Defogging and defrosting device for locomotive front windshield glass

A front windshield and motor vehicle technology, applied in the field of auto parts, can solve the problems of easy misalignment of connections, affecting the effect of air conditioning, and easy deformation of air ducts, so as to achieve convenient and quick installation and disassembly, improve reliability, and increase working speed and the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings.

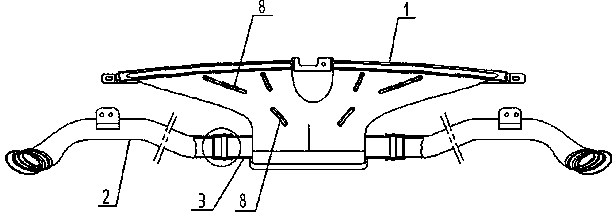

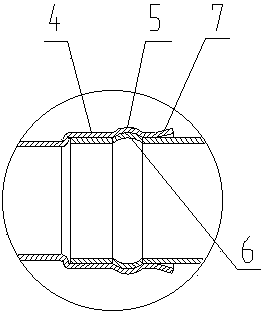

[0015] Such as figure 1 and figure 2 As shown, the motor vehicle front windshield defogging and defrosting device in this specific embodiment includes a central air duct 1 and ventilation ducts 2 located on both sides of the central air duct 1, and the two sides of the central air duct 1 respectively include air guides. Pipe 3, the air guiding pipe 3 communicates with the ventilation pipe 2, the ventilation pipe 2 includes an elastic connecting pipe 4 for being inserted into the air guiding pipe 2, the pipe wall of the elastic connecting pipe 4 is provided with Outward annular protrusion I5 along the circumferential direction, the pipe wall of the air guide pipe 2 is provided with an annular protrusion II6 matching the inner surface of the annular protrusion I5, the central air duct 1 and the ventilation duct 2 are respectively provided with connecting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com