Sand mold structure of oil pan casting

A technology for sand molds and castings, applied in the field of sand mold structures, can solve the problems of large heat loss, sand inclusion defects, and pore sand inclusion defects in molten iron, and achieve the effects of improving quality and dimensional accuracy, reducing sand inclusion in molten iron, and improving the quality of molten iron.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

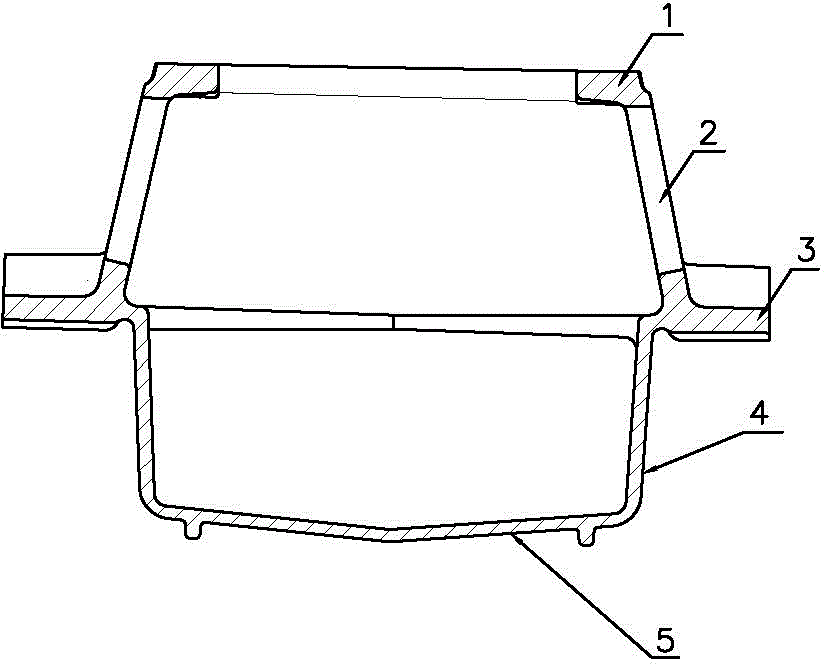

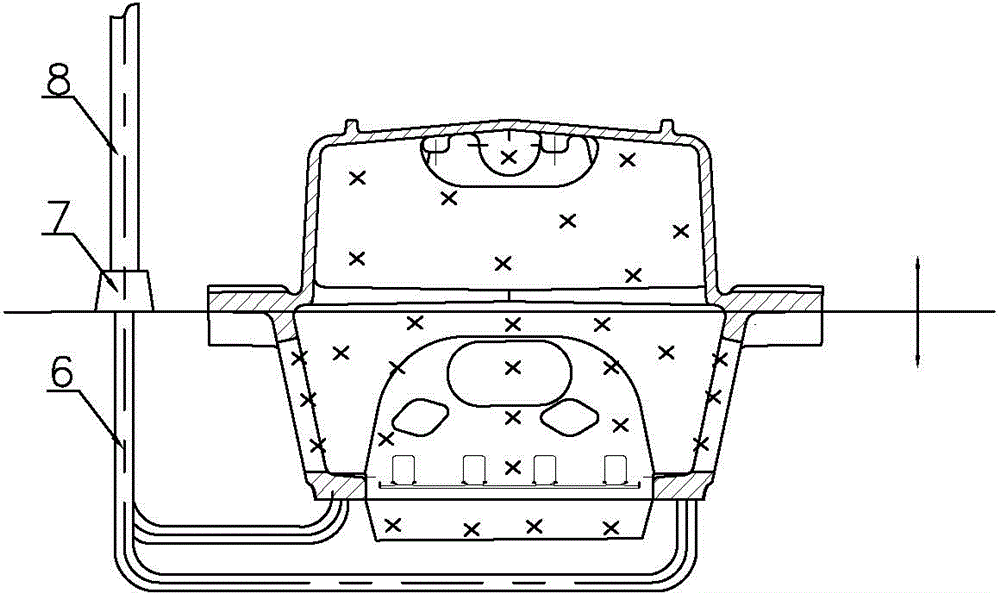

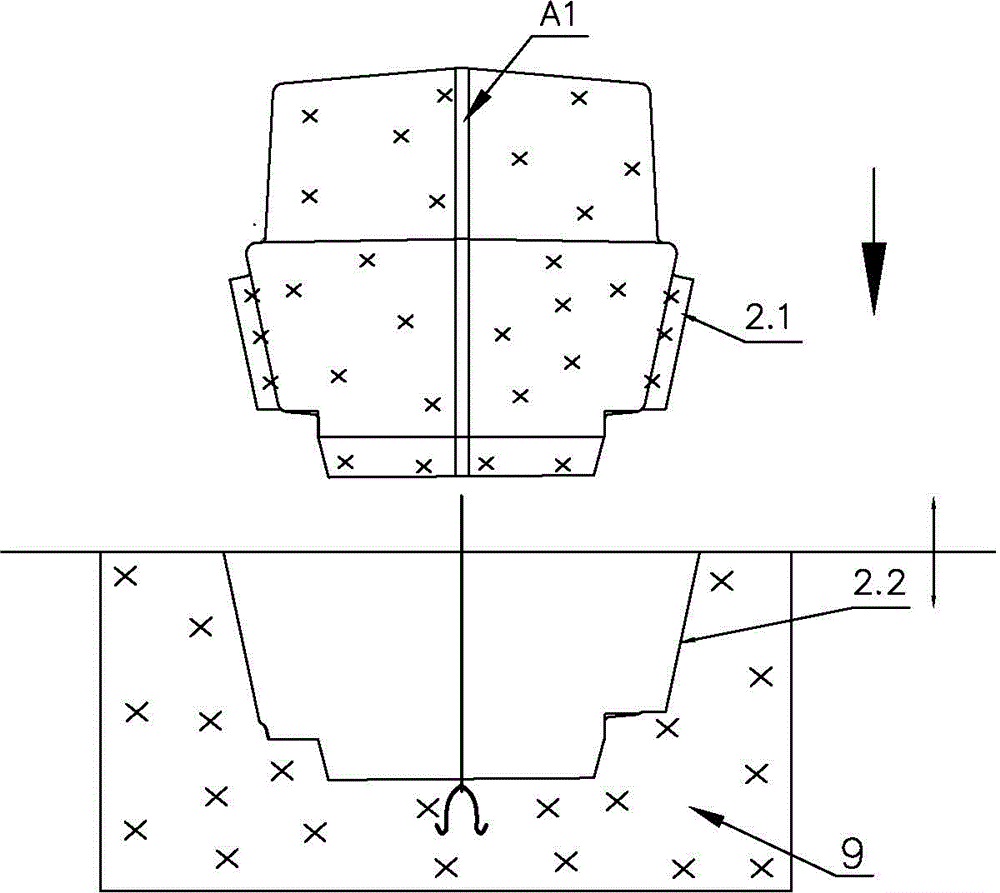

[0020] like Image 6 and Figure 7 Shown is the sand mold structure of the oil pan casting of the present invention, the sand mold of the oil pan casting includes an upper sand mold 10, a lower sand mold 9 and a core 11, and the corresponding mold cavities of the flange 3 of the oil pan casting are vertically arranged on the upper In the sand mold 10 and the lower sand mold 9, it is equivalent to rotating the mold cavity by 90° relative to the sand mold structure in the prior art. The parting surface 12 of the upper sand mold 10 and the lower sand mold 9 is perpendicular to the molding surface corresponding to the top plane and the bottom surface of the casting. The forming structures corresponding to the square doors 2 on the two side walls of the pan casting are respectively arranged on the upper side of the upper sand mold 10 and the lower side of the lower sand mold 9. The mold gating system of the oil pan casting adopts the bottom gating system, including sprue 8, horizon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com