Transformer

A transformer and lamination technology, applied in the field of transformers, can solve problems such as poor contact, power reduction, and reactance reduction, and achieve the effects of avoiding power reduction or coil heating and burning, avoiding varnish damage, and avoiding power reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

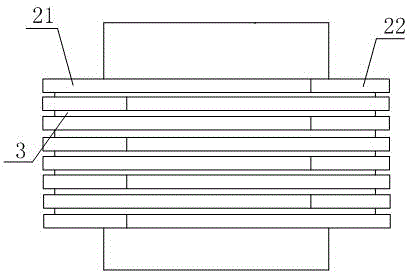

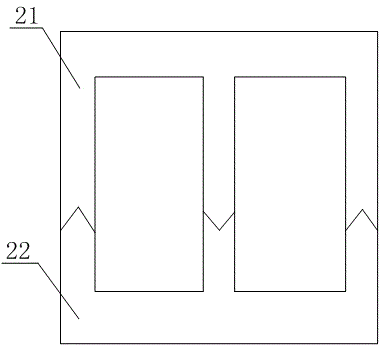

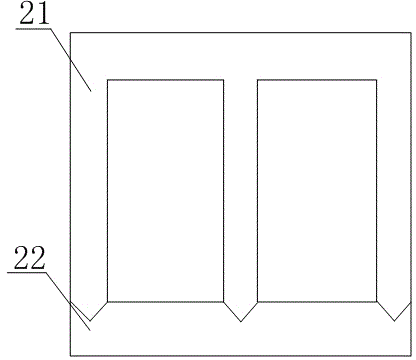

[0020] Such as figure 1 , figure 2 and image 3 The shown transformer includes a core element, and the core element includes a plurality of flat laminations stacked adjacent to each other so as to be in parallel, and the laminations include E laminations 21 and E laminations 21 constitutes the second laminated sheet 22 in the shape of a "day", the contact part of the E laminated sheet 21 and the second laminated sheet 22 is provided with teeth that engage with each other, and an anti-slip layer 3 is provided between the laminated sheets. The antiskid layer 3 is provided with holes. The stitching method between the E lamination and the second lamination is the same as that of the prior art, and has the same thickness. The center arm of the E-stack is located in the center of the spool 1.

Embodiment 2

[0022] Such as figure 1 and figure 2 In the shown transformer, this embodiment is based on the above-mentioned embodiment, and an implementation mode is preferred for the second lamination, that is, the cross-section of the second lamination 22 is "E"-shaped. The section of the second lamination 22 is "E" shape, which increases the contact area of the second lamination 22 with the anti-skid layer, so that the second lamination 22 is not easy to be pulled off, which is a preferred embodiment.

Embodiment 3

[0024] Such as figure 1 and image 3 In the shown transformer, this embodiment is based on the above-mentioned embodiment, and an implementation mode is preferred for the second lamination, and the cross-section of the second lamination 22 is "I" shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com