Stereoscopic rapid heating device and heating method of hot stamping blank

A hot stamping forming and rapid heating technology is applied in the field of three-dimensional rapid heating devices for hot stamping forming blanks, which can solve the problems of decreased heating efficiency, poor equipment flexibility, poor temperature uniformity of sheet materials, etc., to improve uniformity and save energy. , The effect of good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

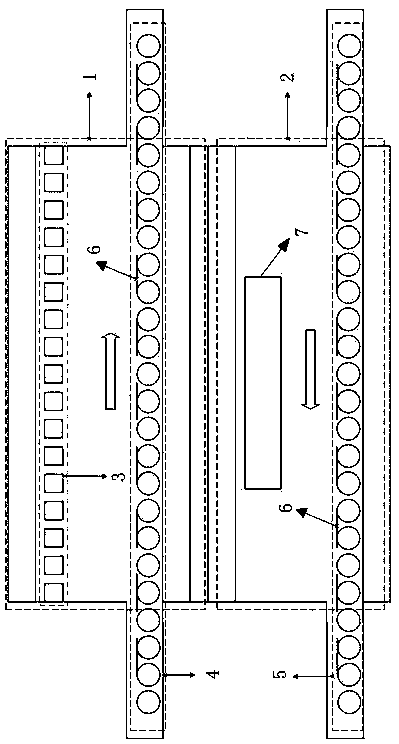

[0019] Such as figure 1 As shown, a three-dimensional rapid heating device for hot stamping blanks includes a first heating chamber 1 and a second heating chamber 2, and the first heating chamber 1 and the second heating chamber 2 are respectively equipped with a first temperature-resistant conveying mechanism 4 and the second temperature-resistant conveying mechanism 5, the first heating chamber 1 is provided with a plurality of infrared heating lamp tubes 3 for heating the blank 6 along the first temperature-resistant conveying mechanism 4, and the second heating chamber 2 is provided There is an electric furnace 7 for heating the billet 6 .

[0020] The heating device of the present inve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com