Adsorber

A technology of adsorber and body, which is applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of destroying fluid flow state, unstable suction force, providing friction force, etc., and achieve the effect of avoiding flow disorder and benefiting suction force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

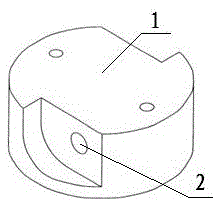

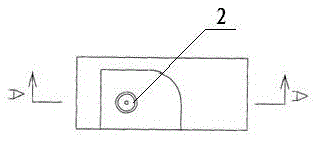

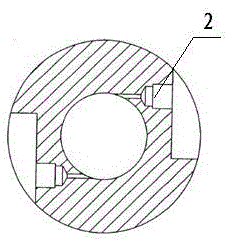

[0031] Such as Figure 8 with Figure 9 The illustrated embodiment includes a body 11, which has a circular cavity 11-1 with a circular cross section. The cavity 11-1 has a closed end face and an open end face, and the open end face forms an end face for absorbing objects. On the inner wall of 11, there is a tangentially arranged nozzle 12 that communicates with the fluid supply source inside and outside the cavity 11-1. The fluid ejected from the nozzle generates a swirling flow inside the cavity 11-1. There can be one or more nozzles One, distributed equidistantly along the circumferential direction of the cylindrical cavity, the body 11 is provided with an annular bottom plate 13 below it, and a top plate 14 is arranged above it, and the annular bottom plate 13 and the top plate 14 are arranged on the two side walls of the body 11 The two connecting rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com