Gas-liquid separating type multiphase flowmeter

A multi-phase flowmeter and gas-liquid separation technology, which is applied in the direction of liquid/fluid solid measurement, volume flow measurement device, measurement device, etc., can solve the problems of discouraging the use of radiation, poor measurement accuracy of water content, and complex structure, etc., to achieve Easy to use and operate, high measurement accuracy, and the effect of measuring environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

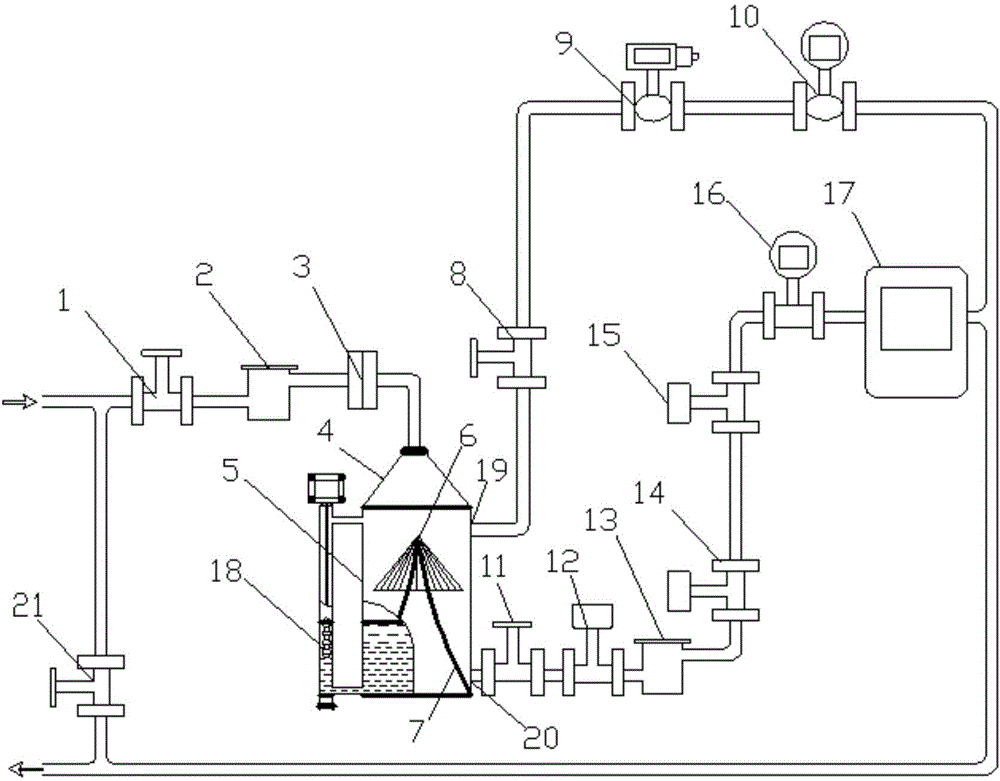

[0010] The main structure of the multiphase flowmeter involved in this embodiment includes: a first valve 1, a first heater 2, a flange 3, an oil-gas-water three-phase separator upper cover 4, an oil-gas-water three-phase separator 5, and a swirl plate tower 6. Swirl plate tower support 7, second valve 8, pressure transmitter 9, gas flow meter 10, third valve 11, first temperature sensor 12, second heater 13, second temperature sensor 14, third Temperature sensor 15, liquid flow meter 16, electronic display instrument 17, crude oil level gauge 18, gas phase outlet 19, liquid phase outlet 20 and fourth valve 21, all components are assembled and connected by pipelines to form an integrated gas-liquid separation type multi-phase flowmeter; the upper end of the oil-gas-water three-phase separator 5 with a swirling plate cylindrical structure is connected with the gas measuring pipeline through the flange 3, the first heater 2, the first valve 1, and the oil-gas-water three-phase se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com