heat-curing reactive systems

A technology of thermal curing and vulcanizing agent, used in the field of sound damping adhesives, sealants or coating compositions, it can solve the problems of only using materials, cannot be removed, large coating thickness, etc., and achieve excellent mechanical properties, wide spraying fan shape , the effect of good ease of application

Active Publication Date: 2017-02-22

HENKEL KGAA

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, these systems have disadvantages, especially for industrial applications with high production volumes; because water cannot be removed from the sprayed coating quickly enough due to the large coating thickness

Another disadvantage of these conventional methods of sound attenuation is that these materials are used for the single purpose of sound attenuation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

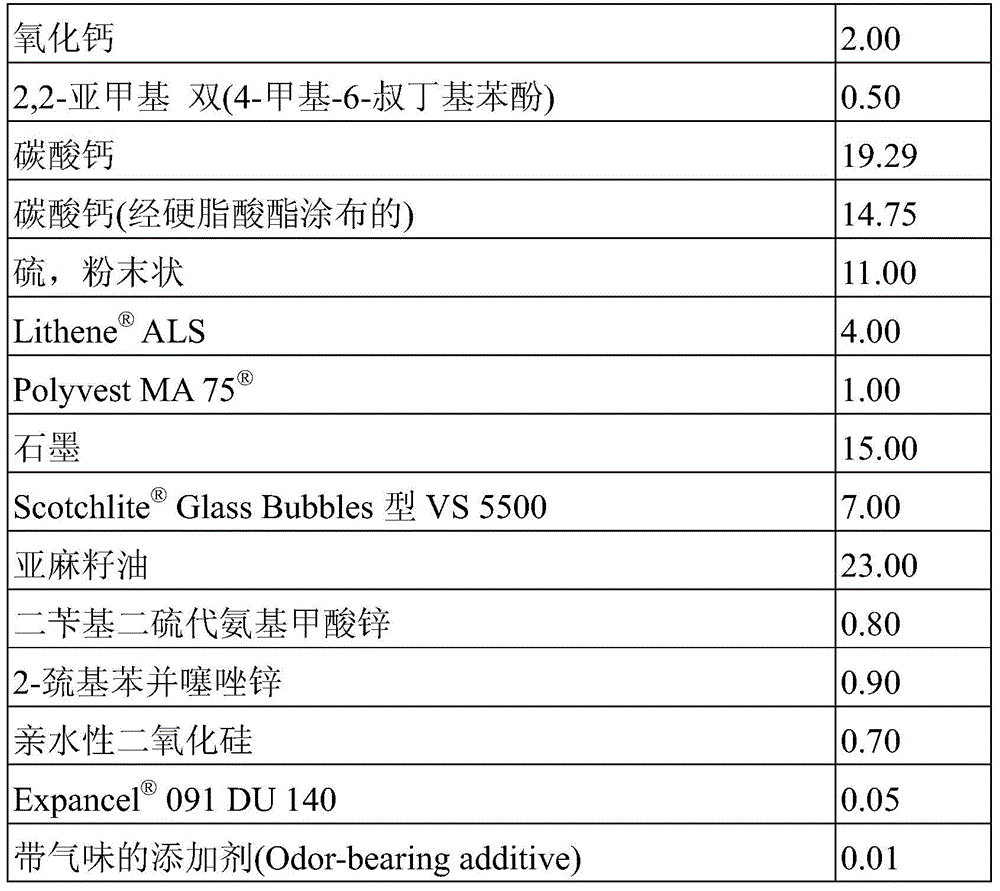

Embodiment 1

[0185]

