Aloft containing and taking device and method for aloft test wires of power system

A power system and test line technology, applied in the direction of electrical connection socket, clip connection conductor connection, etc., can solve problems such as low efficiency, safe burial of field workers, hidden dangers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

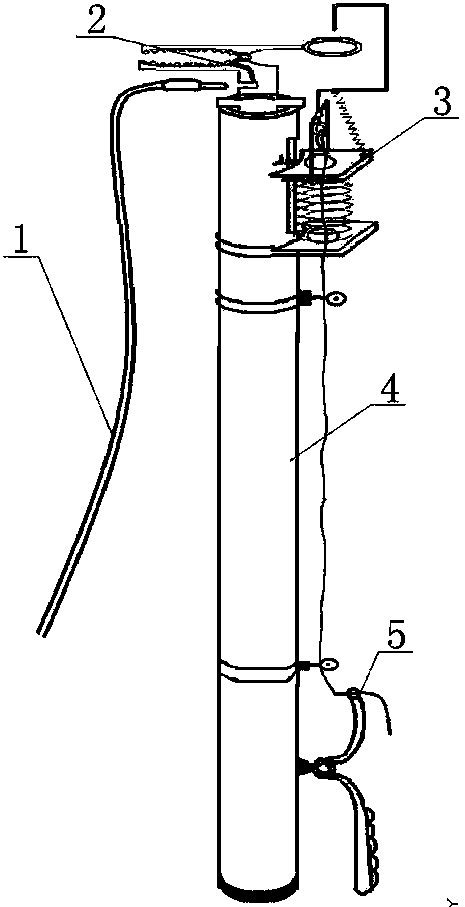

[0037] Embodiment 1: as Figure 1-9 As shown, a high-altitude loading and unloading device for power system high-altitude test lines includes an insulating rod 4, a clamping mechanism 2 located at one end of the insulating rod 4, and a self-releasing mechanism 3 arranged at one end of the insulating rod for controlling the opening of the clamping mechanism. .

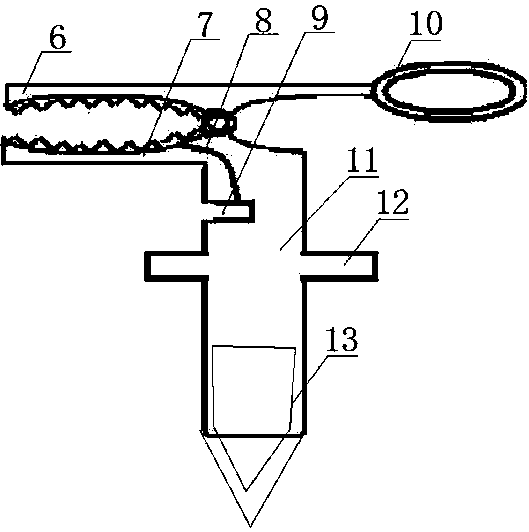

[0038] The clamping mechanism includes an elastic wire clamp 6, an insulating cylinder 11 vertically connected to it is arranged on one clamp arm of the elastic wire clamp 6, and a snap ring 10 is horizontally arranged on the other clamp arm of the elastic wire clamp 6 , the insulating cylinder 11 is provided with a test line socket 9 connected to the elastic clamp 6 through a wire 8 .

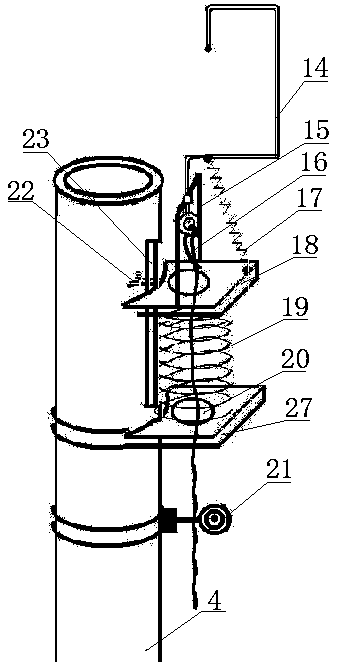

[0039] The self-releasing mechanism includes a lower insulating plate 27 fixedly arranged at one end of the insulating rod 4, an upper insulating plate 18 which is arranged on the upper part of the lower insulating plate 27 and is slid...

Embodiment 2

[0059] Embodiment 2: as Figure 1-9 As shown, a high-altitude loading and unloading device for power system high-altitude test lines includes an insulating rod 4, a clamping mechanism 2 located at one end of the insulating rod 4, and a self-releasing mechanism 3 arranged at one end of the insulating rod for controlling the opening of the clamping mechanism. .

[0060] The clamping mechanism includes an elastic wire clamp 6, an insulating cylinder 11 vertically connected to it is arranged on one clamp arm of the elastic wire clamp 6, and a snap ring 10 is horizontally arranged on the other clamp arm of the elastic wire clamp 6 , the insulating cylinder 11 is provided with a test line socket 9 connected to the elastic clamp 6 through a wire 8 .

[0061] The self-releasing mechanism includes a lower insulating plate 27 fixedly arranged at one end of the insulating rod 4, an upper insulating plate 18 which is arranged on the upper part of the lower insulating plate 27 and is slid...

Embodiment 3

[0081] Embodiment 3: as Figure 1-9 As shown, a high-altitude loading and unloading device for power system high-altitude test lines includes an insulating rod 4, a clamping mechanism 2 located at one end of the insulating rod 4, and a self-releasing mechanism 3 arranged at one end of the insulating rod for controlling the opening of the clamping mechanism. .

[0082] The clamping mechanism includes an elastic wire clamp 6, an insulating cylinder 11 vertically connected to it is arranged on one clamp arm of the elastic wire clamp 6, and a snap ring 10 is horizontally arranged on the other clamp arm of the elastic wire clamp 6 , the insulating cylinder 11 is provided with a test line socket 9 connected to the elastic clamp 6 through a wire 8 .

[0083] The self-releasing mechanism includes a lower insulating plate 27 fixedly arranged at one end of the insulating rod 4, an upper insulating plate 18 which is arranged on the upper part of the lower insulating plate 27 and is slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com