Method for determining contents of volatile component industrial components of refuse-derived fuel (RDF) and calculating heat value of RDF

A garbage-derived fuel and component content technology, applied in the direction of weighing by removing certain components, can solve problems affecting RDF calorific value, affecting RDF application, RDF composition and content gap, etc., and achieve the effect of simple testing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for determining the industrial component content of volatile components of refuse derived fuel (RDF) and calculating the calorific value, including the following steps:

[0032] (1) Prepare 6 samples of garbage-derived fuel (RDF) in parallel, ground them and air-dry them, and prepare them for the following steps (2)-(7);

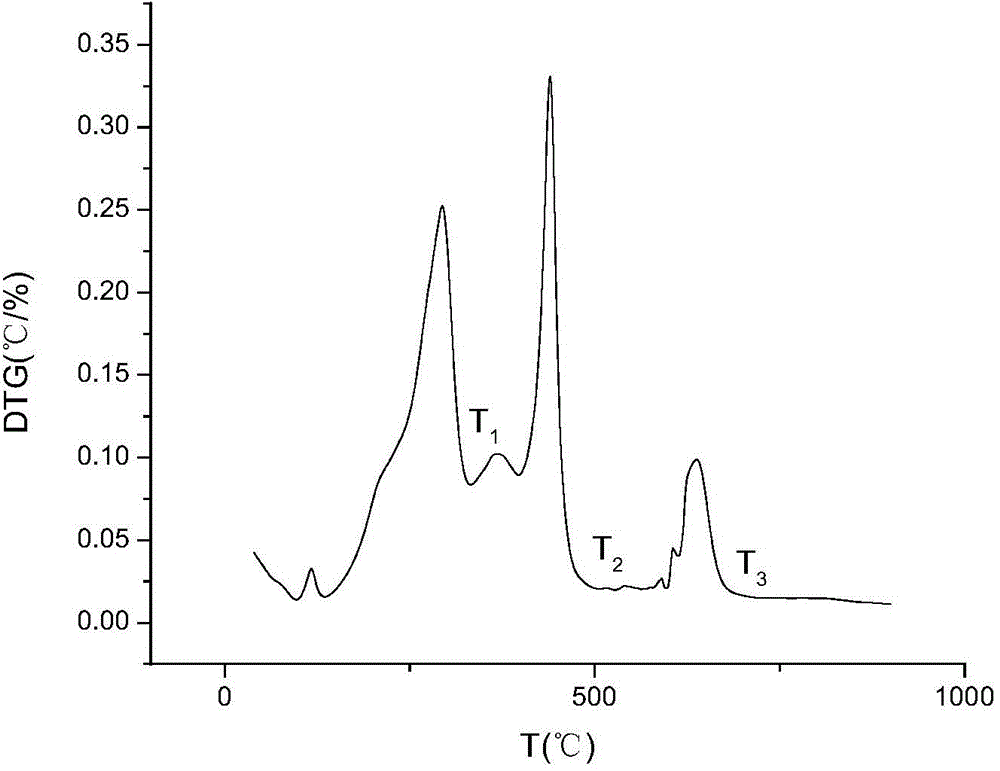

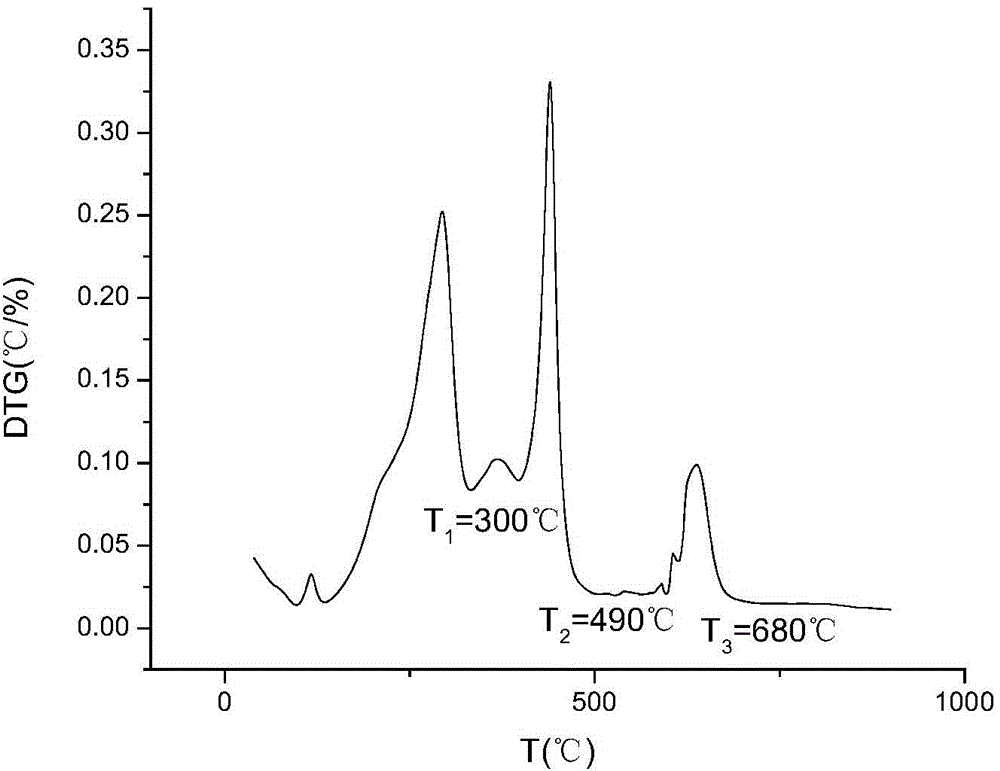

[0033] (2) Take a small amount of RDF samples and put them in a high-resolution thermogravimetric analyzer to obtain a weight loss curve (such as figure 2 Shown) according to figure 2 The characteristic temperature values for the release of volatile matter 1, volatile matter 2 and volatile matter 3 for each characteristic peak are respectively T 1 =300℃、T 2 =490℃ and T 3 =680℃;

