A mechanical dynamic tester and test method for joint structure of flexible anti-seepage body

A dynamic test and impermeable body technology, applied in the direction of using stable tension/pressure to test the strength of materials, can solve the problems of easy damage to the joint structure, lack of analysis methods and methods, and achieve the effect of improving the degree of fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

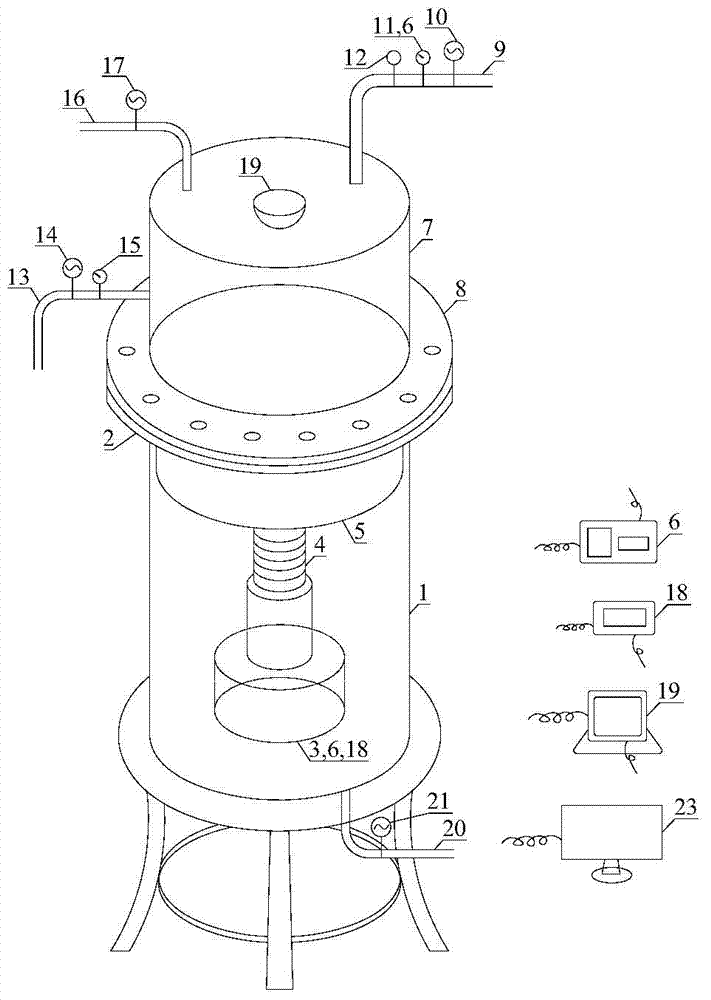

[0025] A mechanical dynamic tester for a joint structure of a flexible anti-seepage body, including pressure chambers 7 and 1, inlet and outlet water / air pipes 9, 13, 16 and 20 valves 10, 14, 17 and 21 systems, mechanical power 3 and a sample installation platform 5 system, displacement 18 and pressure measurement 11 and 15 feedback control system 23 and monitoring system 19, characterized by the above-mentioned pressure chamber 7 and 1 and inlet and outlet water / air pipes 9, 13, 16 and 20 valves 10, 14, 17 and 21 System, mechanical power 3 and sample installation platform 5 system, displacement 18 and pressure measurement 11 and 15 feedback control system 6 and 23 form an overall system of self-control of the test process through sensors, chips and software; pressure chamber 7 and 1 and inlet and outlet water / air pipes 9, 13, 16 and 20 valves 10, 14, 17 and 21 The system consists of upper 7 and lower 1 pressure chambers, inlet and outlet water pipelines 9, 13, 16 and 20 and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com