Pouring device and construction method of grouted wall

A construction method and wall technology, applied in the processing of building materials, construction, building construction, etc., to achieve the effect of improving quality standards and improving technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

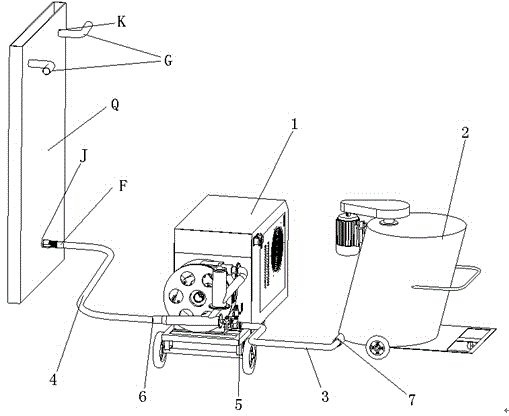

[0028] A reference to pouring equipment for a grouted wall in this embodiment figure 1 , including a cavity wall Q and a pumping machine 1 for pouring slurry into the cavity wall Q, the lower middle part of the cavity wall Q has a pouring hole J, and the upper part has an air guide hole K; The pumping machine 1 is connected to the pouring hole J through the slurry delivery pipe 4 and the valve body F. One end of the valve body F is connected to the pouring hole J of the cavity wall Q, and the other end is connected to the slurry delivery hole J. The pipe 4 is connected; the prepared slurry is transported by the pump 1 to the valve body F connected to the bottom of the cavity wall Q through the slurry delivery pipe 4, and the slurry is discharged to the valve body F through the valve body F. Inside the cavity wall Q; the air guide hole K above the cavity wall Q is connected with an air guide tube G; the pump 1 is also connected to a mixer 2, and the mixer 2 passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com