Method and apparatus for filtering liquid bubbles

A technology of liquid bubbles and equipment, applied in the directions of liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of finished product quality, easy access to finished products, etc., to improve the yield of finished products, solve defective products, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

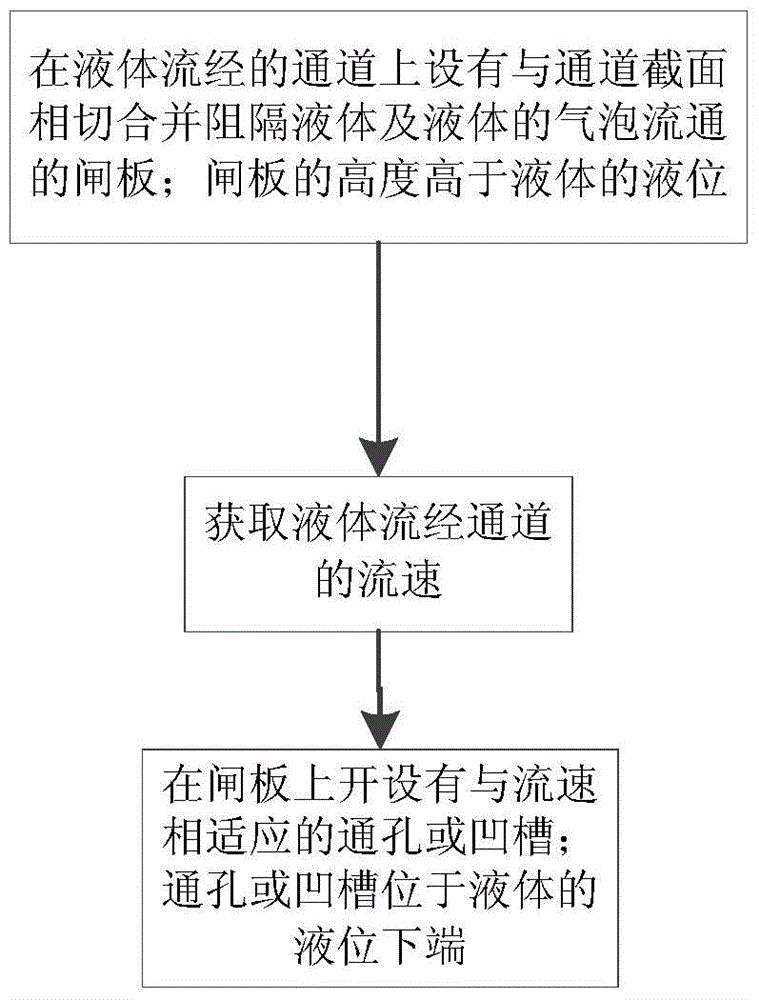

[0023] Such as figure 1 Shown is a method for filtering liquid bubbles, comprising the steps of:

[0024] S1, the channel through which the liquid flows is provided with a gate 3 that is tangent to the cross section of the channel and blocks the flow of liquid and liquid bubbles; the height of the gate 3 is higher than the liquid level of the liquid;

[0025] S2, obtaining the flow velocity of the liquid flowing through the channel, and the bubbles of the liquid float above the liquid surface;

[0026] S3, there are through holes or grooves adapted to the flow velocity on the gate plate; the through holes or grooves are located at the lower end of the liquid level, and the gate plate blocks the flow of air bubbles in the liquid.

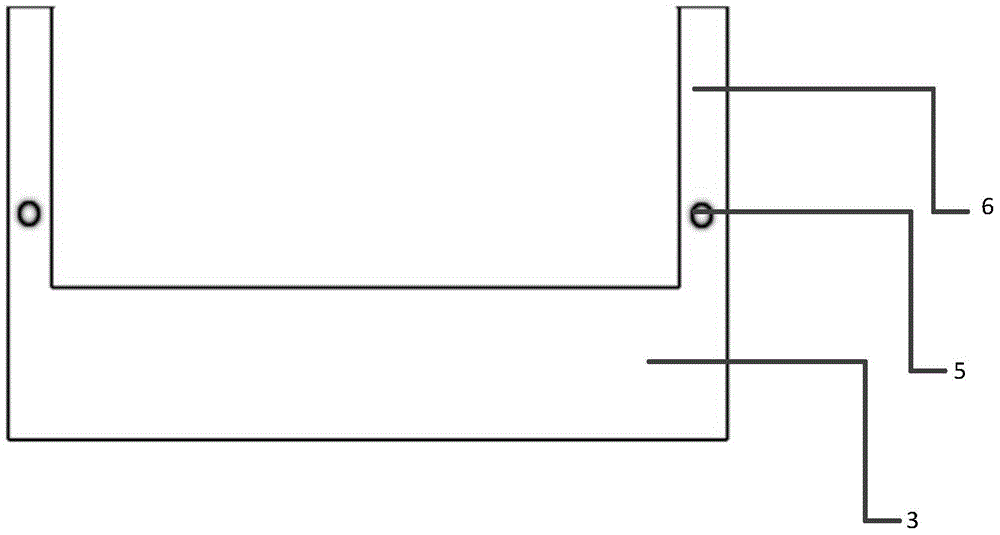

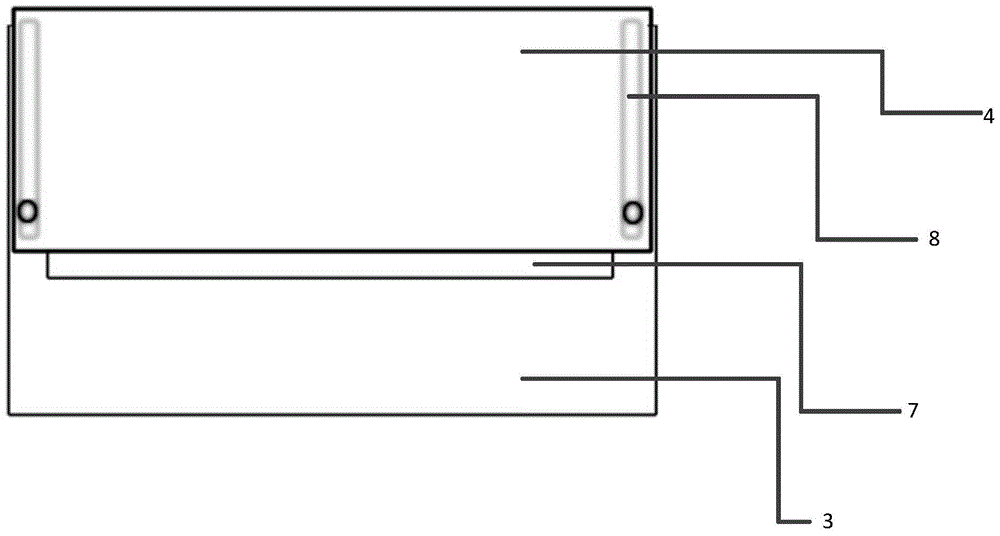

[0027] Such as Figure 2-3 The device for filtering liquid bubbles shown includes a gate 3; the gate 3 is closely attached to the bottom edge and the surrounding of the liquid circulation vessel; the middle position of the gate 3 has a liquid flowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com