[0034] (3) Obtain the moisture content of the RDF sample according to the conventional method: weigh out the empty crucible (with lid) on the analytical balance, then add 2g of the RDF sample (error ±0.001g), open the lid of the crucible, and send the crucible to the tem...

Embodiment 2

[0051] A method for determining the industrial component content of volatile components of refuse derived fuel (RDF) and calculating the calorific value, including the following steps:

[0052] (1) Prepare 6 samples of garbage-derived fuel (RDF) in parallel, ground them and air-dry them, and prepare them for the following steps (2)-(7);

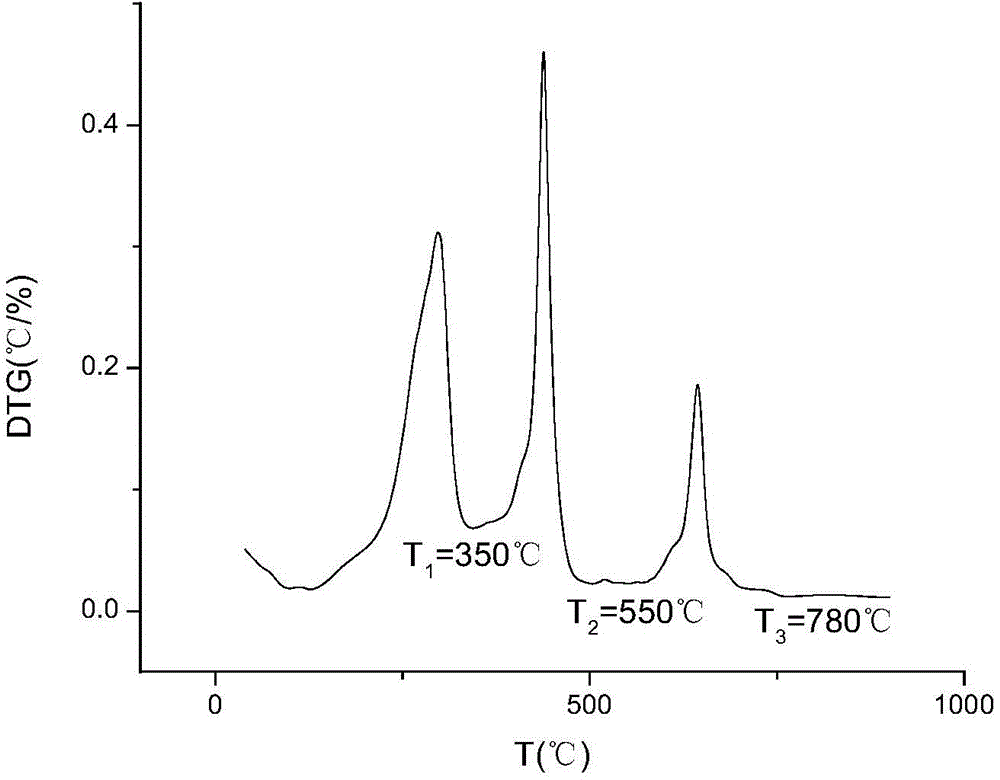

[0053] (2) Take a small amount of RDF samples and put them in a high-resolution thermogravimetric analyzer to obtain a weight loss curve (such as image 3 Shown) according to figure 2 The characteristic temperature values for the release of volatile matter 1, volatile matter 2 and volatile matter 3 for each characteristic peak are respectively T 1 =350℃、T 2 =550℃ and T 3 =780℃;

[0054] (3) Obtain the moisture content of the RDF sample according to the conventional method: weigh out the empty crucible (with lid) on the analytical balance, then add 2g of the RDF sample (error ±0.001g), open the lid of the crucible, and send the crucible to the temp...

Embodiment 3

[0071] A method for determining the industrial component content of volatile components of refuse derived fuel (RDF) and calculating the calorific value, including the following steps:

[0072] (1) Prepare 6 samples of garbage-derived fuel (RDF) in parallel, ground them and air-dry them, and prepare them for the following steps (2)-(7);

[0073] (2) Take a small amount of RDF samples and put them in a high-resolution thermogravimetric analyzer to obtain a weight loss curve (such as image 3 Shown) according to figure 2 The characteristic temperature values for the release of volatile matter 1, volatile matter 2 and volatile matter 3 for each characteristic peak are respectively T 1 =380℃、T 2 =590℃ and T 3 =700℃;

[0074] (3) Obtain the moisture content of the RDF sample according to the conventional method: weigh out the empty crucible (with lid) on the analytical balance, then add 2g of the RDF sample (error ±0.001g), open the lid of the crucible, and send the crucible to the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com