Production method of microbial fermented seaweed fertilizer

A microbial fermentation and production method technology, applied in the field of microbial fermentation seaweed fertilizer, can solve the problems of low production and use safety, damage to the active ingredients of seaweed, etc., to ensure the original ecological activity, avoid soil salinization, and improve the aggregate structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

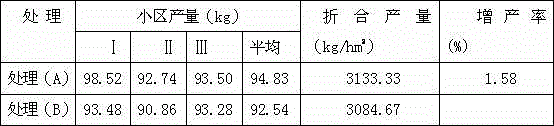

Image

Examples

Embodiment 1

[0029] (1) Wash and shred the dried seaweed into the reaction kettle for soaking. The amount of dried seaweed added is 10% of the water. Soak for 2 hours at a temperature of 25°C. The supernatant after soaking is passed through the ion exchange resin Filter to remove salt and heavy metals, and obtain solution A.

[0030] (2) Return solution A to the reaction kettle, add potassium citrate according to the weight ratio of dry seaweed: 0.6:100, soften and digest the seaweed at 25°C for 3 hours, after treatment, it will turn emerald green and dry A viscous liquid with a delicate smell was centrifuged to obtain seaweed slag and solution B.

[0031] (3) Add water to the seaweed residue to make the water content reach 40%, adjust the pH to 5.5, add a mixed strain of lactic acid bacteria and yeast with a weight ratio of 20:80, add molasses, yeast extract, and potassium dihydrogen phosphate , zinc sulfate heptahydrate, and ammonium bicarbonate mixed in a weight ratio of 100:7:2:2:2. ...

Embodiment 2

[0035] (1) Wash and shred the dried seaweed into the reaction kettle for soaking. The amount of dried seaweed added is 10% of the water. Soak for 4 hours at a temperature of 25°C. The supernatant after soaking is passed through the ion exchange resin. Filter to remove salt and heavy metals, and obtain solution A.

[0036] (2) Return solution A to the reaction kettle, add potassium oxalate in a weight ratio of 0.4:100 to dry seaweed, soften and digest the seaweed at 20°C for 4 hours, and get emerald green with a delicate fragrance after treatment Odor viscous liquid, seaweed slag and solution B were obtained by centrifugation.

[0037] (3) Add water to the seaweed residue to make the water content reach 45%, adjust the pH to 6.5, add the mixed strain of lactic acid bacteria and yeast according to the weight ratio of 30:70, and then add molasses, yeast paste, and dihydrogen phosphate A culture medium prepared by mixing potassium, zinc sulfate heptahydrate, and ammonium bicarbon...

Embodiment 3

[0041] (1) Wash and shred the dried seaweed into the reaction kettle for soaking. The amount of dried seaweed added is 40% of the water. Soak for 4 days at a temperature of 5°C. The supernatant after soaking is ion-exchanged Filter the resin to remove salt and heavy metals, and obtain solution A.

[0042] (2) Return solution A to the reaction kettle, add potassium pyrophosphate in a weight ratio of 2:100 to dry seaweed, soften and digest the seaweed at 40°C for 2 hours, and the treated clear liquid is emerald green It is a viscous liquid that is green and emits a delicate smell, and is centrifuged to obtain seaweed residue and solution B.

[0043] (3) Seaweed residue is supplemented with water to make the water content reach 40%, adjust the pH to 8.5, add a mixed strain of lactic acid bacteria and yeast with a weight ratio of 40:60, and then add molasses, yeast extract, potassium dihydrogen phosphate, The culture medium prepared by mixing zinc sulfate heptahydrate and ammoniu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap