Optoelectronic module and method for producing an optoelectronic module

An optoelectronic module, conductivity technology, applied in circuits, electrical components, electrical solid devices, etc., can solve problems such as unfavorable arrangement of multiple semiconductor chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

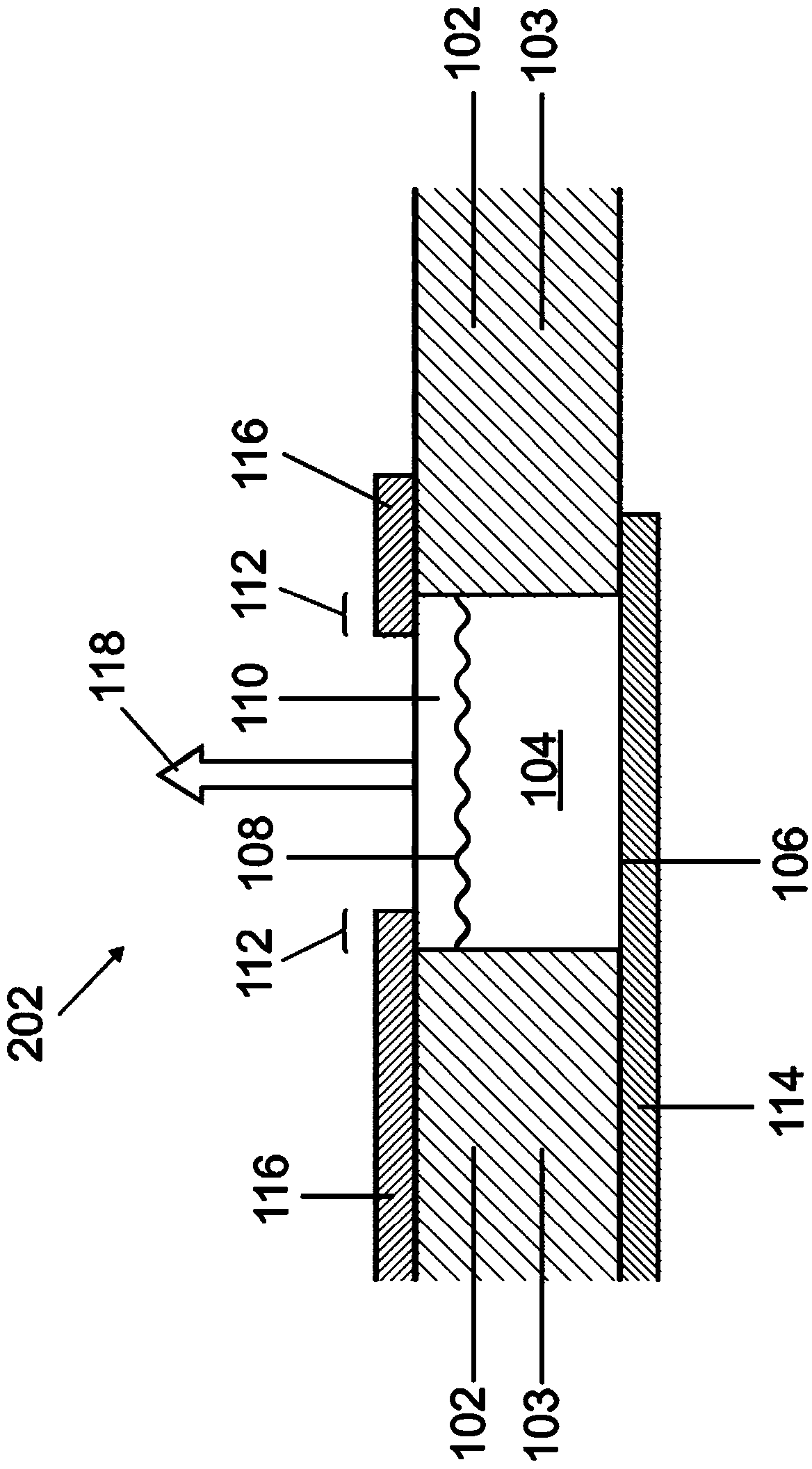

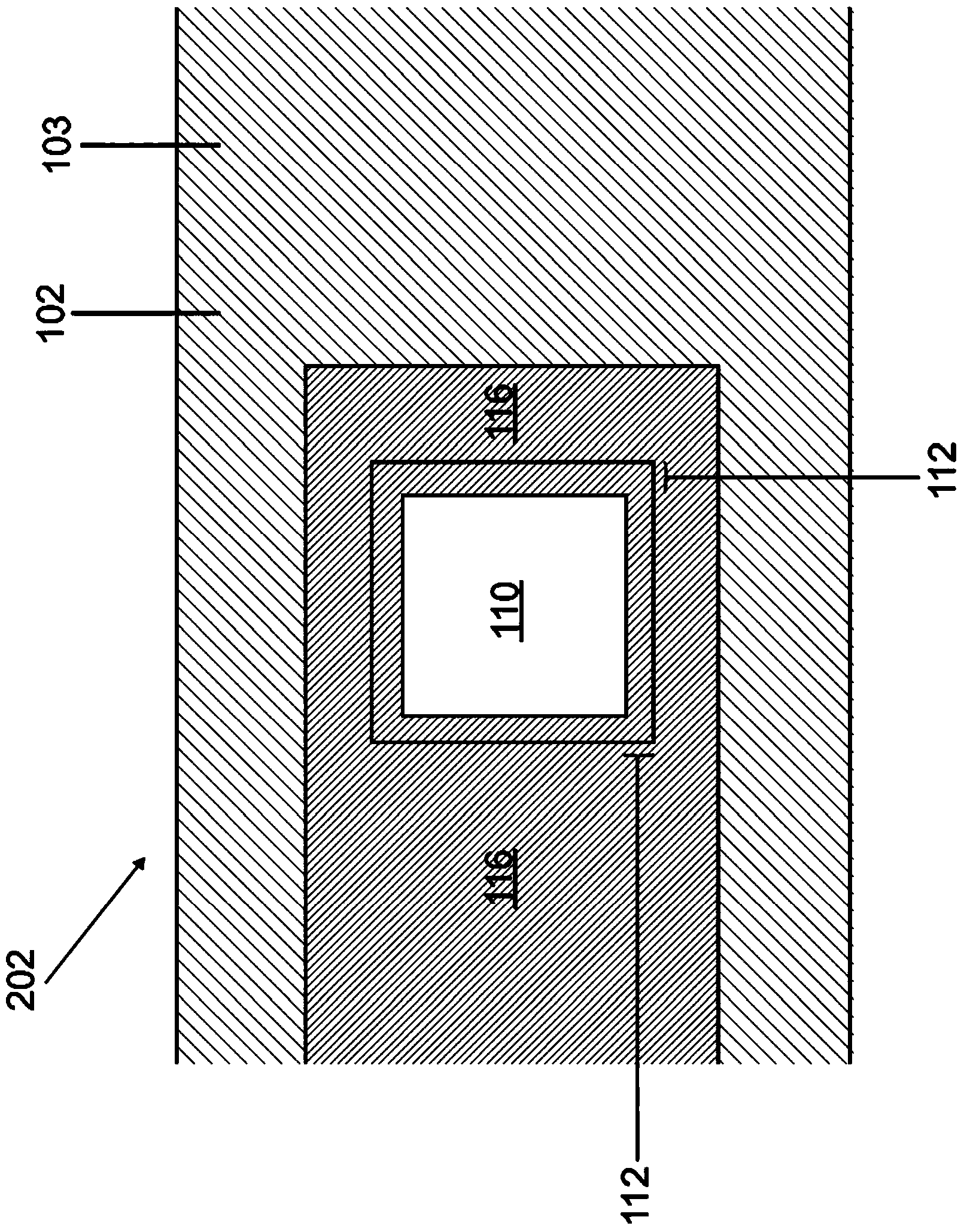

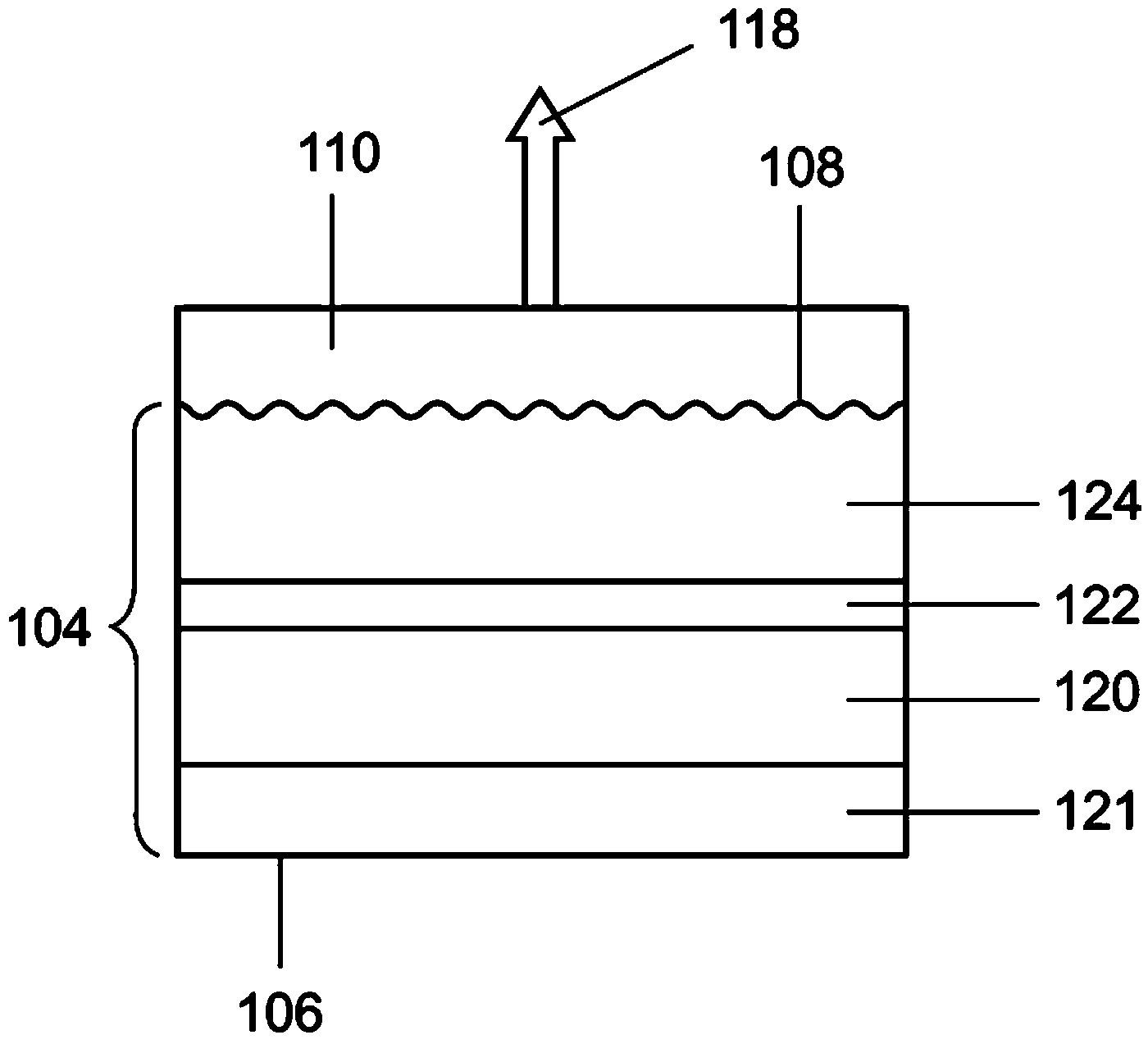

[0134] Figure 1a A sectional view of a first exemplary embodiment of an optoelectronic module 202 according to the invention is shown. Module 202 has a semiconductor chip 104 for emitting electromagnetic radiation 118 . The semiconductor chip 104 has a plurality of epitaxial layer sequences (in Figure 1a not shown, see figure 2 and 3). The semiconductor chip has an emission surface 108 , which is defined as the surface of the epitaxial layer on which electromagnetic radiation 118 emerges from the semiconductor chip 104 . Radiation surface 108 has outcoupling structures (shown as corrugated lines) which increase the efficiency with which electromagnetic radiation 118 is coupled out of semiconductor chip 104 via radiation surface 108 . A first contact, which is formed as a transparent contact layer 110 , is arranged on the emission surface 108 . Transparent currently means that electromagnetic radiation in the visible spectral range passes through the contact layer 110 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com