Refrigerant leakage protection control method for multi-split air conditioners

A protection control and air conditioner technology, which is applied in the direction of control input involving air characteristics, space heating and ventilation control input, heating and ventilation control system, etc., which can solve the problem of increased unit maintenance costs, leakage of other modules of refrigerant, failure to operate normally Work and other issues, to avoid increased maintenance costs, reasonable process, and improve application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

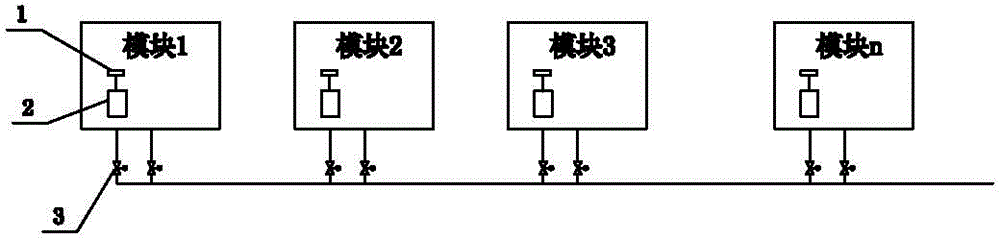

[0022] As shown in the figure, the multi-connected air conditioner includes multiple modules with the same structure and function. Each module communicates with a common transmission pipeline through a solenoid valve 3 . A refrigerant leakage detection sensor 1 is installed in each module, and the sensor is connected with a controller 2 in the module. Related control parameters such as detection frequency T1, refrigerant leakage amount P, leakage duration T, and repeated leakage times N are preset in the controller. Control method of the present invention comprises the following steps:

[0023] a. After the machine is running, each module will self-check whether there is any refrigerant leakage at the detection frequency T1;

[0024] b. If a module is detected to be leaking, close the solenoid valve connecting the module to the public pipeline;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com