Pixel structure and manufacturing method of cmos image sensor

An image sensor, pixel structure technology, applied in semiconductor/solid-state device manufacturing, electrical components, radiation control devices, etc., can solve the problems of power consumption process, depletion layer width, small thickness, etc., to improve performance and reliability , expand the area, improve the effect of light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

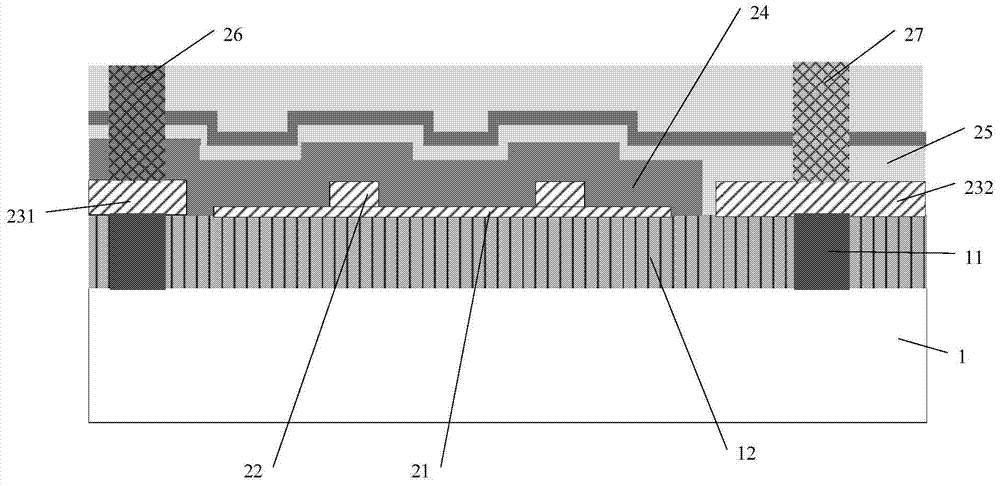

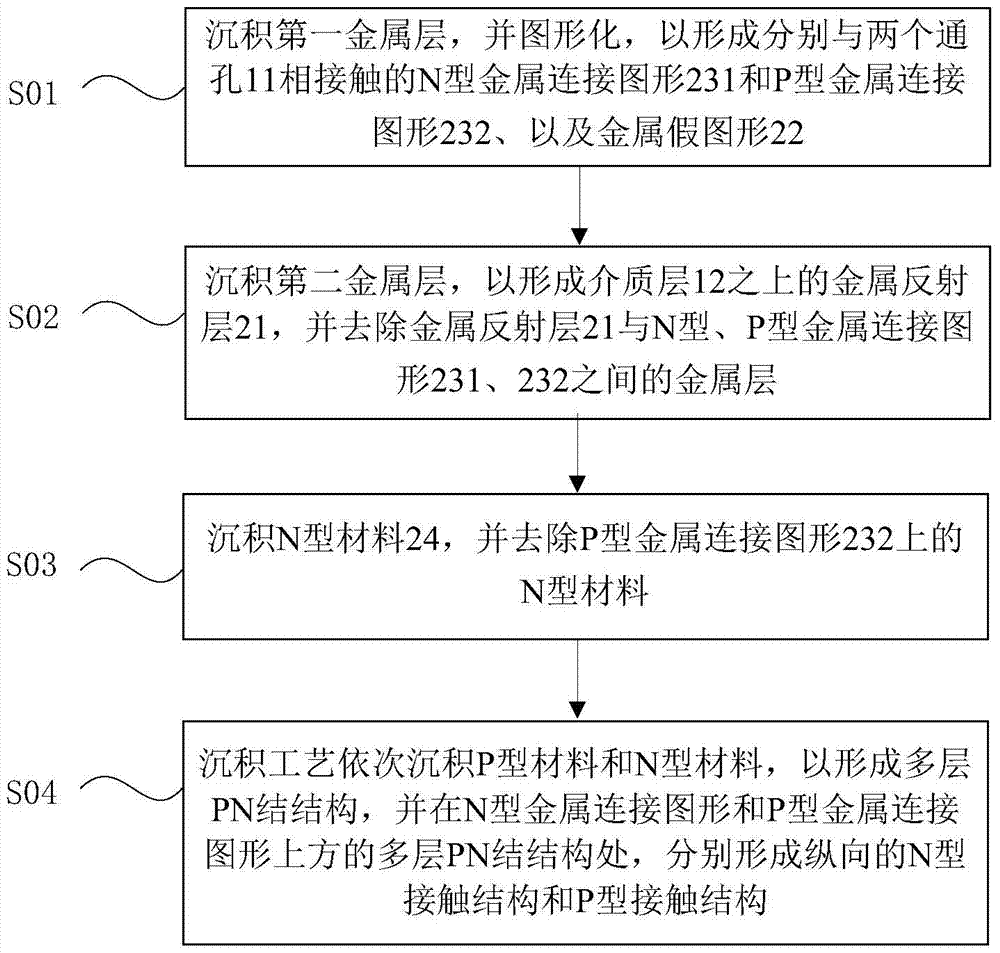

[0032] see figure 1 , the pixel structure of the CMOS image sensor of this embodiment, which is made on the top layer of the reading circuit 1, the top layer of the reading circuit 1 includes a dielectric layer 12 and a through hole 11 on both sides of the dielectric layer 12, the pixel Structures include:

[0033] The metal reflective layer 21 is located on the dielectric layer 12;

[0034] The metal dummy pattern 22 is located on the metal reflective layer 21;

[0035] Metal connection patterns, including N-type metal connection patterns 231 and P-type metal connection patterns 232 respectively located on the two through holes 11;

[0036] A multi-layer PN junction structure, where P-type material 25 and N-type material 24 are staggered and superimposed on the metal reflective layer 21, the metal dummy pattern 22 and the metal connection pattern;

[0037] The contact structure includes a vertical N-type contact structure 26 located on the N-type metal connection pattern 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com