Connection device, rotor and installation method of semi-open impeller and main shaft of centrifugal compressor

A technology for centrifugal compressors and connecting devices, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, non-variable-capacity pumps, etc. It can improve the assembly process, shorten the assembly and disassembly time, and reduce the maintenance cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

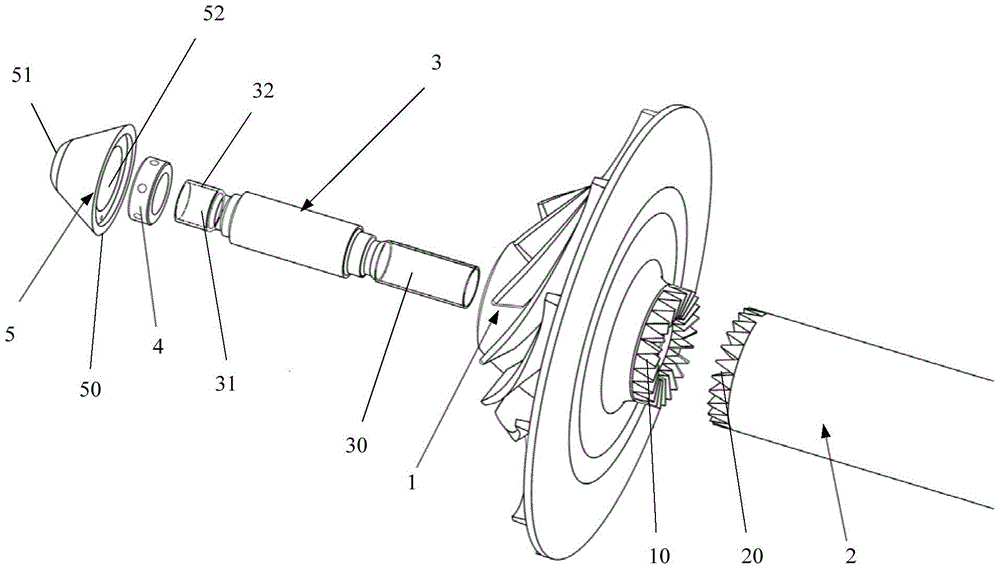

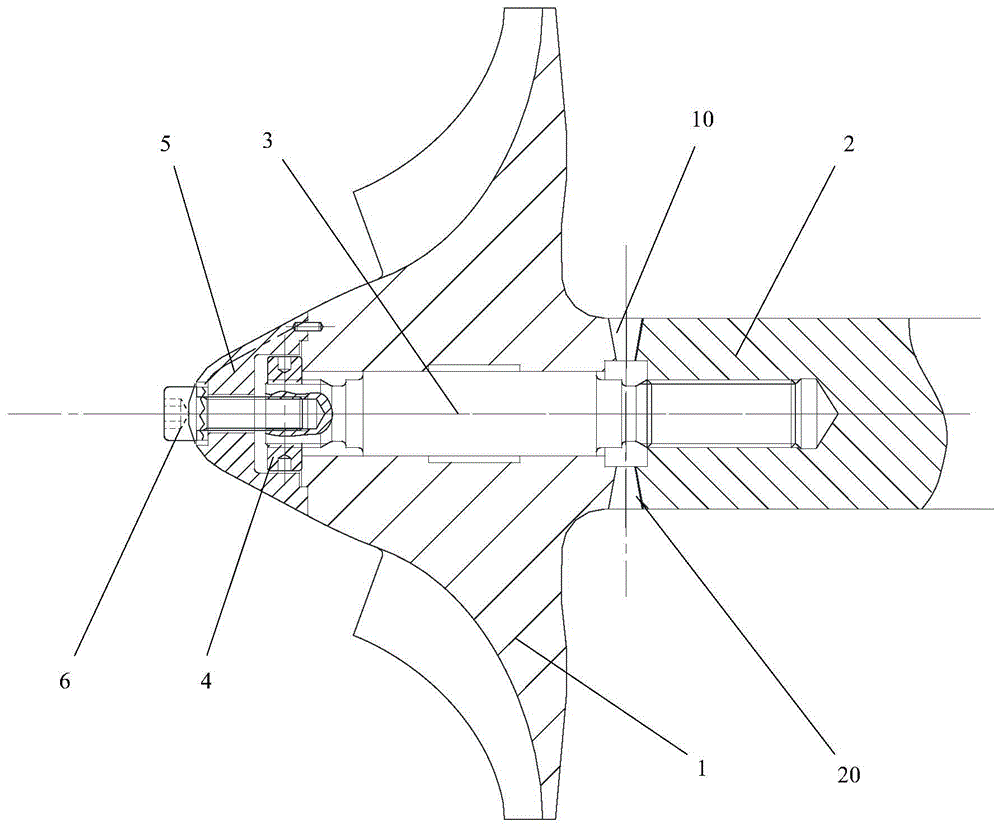

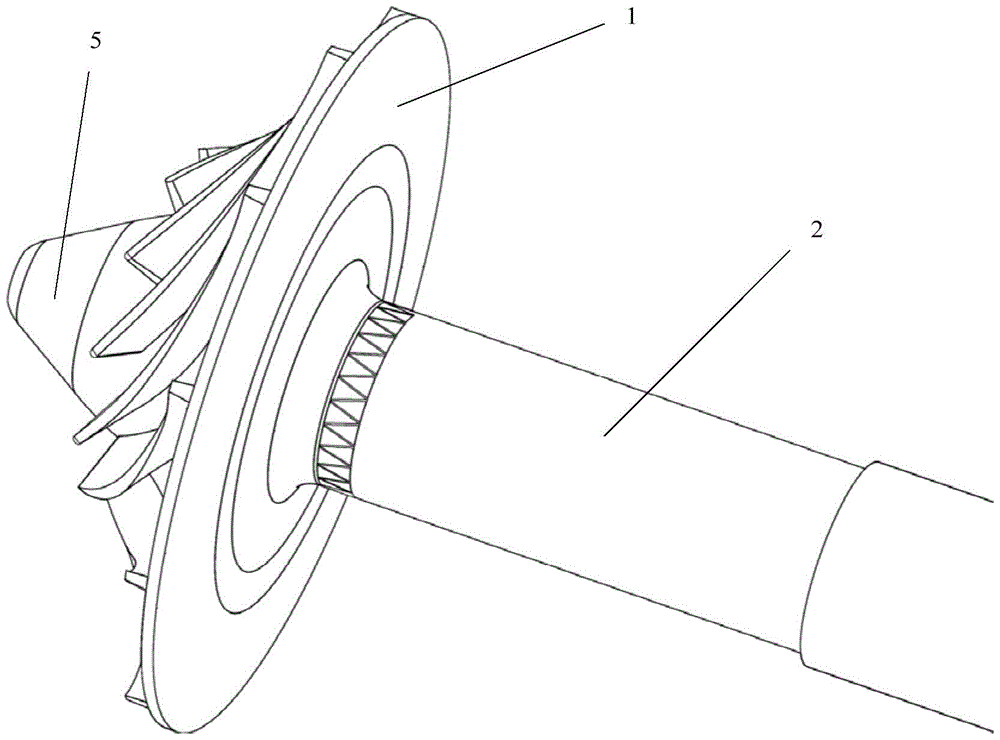

[0027] like Figure 1 ~ Figure 4 The shown connection device between the semi-open impeller and the main shaft of the centrifugal compressor includes: the end face tooth I10 arranged on the end face of the hub of the semi-open impeller 1 without blades, the end face tooth II20 arranged at one end of the main shaft 2, the connecting stud 3 and The lock nut 4; the end tooth I10 and the end tooth II20 are matched and meshed; the semi-open impeller 1 has a central hole, and the diameter of the central hole is greater than or equal to the diameter of the connecting stud 3; one end of the main shaft 2 with the end tooth II20 is provided with The first threaded hole 21, and the first threaded hole 21 is arranged along the central axis of the main shaft 2; the two ends of the connecting stud 3 have a first screw part 30 and a second screw part 31 respectively; the connecting stud 3 passes through the central hole, the first The screw part 30 is matched and screwed with the first threa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com