Bundle tube type water bed reactor

A beam-tube, reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of easy leakage, uneven gas distribution, low heat transfer efficiency, etc., to ensure reliability and improve effective utilization. The effect of uniform gas distribution rate and gas distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

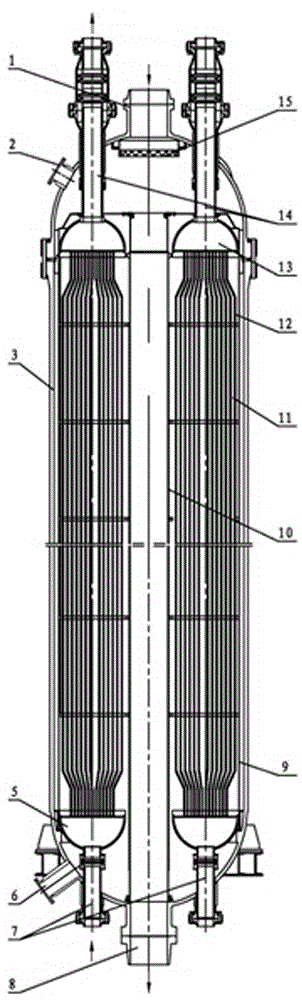

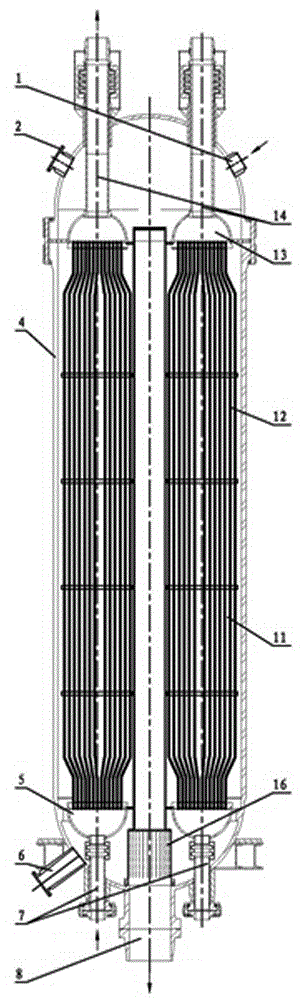

[0020] Further illustrate the present invention below in conjunction with accompanying drawing.

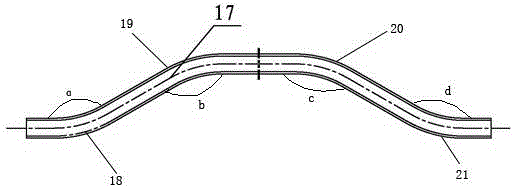

[0021] see figure 1 with image 3 , when the reactant gas flows radially, the bundled tube water bed reactor includes a radial flow shell 3, and the top of the radial flow shell 3 is provided with a synthesis gas inlet 1, a circulating water outlet 14 and a manhole 2, The radial flow shell 3 is provided with a synthesis gas outlet 8, a circulating water inlet 7 and a catalyst self-unloading port 6; the radial flow shell 3 is provided with a water-cooled bundle tube assembly 12, a gas distributor 15, and a gas radial distribution cylinder 9 and gas radial gas collection cylinder 10; the gas distributor 15 is arranged at the synthesis gas inlet 1, and the gas radial distribution cylinder 9 and the gas radial gas collection cylinder 10 are arranged between the gas distributor 15 and the synthesis gas outlet 8, The gas radial distribution cylinder 9 and the gas radial gas collection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com