Automatic control processing system for bottom surface of crystallizing tank

A processing system and crystallization tank technology, applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece support, etc., can solve the problems of low production efficiency, easy to break, complex equipment, etc., and achieve simple structure, low cost, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

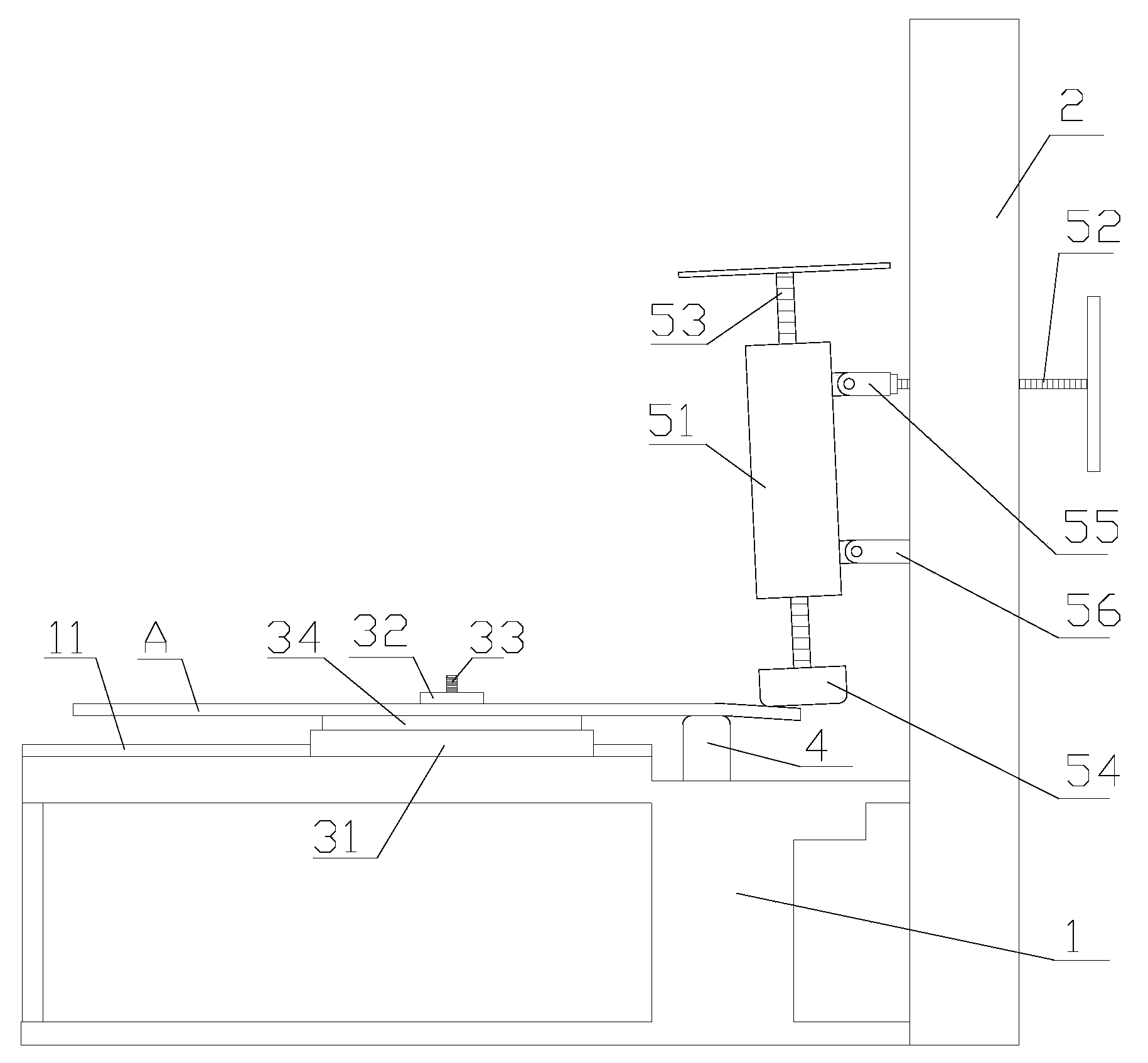

[0031] refer to figure 2 , a crystallization tank bottom surface automatic control processing system proposed by the present invention, comprising: a base 1, a support frame 2, a workpiece support mechanism, a turntable 4, an extrusion mechanism, a control module, a first motor, a second motor, and a third motor and fourth motor.

[0032] The base 1 is provided with a linear track 11 , and the support frame 2 is installed vertically and connected with the base 1 .

[0033] The workpiece supporting mechanism includes a moving table 31 , a backing plate 34 and a pressure plate 32 . The mobile platform 31 is movably installed on the track 11 , and the first motor is used to drive the mobile platform 31 to move. The center position of the upper surface of the mobile platform 31 is provided with a positioning column 33, and the backing plate 34 is provided with a central hole and can be rotatably installed on the mobile platform 31 through a clearance fit with the positioning co...

