Elevating device for changing material position

A lifting device, a lifting device technology, applied in the conveyor control device, conveyor objects, transportation and packaging, etc., can solve the problems of easy falling, falling into the ground, unstable center of gravity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

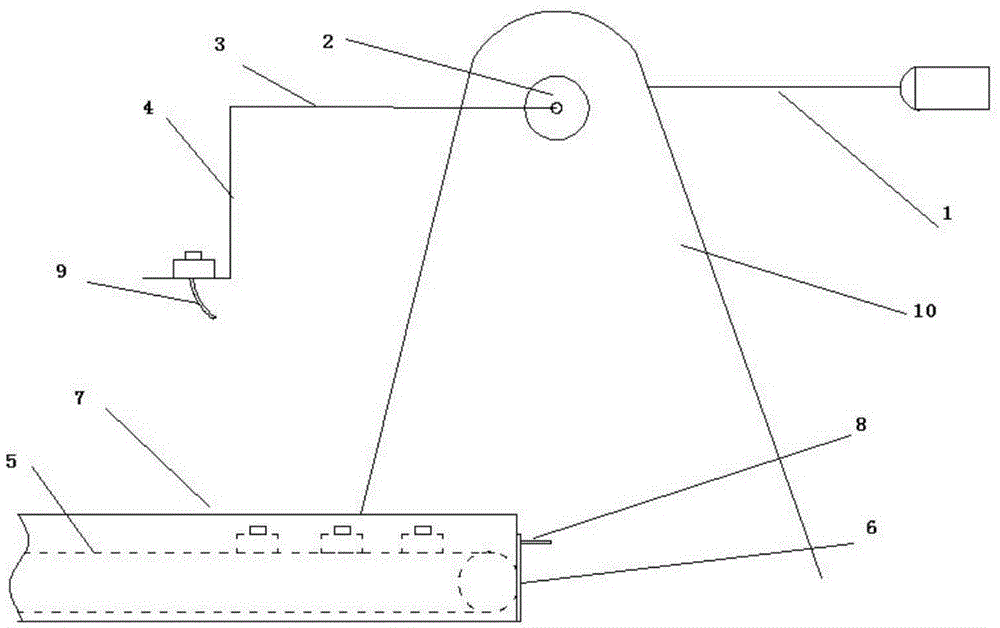

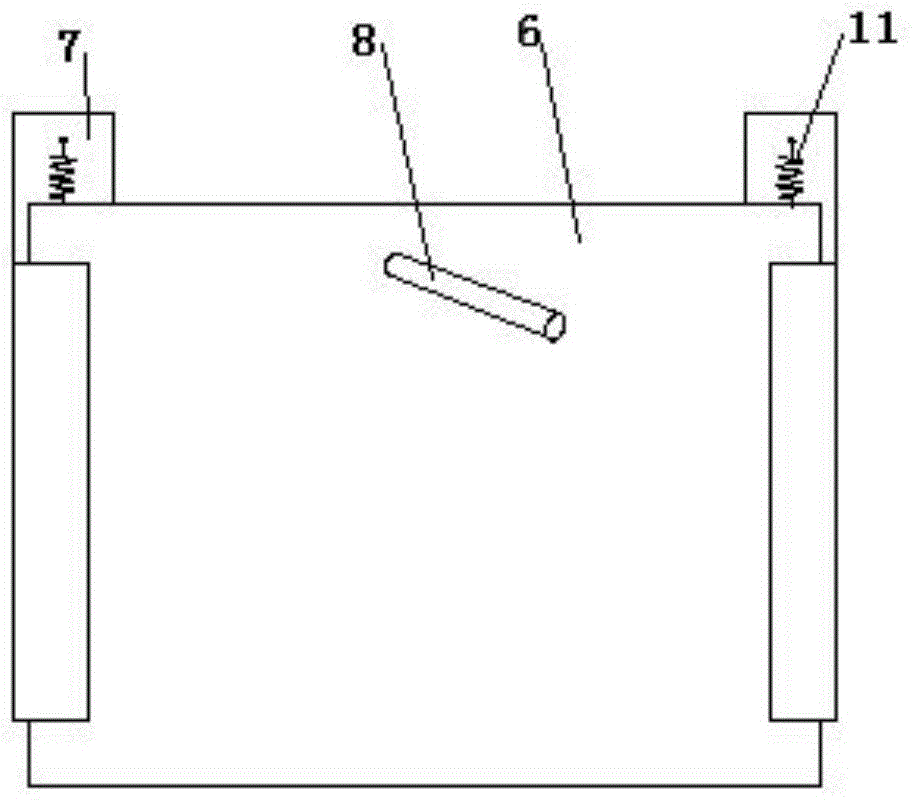

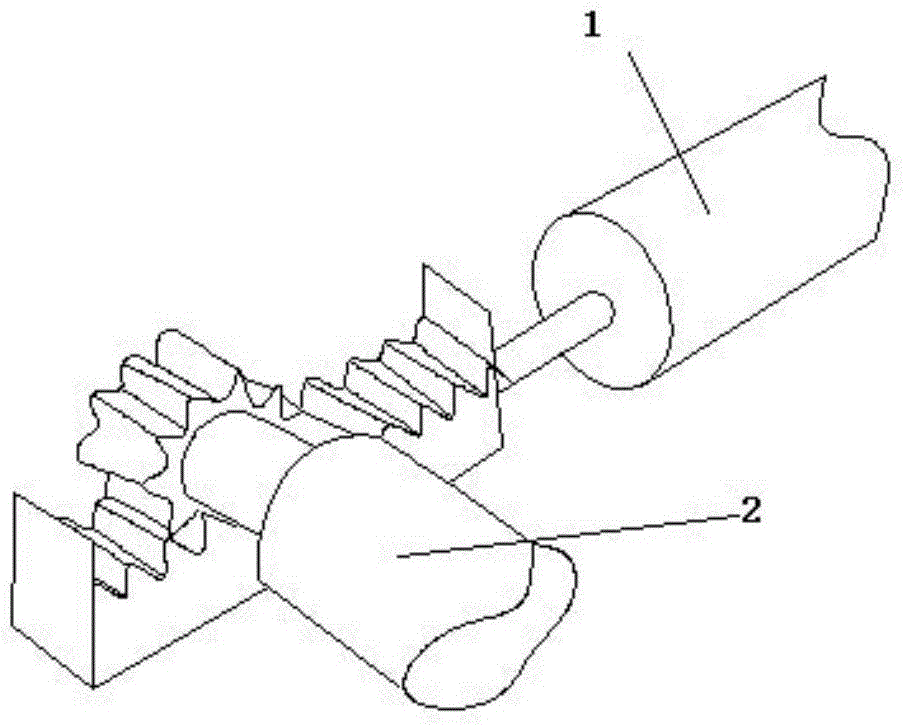

[0013] The reference signs in the description of the drawings are: cylinder 1, transmission shaft 2, rotating arm 3, "L" shaped tray 4, conveyor belt 5, material retaining plate 6, guardrail 7, driving rod 8, suction pipe 9, frame 10, Extension spring 11.

[0014] Such as figure 1 , image 3 As shown, the technical solution provides a lifting device for article transposition, including a frame 10, a lifting device and a transmission device, the lifting device is installed on the frame 10, and the lifting device includes a cylinder 1, a transmission Shaft 2, swivel arm 3 and "L" shaped tray 4. The transmission shaft 2 is hinged on the frame 10, and one end of the transmission shaft 2 is sheathed with a gear, and the tooth plate on the piston rod of the cylinder 1 meshes with the transmission shaft 2 gear, and the cylinder 1 and the transmission shaft 2 are engaged in 90° meshing transmission. The other end of the transmission shaft 2 is fixedly connected to the rotating arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com