Mix proportion design method for constant-temperature modified asphalt mixture

A technology of room temperature modified asphalt and mix ratio design, which can be applied to cohesive pavement paved on site, roads, roads, etc. It can solve problems such as difficulty in finding the asphalt ratio, lack of a complete technical system, and failure to meet design requirements. To achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

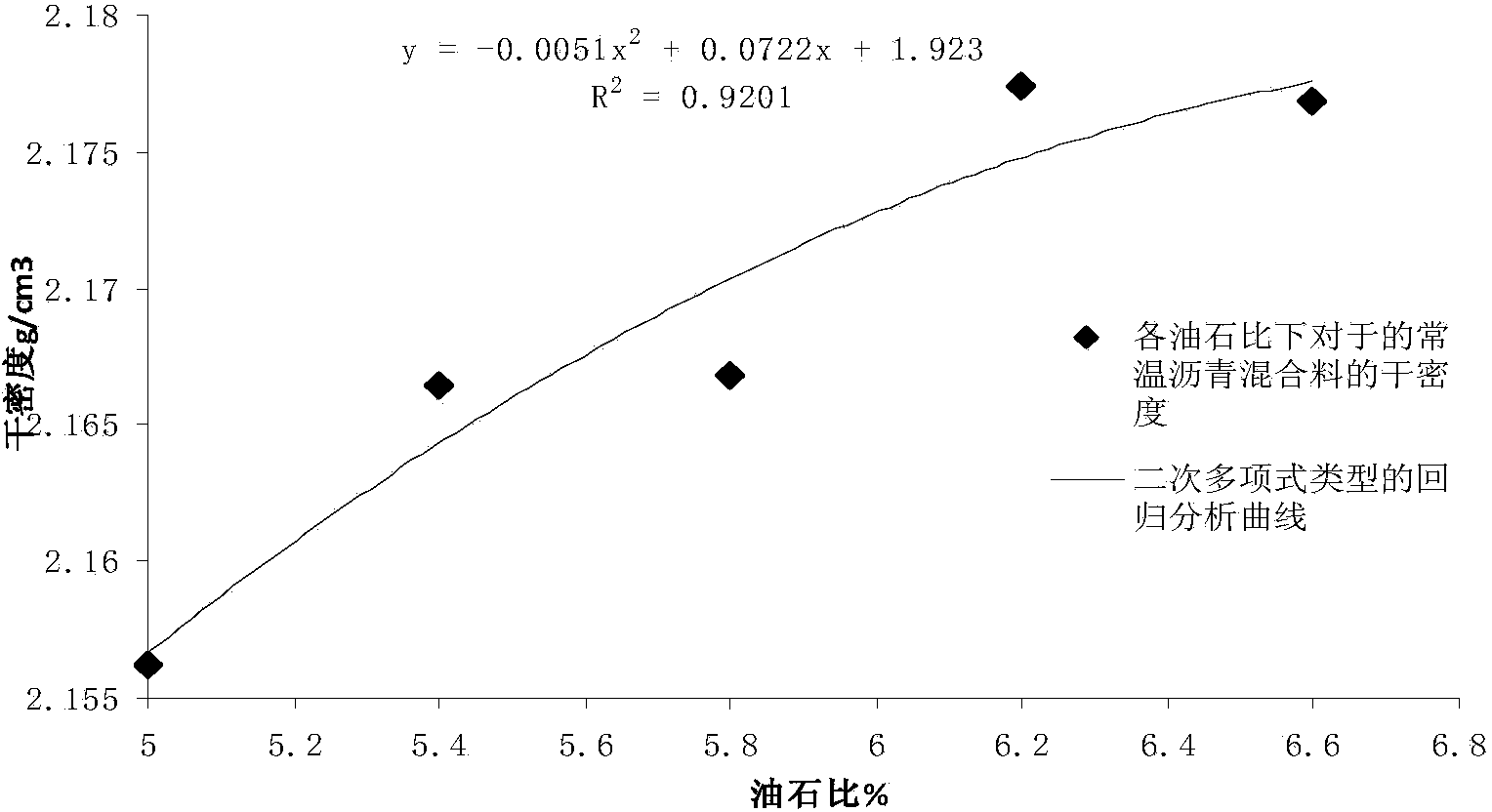

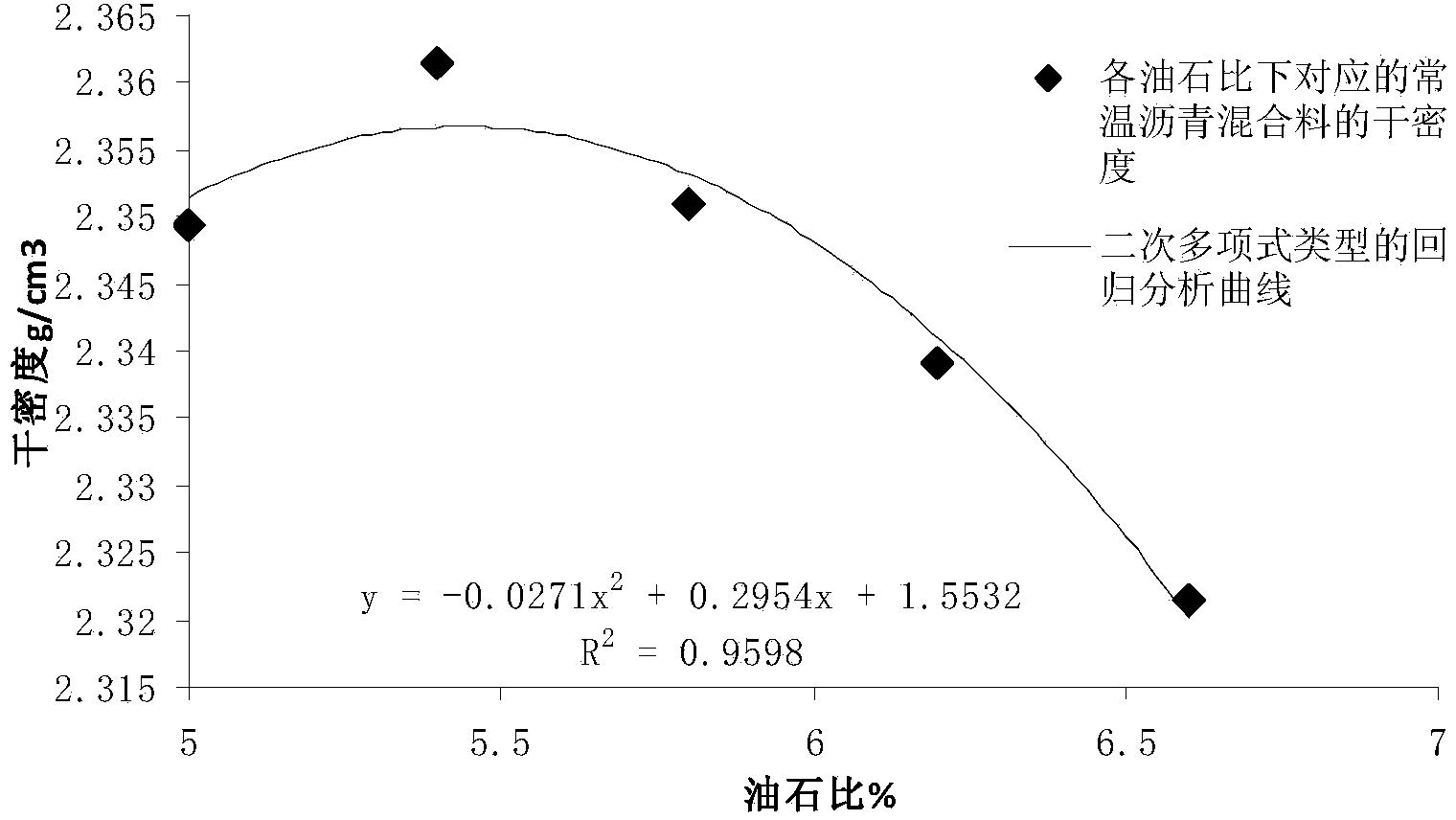

[0017] In the following of the present invention, a specific embodiment—the embodiment of SAC-10 normal temperature modified asphalt mixture is given to illustrate the present invention in more detail.