Embodiment 2

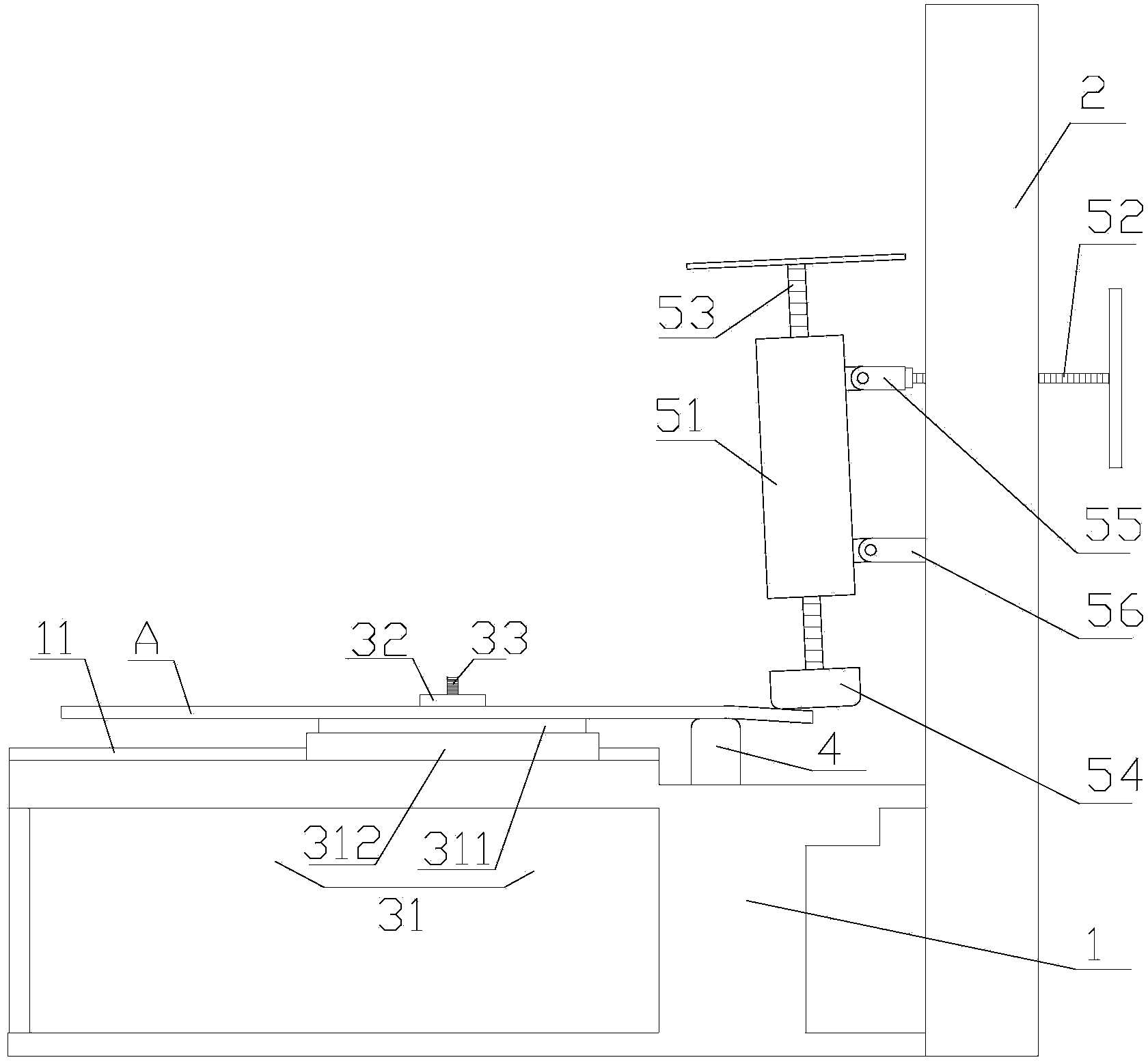

[0050] refer to image 3 , a crystallization tank bottom surface automatic control processing system proposed by the present invention, comprising: a base 1, a support frame 2, a workpiece support mechanism, a turntable 4, an extrusion mechanism, a control module, a first motor, a second motor, and a third motor and fourth motor.

[0051] The base 1 is provided with a linear track 11 , and the support frame 2 is installed vertically and connected with the base 1 .

[0052] The workpiece supporting mechanism includes a moving table 31 and a pressure plate 32 . The mobile station 31 is composed of an upper platform 311 and a lower platform 312 . The lower platform 312 is movably installed on the track 11, and the first motor is used to drive the lower platform 312 to move. The upper platform 311 is rotatably mounted on the lower platform 312 . The center position of the upper surface of the upper platform 311 is provided with a positioning column 33, and the plate-shaped wor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com