Noise testing method for multi-phase alternating-current permanent magnet motor with even number of units

A permanent magnet motor, noise testing technology, applied in the direction of motor generator testing, etc., can solve problems affecting the accurate testing of motor system noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

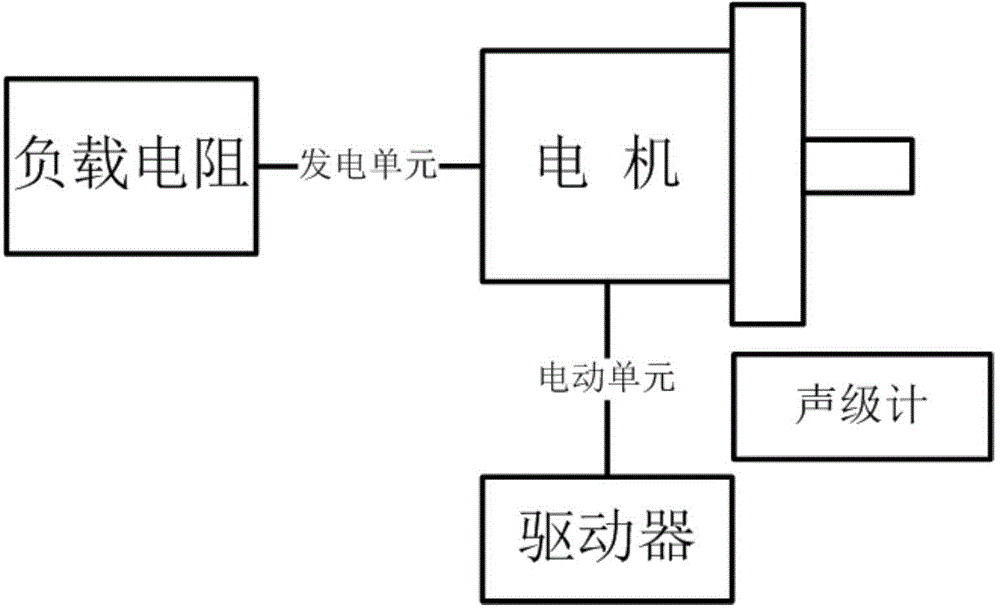

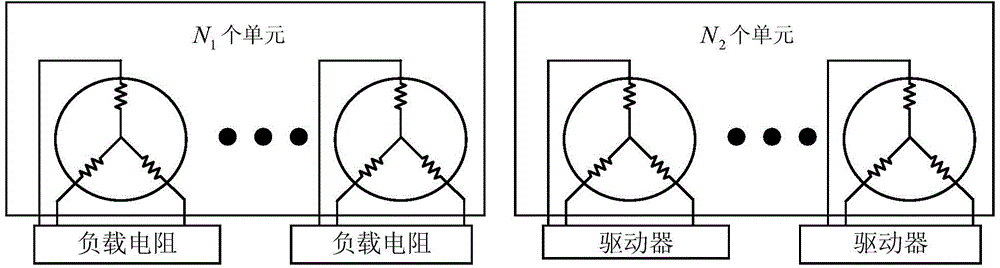

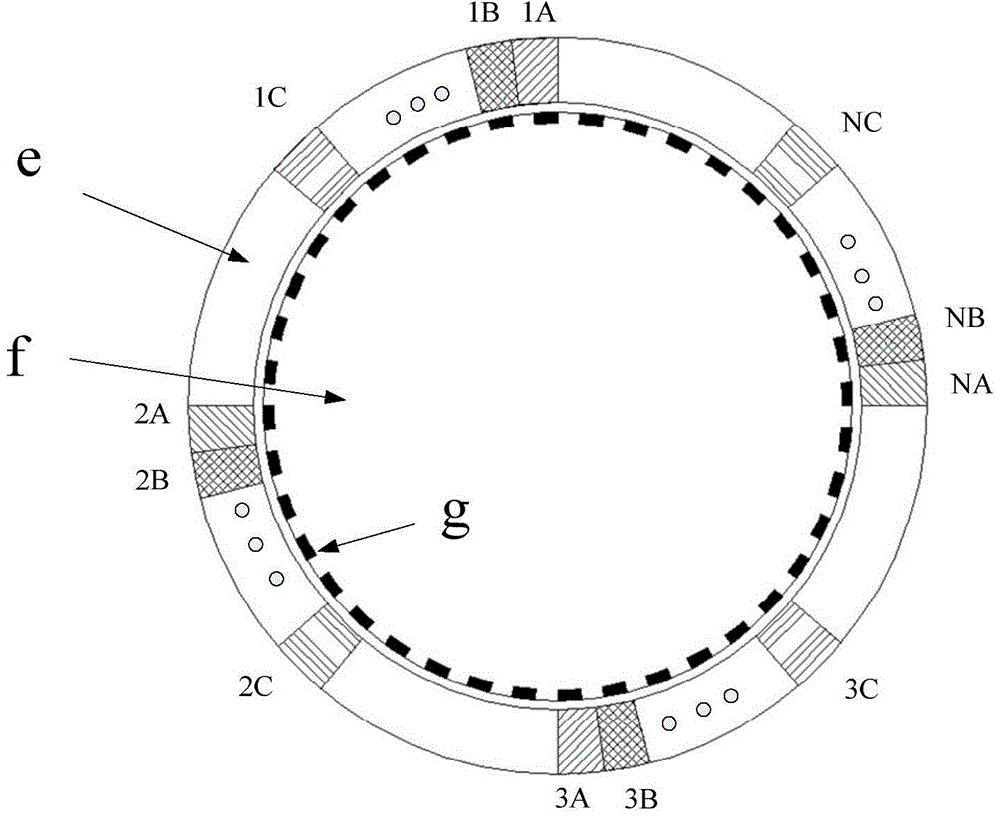

[0032] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, the multi-phase even unit AC permanent magnet motor noise test method described in this embodiment, the stator winding of the motor has N independent operation units, each independent operation unit is a 3-phase symmetrical AC winding, the The number of phases of the motor is 3N, wherein N is an even number greater than 3; the method comprises the following steps:

[0033] Step 1: Measure the curves of the self-inductance and mutual inductance of the stator winding changing with the rotor position within one electrical cycle;

[0034] Step 2: Use the motor to drive the motor to run at a constant speed without load, measure the back EMF of the winding line of the motor at this time, and then calculate the no-load air gap magnetic density through the obtained waveform of the line back EMF;

[0035] Step three:

[0036] Using the three-phase current of the motor, the curve obtained ...

specific Embodiment approach 2

[0044] Specific embodiment 2: This embodiment is a further limitation of the multi-phase even unit AC permanent magnet motor noise test method described in specific embodiment 1. In step 1, the self-inductance and mutual inductance of the stator winding are measured with The method of the curve of rotor position change is:

[0045] Add direct current in an independent operation unit to make the motor be in any position, and add a sinusoidal alternating voltage signal with a direct current bias to both ends of a phase winding of the independent operation unit, and the voltage component of the direct current bias is related to the operating state to be tested The voltage of the lower phase winding is equal;

[0046] Measure the current of the phase winding and the current of other phase windings, so as to obtain the self-inductance of the stator winding and the mutual inductance with other stator windings when the motor is in the position, and change the DC vector in the power s...

specific Embodiment approach 3

[0047] Specific embodiment three: This embodiment is a further limitation of the multi-phase even-number unit AC permanent magnet motor noise test method described in specific embodiment one. In step three, the sound power of the noise generated by the motor under the ideal operating state is the same as that at this time. The specific expression of the equal sound power of the noise generated by the motor in the running state is:

[0048] Σ i = 1 . . . n ( B ′ i ( θ , t ) ) 4 = Σ i ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com