[0018] 1. Grading of raw materials and minerals

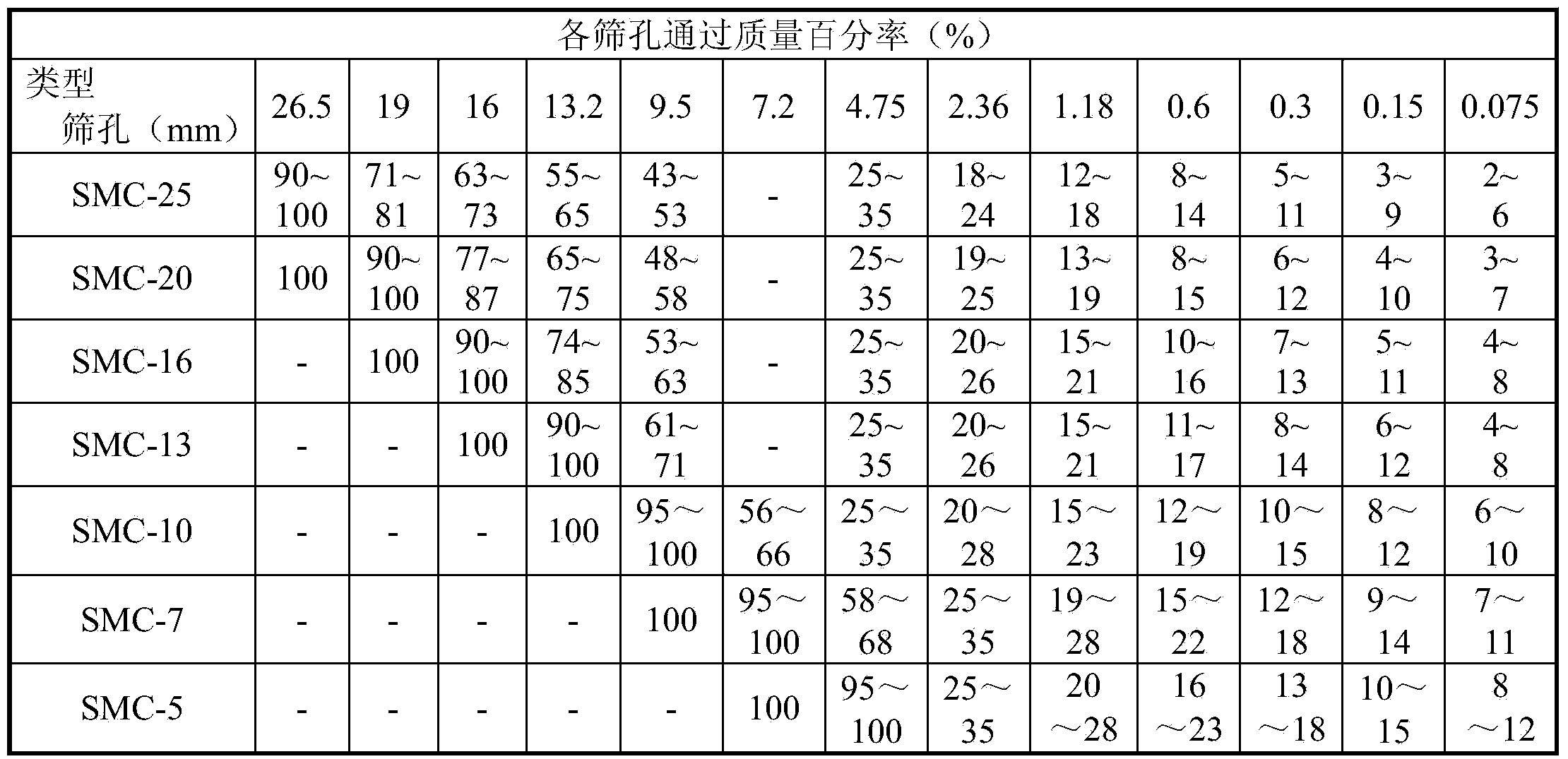

[0019] Selecting the appropriate mineral aggregate gradation is the key to the successful application of normal temperature modified asphalt mixture, and it is also an important factor affecting the evaluation of its road performance. The room temperature modified asphalt mixture adopts discontinuous gradation, and is divided into 7 types according to the nominal maximum particle size: 5 types, 7 types, 10 types, 13 types, 16 types, 20 types and 25 types, and their code names are: SMC-5, SMC-7, SMC-10, SMC-13, SMC-16, SMC-20, SMC-25. Grading types and their reference ranges are shown in Table 1 below:

[0020] Table 1: Mineral gradation types and reference ranges of normal temperature modified asphalt mixture

[0021]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com