Pneumatic monorail crane

A monorail crane and track technology, which is applied to the track system, load block, load suspension components, etc., can solve problems affecting the health of miners, on-site environmental pollution, and high labor intensity, so as to improve the level of roadway operations and enhance safety , the effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

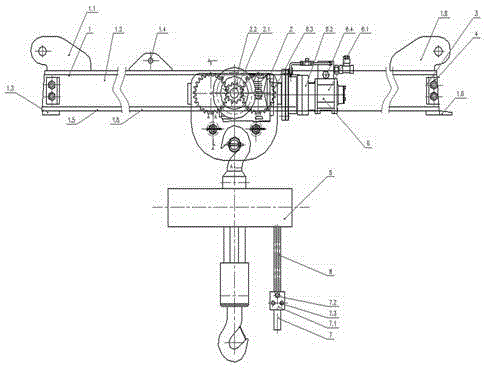

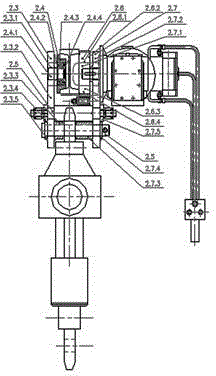

[0020] Embodiments of the present invention are further elaborated below in conjunction with accompanying drawings:

[0021] The pneumatic monorail crane of the present invention includes a track arranged in the middle of the top of the roadway, a running mechanism that travels on the track, and a lifting mechanism driven by the running mechanism. Composed of traveling drive device 6, spacers 3 and stoppers 4 are fixed at both ends of the track, lifting mechanism 5 is fixed below the traveling vehicle assembly 2 through a pin shaft, and traveling driving device 6 is connected by a flange and fixed on the walking track On one side of the car assembly 2, the manual valve 7 controls the walking and lifting of the traveling mechanism and the lifting mechanism 5 through the rubber hose 8; the rubber hose 8 is connected between the pneumatic reversing valve 6.4 and the manual valve 7 through a quick plug;

[0022] The track assembly 1 as the main frame is composed of a doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com