Product mixed sorting method and sorting time calculating method

A time calculation and product technology, applied in sorting and other directions, can solve the problem of waiting time affecting the picking efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

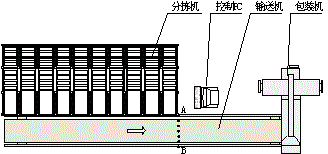

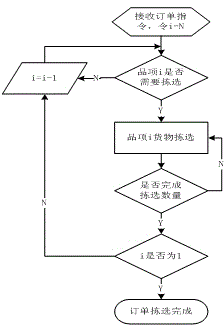

Image

Examples

Embodiment Construction

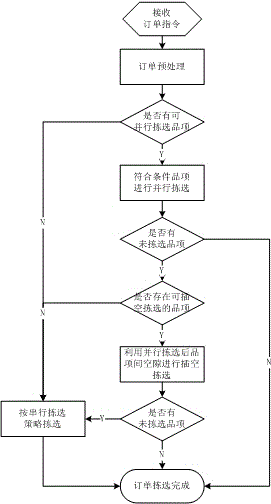

[0021] A hybrid picking strategy combining series and parallel. Such as image 3 As shown in Fig. 1, when the picking operation is carried out with a single-order serial-parallel mixed picking strategy, the received order is firstly preprocessed to determine whether the order can be partially or completely parallel picked. strategy selection. For some orders that are picked in parallel, it is judged whether there is a gap between the picked items on the conveying system. If there is a gap, select the item that can be picked by using the gap among the unpicked items for interstitial picking. For the last remaining unpicked items, pick according to the serial picking strategy. After all the items required by the order have been picked and ejected and conveyed out of the picking area, the next order starts to be picked.

[0022] Let the total number of batches of orders be M, the total number of items contained in the batch of orders be N, and the number of pickers equal to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com