Sand washing machine with fine sand recovering and rewashing function and obtaining method thereof

A sand washing machine and fine sand technology, which is applied in the field of sand washing machines, can solve the problems that fine sand cannot be recycled and washed again, and achieve the effects of reducing pollution pressure, convenient production and matching, and convenient combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

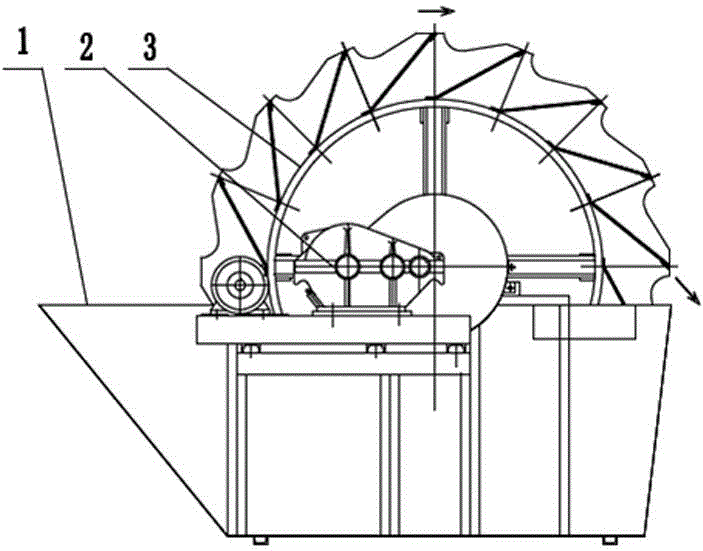

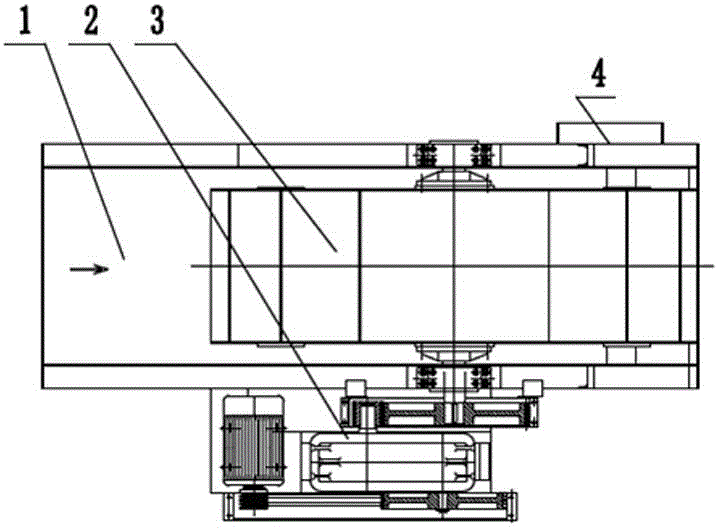

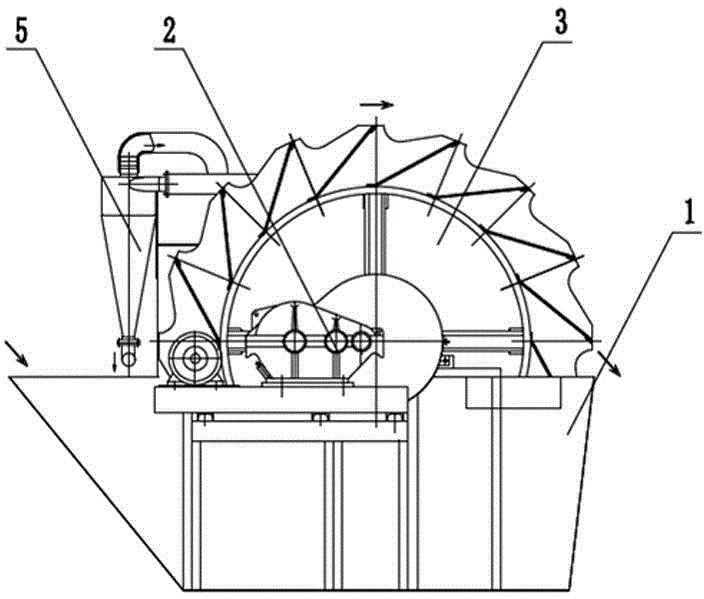

[0035] Example: such as image 3 and Figure 4 As shown, it is a φ2600×800 bucket wheel sand washing machine with fine sand recovery function, including a settling tank 1, power system 2, bucket wheel 3, drain port 4, hydrocyclone 5, clear water drainage Port 6, water diversion tank 7, diverter valve 8, sewage pump 9, water collection tank 10, conduit pipeline, etc. Grit sink 1, power system 2, bucket wheel 3, and drain 4 form a bucket wheel sand washing machine, hydrocyclone 5, clean water drain 6, water diversion tank 7, diverter valve 8, sewage pump 9, water collection tank 10 The fine sand recovery system is composed of conduits and pipelines. The fine sand recovery system is integrated with the bucket wheel sand washing machine through the integral connection structure of the water collection tank 10 and the grit chamber 1 .

[0036] like Figure 7 As shown, the hydrocyclone 5 includes a swirl casing, and the swirl casing has a separation chamber formed by connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com