Fertilizing, sowing and weeding device of tillage machine

A cultivator and rotary tiller technology, which is applied to devices for catching or killing insects, sowing seeders, agricultural machinery and implements, etc., can solve the problems of uneven sowing, waste of manpower, and inability to purchase, so as to achieve uniform sowing, Strong practicality and uniform rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

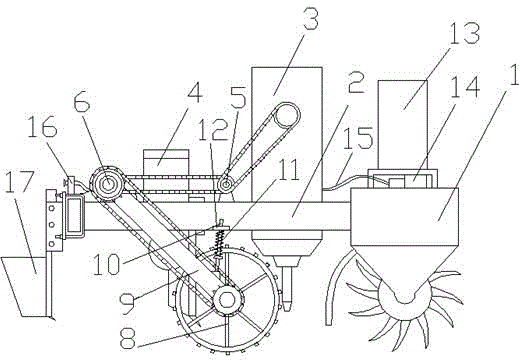

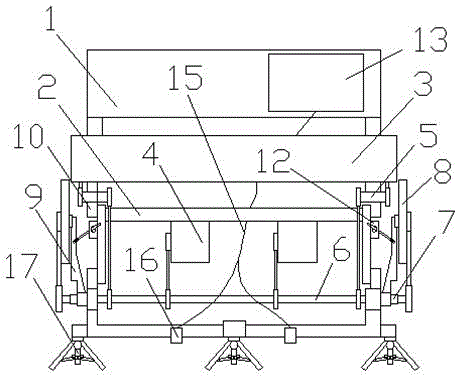

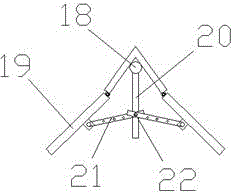

[0015] Such as figure 1 , 2 The fertilization, seeding and weeding device of a kind of cultivator shown in . 8. Connecting rod 9, movable rod 10, spring 11, fixed plate 12, liquid medicine tank 13, water pump 14, water pipe 15, nozzle 16, ridging device 17, the frame 2 is fixed on the rotary cultivator 1 by screws and on the same level as the rotary tiller 1, the fertilizer 3 is fixed on the front of the frame 1, the seeder 4 is fixed on the middle of the frame 2, and the transmission gear set 5 passes through the bearing Fixed in the middle of the frame 2, and connected with the fertilizer applicator 3 through a chain, the transmission shaft 6 is fixed in the rear of the frame 2 through the bearing sleeve 7, and connected with the seeder 4 and the transmission gear set 5 through the chain respectively , one end of the connecting rod 9 is welded with a metal ring, sleeved on the bearing sleeve 7, and the other end is equipped with a power wheel 8, the power wheel 8 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com