a printing machine

A printing machine and printing arm technology, which is applied to printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of elastic platen breakage, affecting the positioning accuracy, and aggravating the vibration of the elastic platen, so as to prevent dust from entering , to avoid the accuracy of positioning, to avoid the effect of head-to-head

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

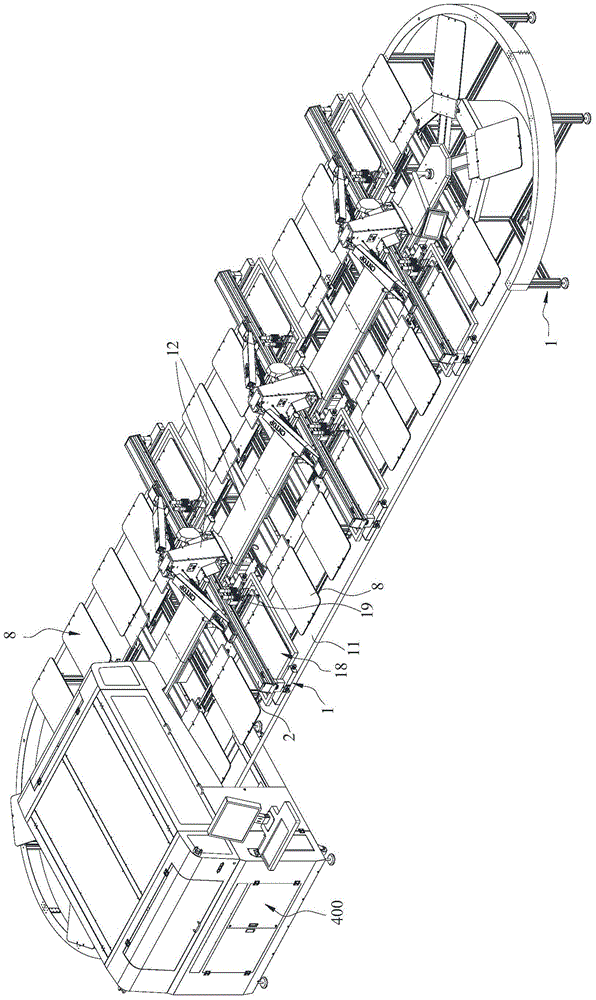

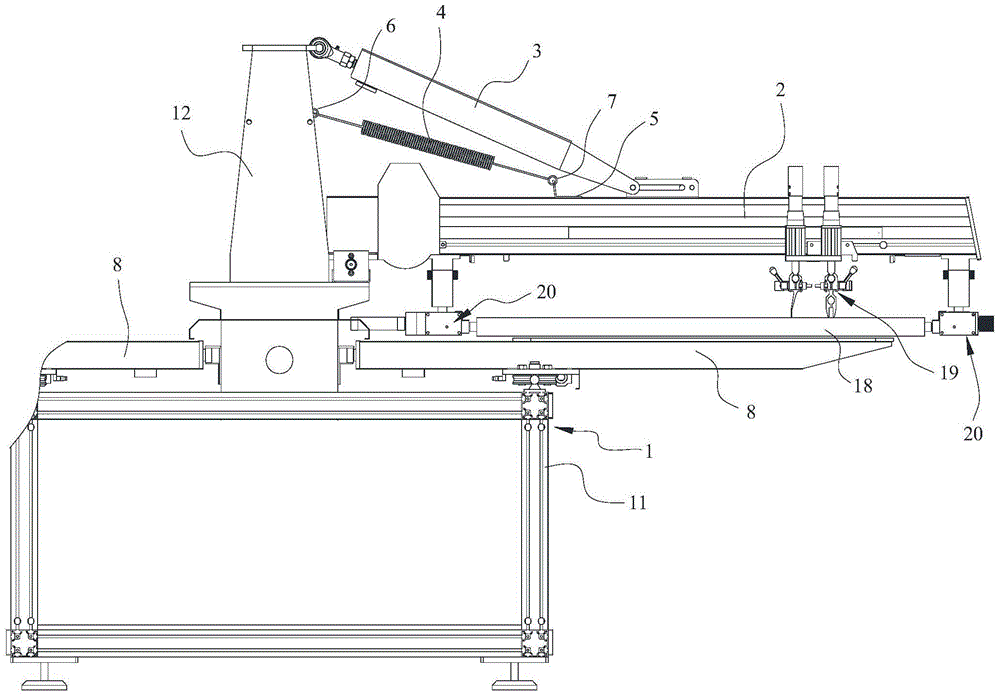

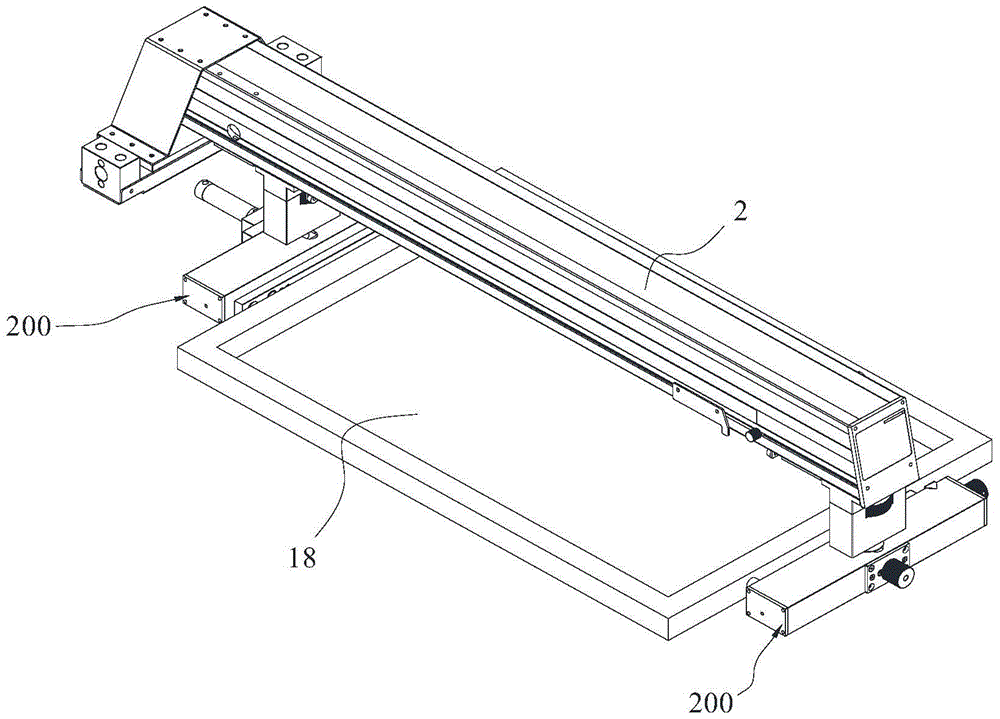

[0034] Such as Figure 1~3A kind of printing machine shown, comprises stand 1, printing arm 2, air cylinder 3, tension spring 4, elastic platen 8, screen frame 18, the scraper 19 that slides fits in printing arm 2 and is fixed on printing arm 2 Screen frame fixing device 20, platform 1 comprises frame foot 11 and the fixed arm 12 that is fixed on this frame foot 11, and fixed arm 12 is straight line, and frame foot 11 is arranged around the periphery of fixed arm 12, and specifically can be wound into ellipse One end of the printing arm 2 is hinged with the lower part of the fixed arm 12, the piston rod of the cylinder 3 is stretched out from one end of the cylinder body of the cylinder 3 and is hinged with the upper end of the fixed arm 12, the other end of the cylinder body of the cylinder 3 is connected with the printing arm 2 The middle part is hinged and slidably matched with the printing arm 2 along the length direction of the printing arm 2; one end of the tension sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com