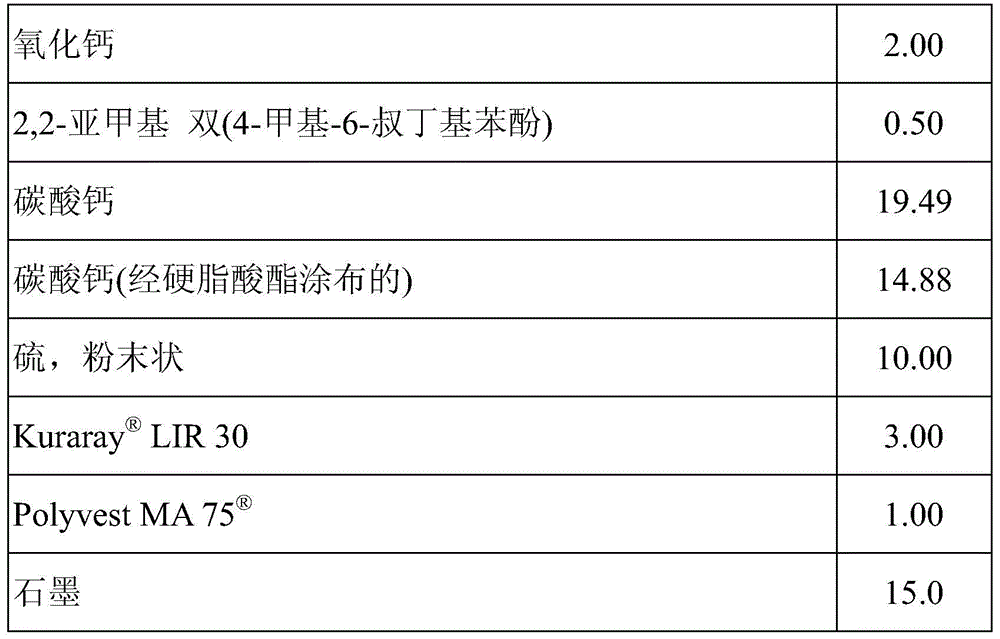

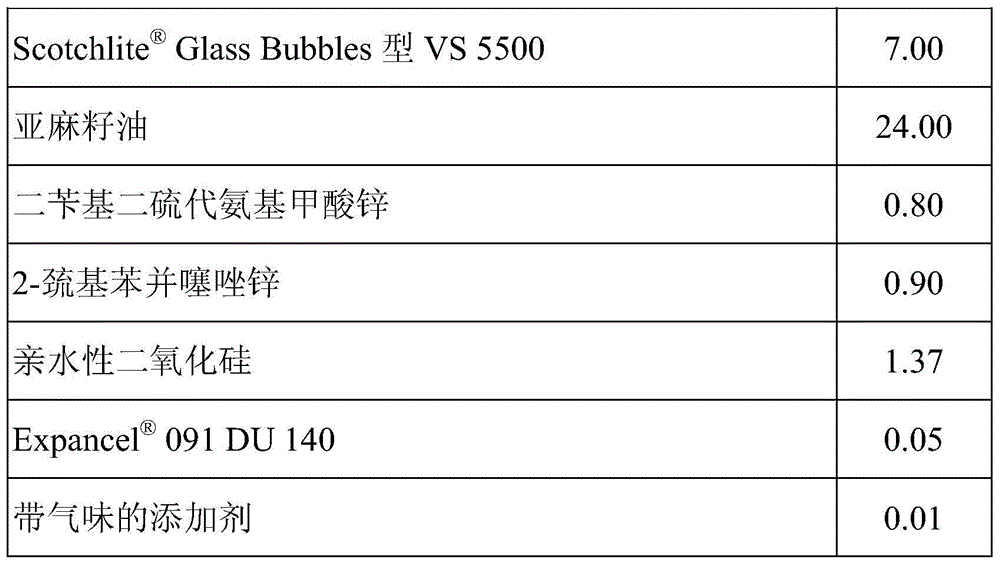

Embodiment 2

[0187]

[0188]

Embodiment 3

[0190]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to thermosetting formulations comprising (a) a triglyceride fraction whose fatty acid distribution contains at least 5% by weight, especially at least 60% by weight, of one or more omega-3 fatty acids and / or one or more omega-6 fatty acids; (b) at least one vulcanizing agent selected from the group consisting of (b1) sulfur, (b2) peroxide vulcanizing agents, (b3) quinones and / or quinonedioximes, and / or (b4) disulfides nitrobenzene; and (c) at least one inorganic filler.

Description

technical field [0001] The present application relates to thermosetting formulations based on triglyceride moieties containing omega-3 fatty acids and / or omega-3 fatty acids, to a process for preparing said formulations, and also to said formulations as acoustic damping adhesives, sealants or Use of coating compositions. Background technique [0002] Metal sheets with very thin walls are commonly used in the production of automobiles, machines and devices to reduce their weight. Mechanically moving parts or running motors inevitably cause these thin-walled metal plates to vibrate at frequencies usually within the audible range of the human ear. These vibrations are propagated through the entire vehicle, machine or installation in the form of solid-borne sound, which can be released into the air at a distance as disturbing noise. Therefore, in order to reduce the sound emission and eliminate the structure-borne sound, the thin-walled metal sheets used, especially in the man...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09J123/22C09J109/00C08K5/09C08L21/00C08K3/00C08K5/00C08K5/103C08L9/00C08L9/06C08L13/00

CPCC08K5/0025C08K5/103C09J109/00C08L9/00C08L9/06C08L13/00C08L21/00C08K3/013B05D1/02B05D3/0254C09D5/00C09D147/00C09J5/00C09J9/00C09J147/00

Inventor R·绍尔P·博恩M·米勒

Owner HENKEL KGAA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com