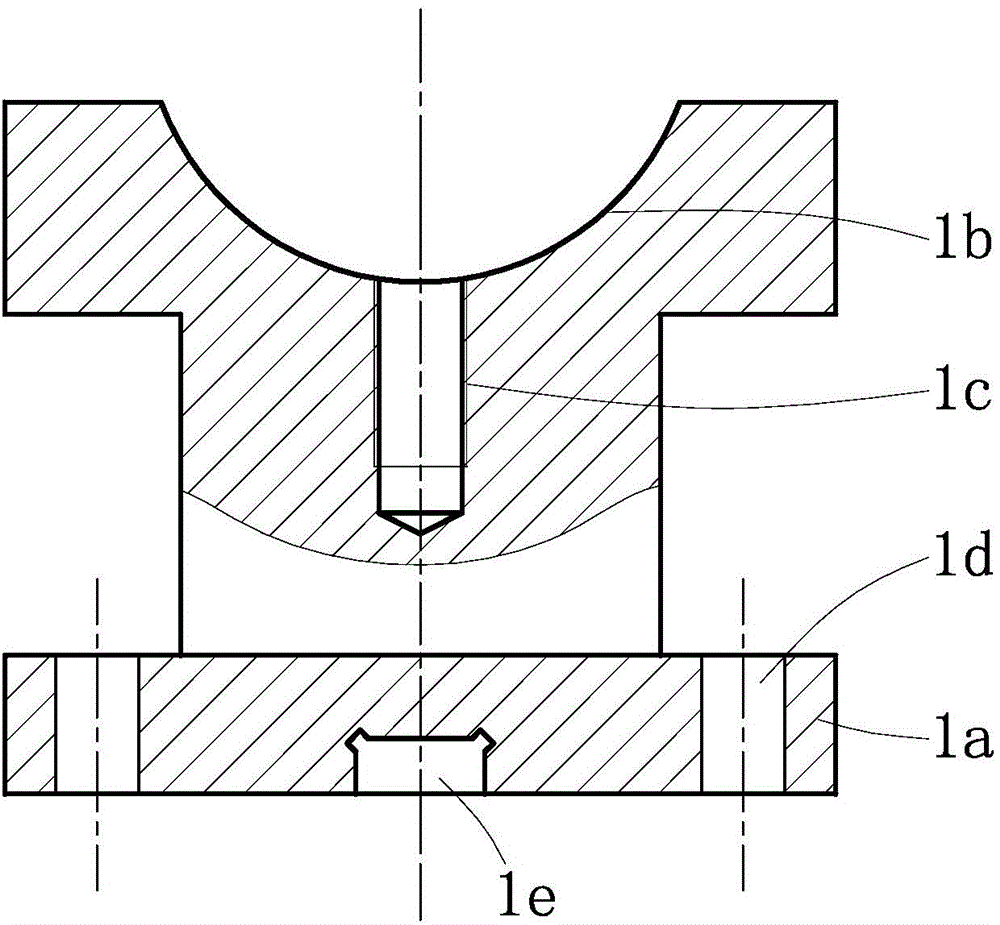

[0018] Combine figure 1 —— Image 6 As shown, the bottom of the contour pad 1 is provided with a mounting seat 1a, and a mounting hole 1d is provided on the mounting seat 1a for connecting with the workbench of the vertical drilling machine. There are four mounting holes 1d in a rectangular arrangement, and three of the mounting holes 1d are waist-shaped holes. The bottom of the mounting seat 1a is provided with a positioning hole 1e matching the positioning column on the drilling machine table. The top of the contour pad 1 is provided with an arc-shaped groove 1b penetrating back and forth, and a threaded blind hole 1c extending downward is provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com