Tea leaf carding machine

The technology of a tea strip machine and a box body is applied in the field of tea machinery, which can solve the problems of inconvenient operation, single shape of tea leaves, scalding of the operator's hand, etc., and achieve the effect of convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below with reference to the embodiments of the drawings:

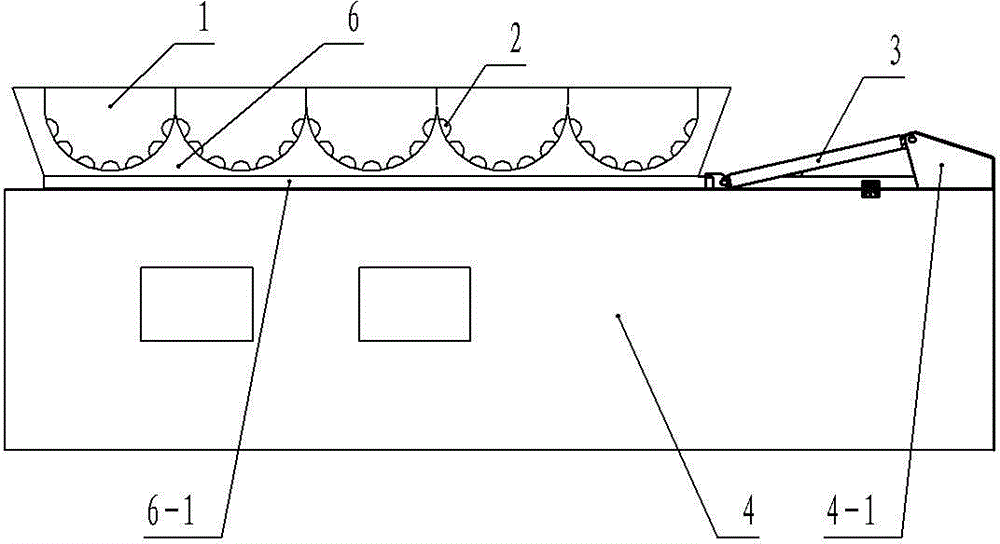

[0011] figure 1 The tea leaf sorting machine shown includes a box body 4 and a trough pot seat 6 arranged on the box body 4. A trough pot 1 is provided in the trough pot seat 6 and a plurality of circular protrusions are provided on the inner wall of the trough pot 1 2. The trough pot holder 6 has a bottom plate 6-1, and the end of the bottom plate close to the oil cylinder 3 extends outwards and is connected with the oil cylinder 3; the upper part of the box body 4 is fixedly connected with an upwardly extending mounting plate 4-1, the oil cylinder 3 The other end is connected to the mounting plate 4-1.

[0012] When working, the tea leaves are thrown, smashed, and rolled in the trough pot. Because the inner wall of the trough pot is provided with a number of circular protrusions, the tea leaves that are arranged have a curved shape, beautiful and unique; A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com