Sorting and assembling equipment for valve lock clamp components

A technology for assembling equipment and valve lock clips, which is used in sorting, assembling machines, metal processing equipment, etc., and can solve problems such as affecting assembly work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

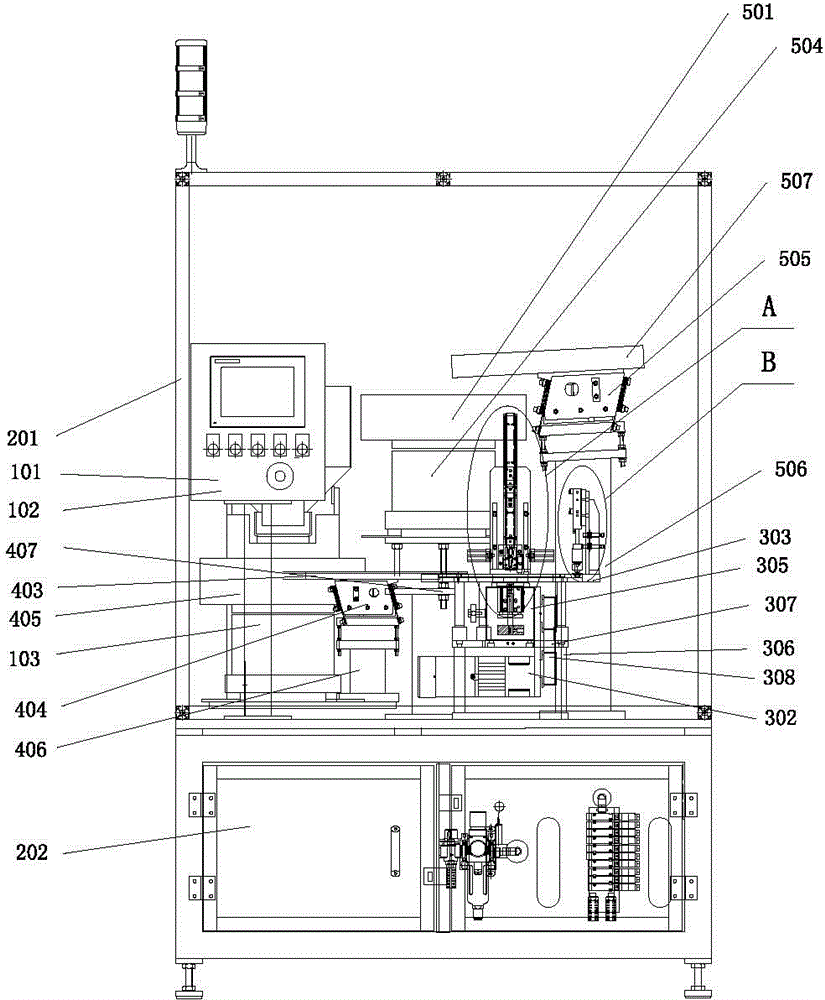

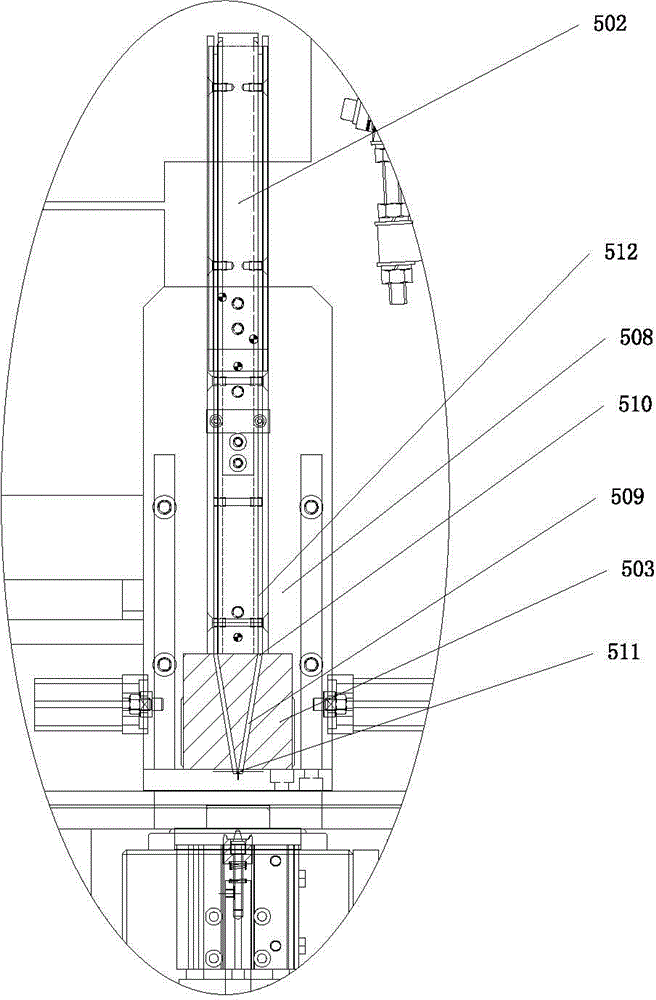

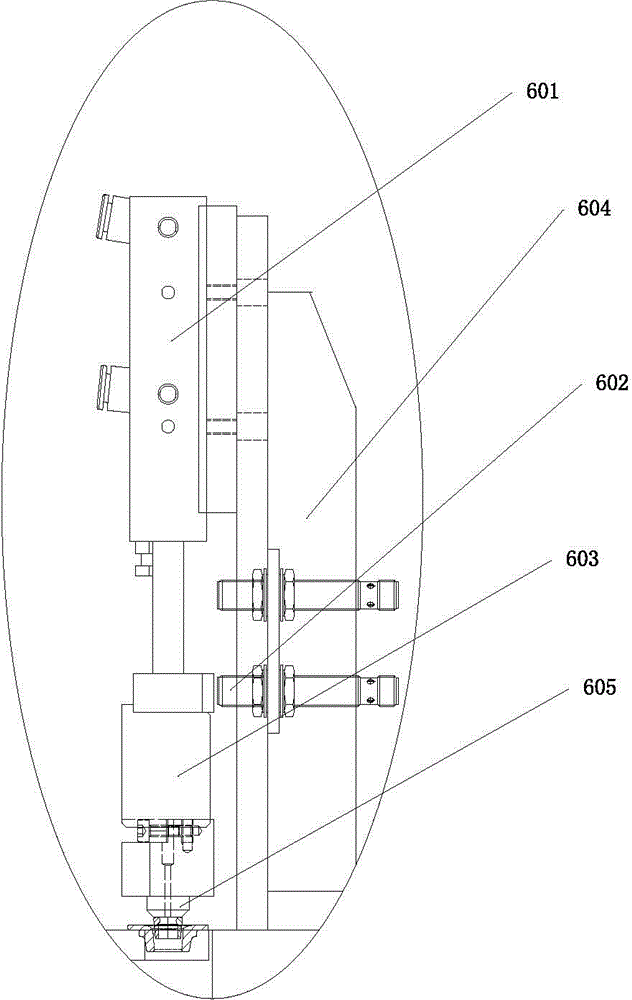

[0026] Depend on Figure 1 to Figure 6 As shown, the present invention includes a protection assembly, a turntable mechanism, a spring seat feeding mechanism, a lock clip fitting mechanism, a fitting detection mechanism, an automatic discharging mechanism, a material picking mechanism and an operation box assembly 101 .

[0027] Depend on figure 1As shown, the protective assembly includes a rectangular frame body 201 and a cabinet body 202, the frame body 201 is arranged on the upper end of the cabinet body 202, the operation box assembly 101 includes an operation box 102 and an operation box bracket 103, and the lower end of the operation box bracket 103 is connected to the The cabinet body 202 is connected, and the lower end of the operation box bracket 103 is connected with the operation box 102 .

[0028] Depend on figure 1 and Figure 4 As shown, the turntable mechanism includes an indexing turntable 301, a motor 302, a speed reducer 305 and an indexing platform 303, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com