Cigarette processing quality evaluation and diagnosis method

A process and quality evaluation technology, applied in the direction of instruments, electrical testing/monitoring, control/regulation systems, etc., can solve the problem that the overall quality of the process cannot be fully and truly reflected, the process has not been improved, and the overall fluctuation of the quality of cigarettes cannot be truly reflected, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

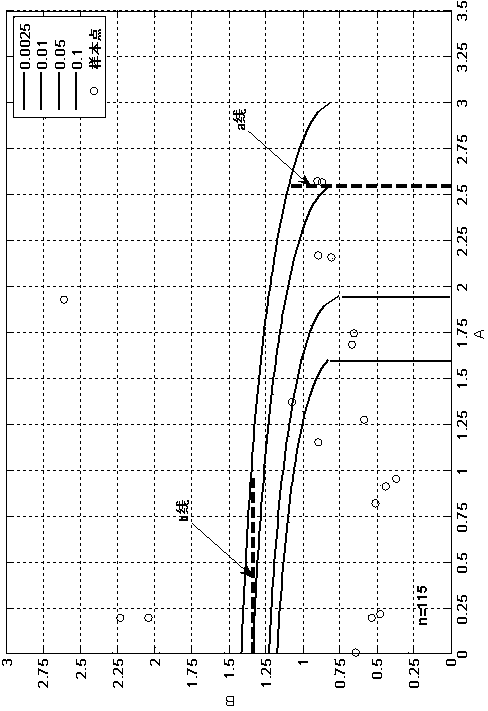

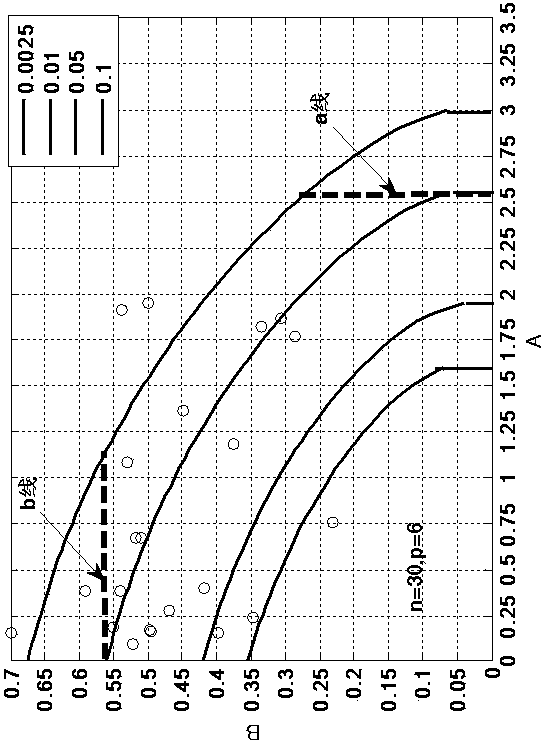

[0021] In order to make the technical problems to be solved by the present invention, technical solutions and beneficial effects clearer and clearer, the following examples and figure 1 , figure 2 , to further describe in detail the technical solution of the present invention. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0022] The method for evaluating and diagnosing the quality of the cigarette processing process of the present invention collects and processes historical data to construct a probability contour map of a sample, diagnose abnormal process parameters or indicators, and calculate the quality score. Specific steps are as follows:

[0023] Step 1, data collection and sample statistics calculation of silk production process

[0024] Taking silk production batches, grades, shifts, processes, etc. as retrieval elements, collect historical data that meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com