Integrated checking fixture

A technology of comprehensive inspection tools and inspection tools, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., can solve the problems of low detection efficiency of bottom plate products, and achieve the effects of easy confirmation and sorting, convenient inspection tool management, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

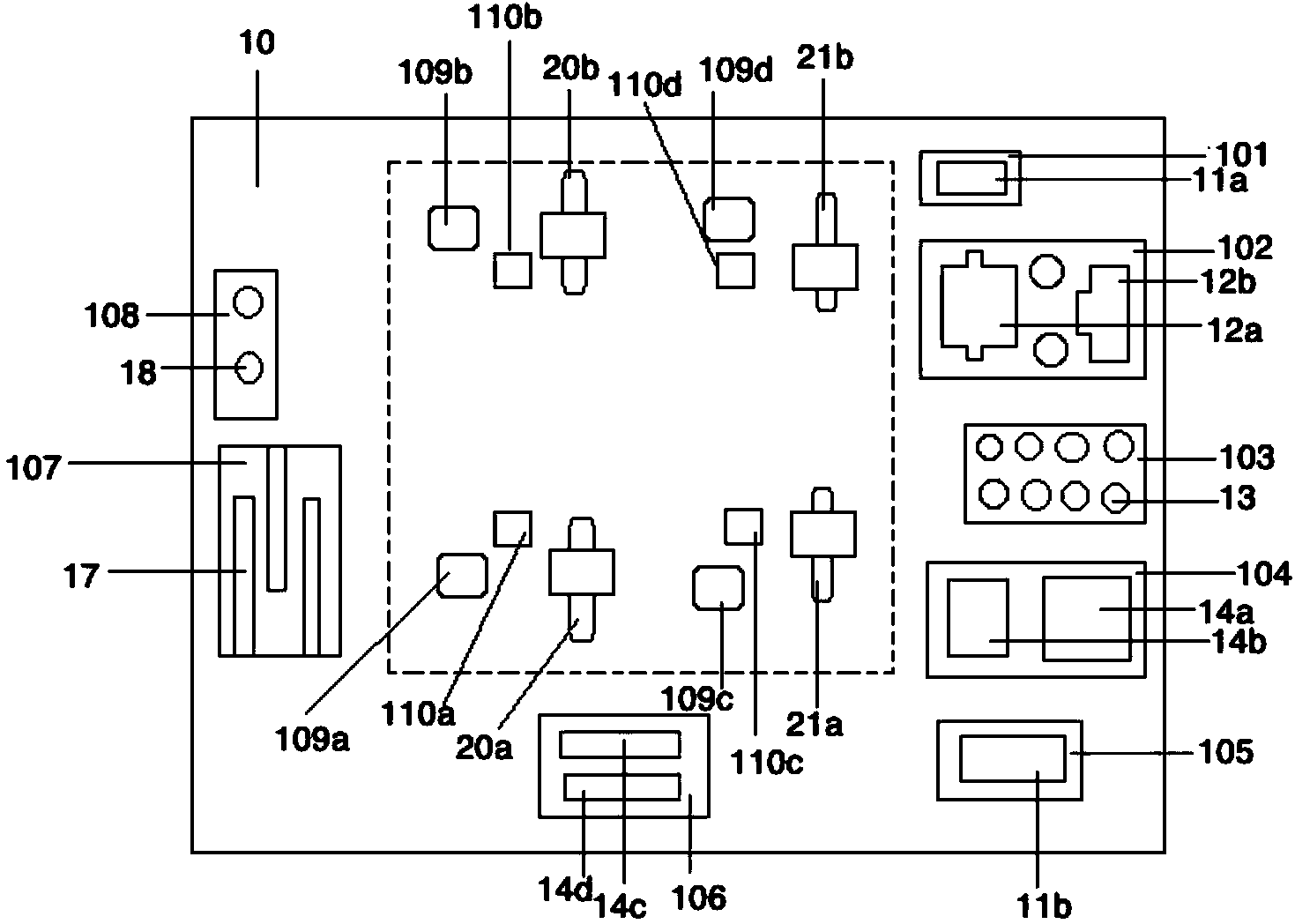

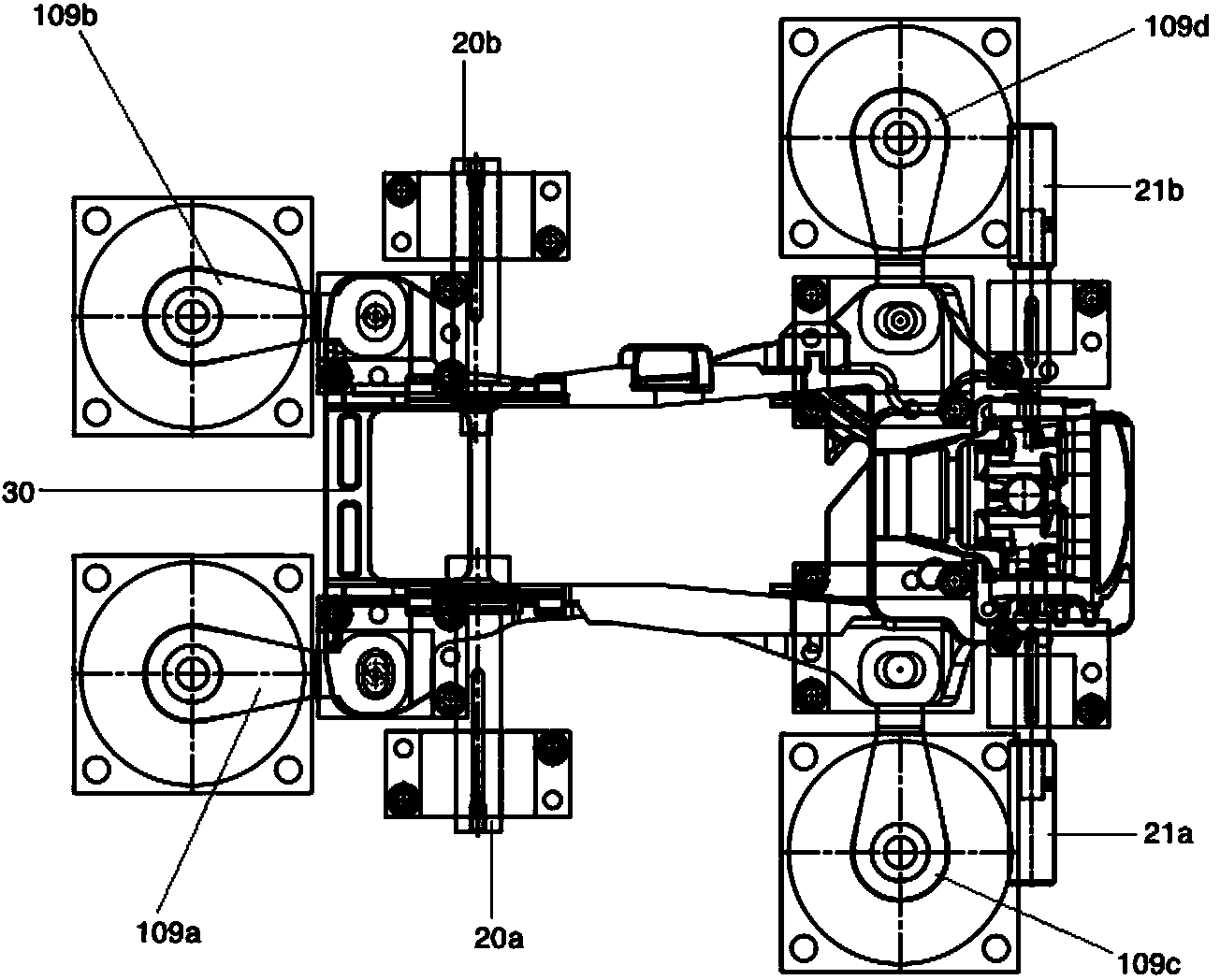

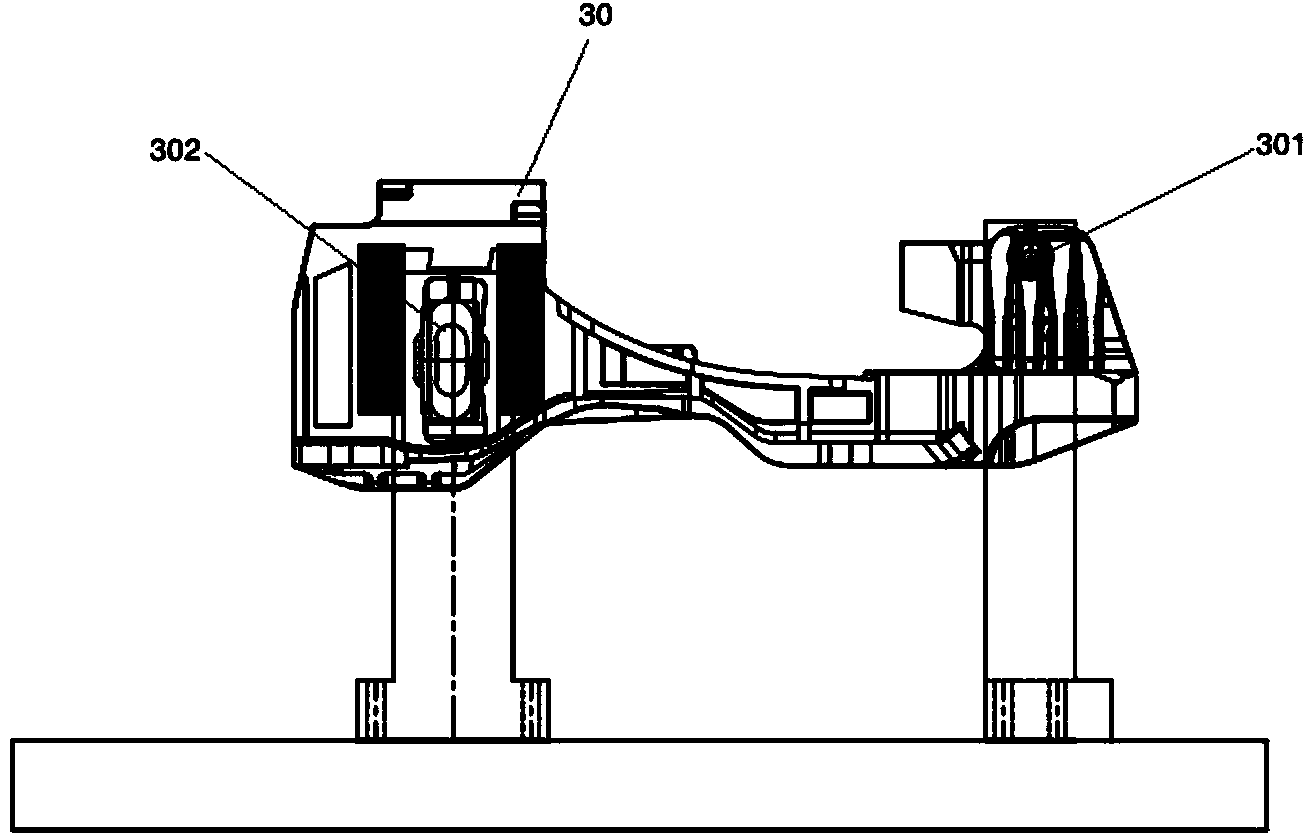

[0016] Please also refer to figure 1 to Fig. Such as figure 1 As shown, the comprehensive inspection tool provided by the present invention includes a base 10 . A plurality of protrusions 101-108 are arranged on the base 10, and a plurality of receiving grooves of different shapes and sizes are respectively arranged on the plurality of protrusions 101-108. Herein, the shape of the accommodating groove is described by the shape of the groove in a horizontal section. exist figure 1 , the base 10 can be divided into a middle area (that is, the area marked with a dotted line) and a peripheral area, and the middle area is a product assembly simulation area here. Five bumps 101 - 105 are arranged in sequence from top to bottom in the right peripheral area. Wherein, the rectangular receiving groove of the protruding block 101 is provided with a slot width go-no-stop gauge 11a, and the irregularly shaped receiving groove of the protruding block 102 is respectively provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com