Cladding Fiber Bragg Grating Vibration Sensor

A fiber grating and sensor technology, applied in the field of sensors, can solve the problem of not realizing accurate identification of vibration direction and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

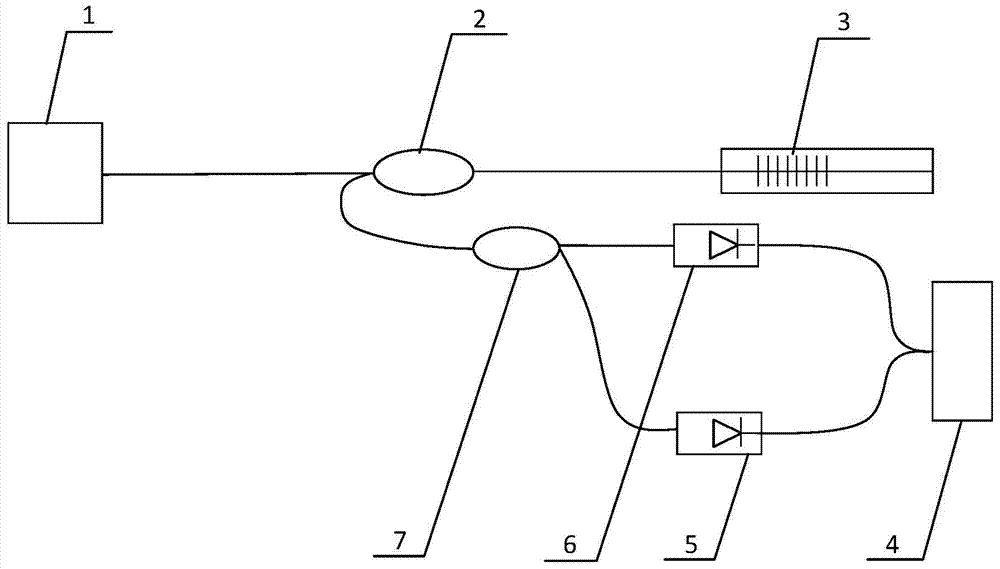

[0018] exist figure 1 Among them, the cladding fiber grating vibration sensor of the present embodiment consists of a semiconductor laser 1, a fiber circulator 2, a fiber grating sensor 3, an oscilloscope 4, a fiber core grating photodetector 5, a cladding grating photodetector 6, a fiber optic wave The multiplexer 7 is connected to form.

[0019] The semiconductor laser 1 is connected to the fiber circulator 2 through a single-mode fiber, and the laser light with a wavelength of 1520-1620nm generated by the semiconductor laser 1 is output to the fiber circulator 2 through the single-mode fiber, and the fiber circulator 2 is connected to the fiber grating sensor 3 and The optical fiber wavelength division multiplexer 7 is connected, the semiconductor laser 1 provides laser light for the fiber grating sensor 3 and the optical fiber wavelength division multiplexer 7, and the optical fiber wavelength division multiplexer 7 passes the single-mode optical fiber and the fiber core g...

Embodiment 2

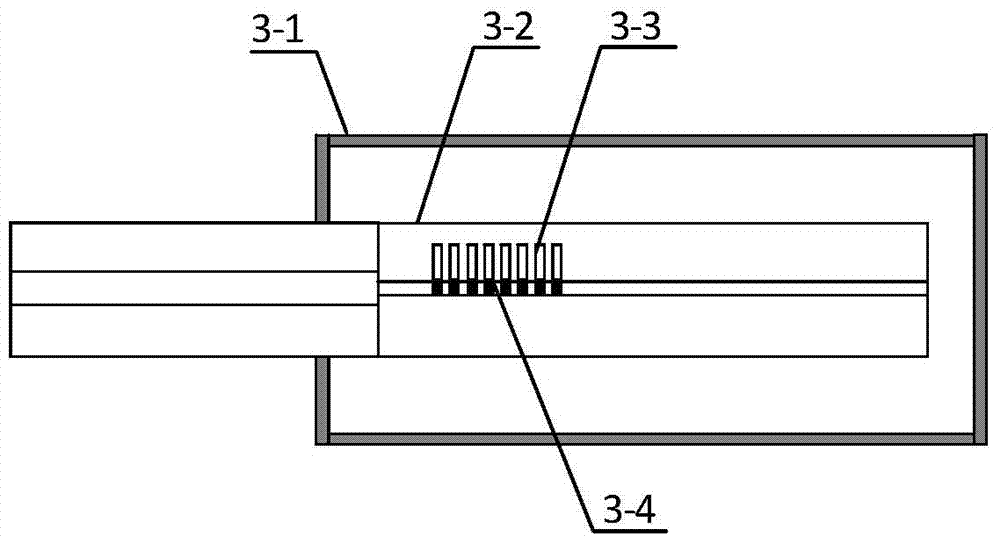

[0022] In this embodiment, the end of the single-mode optical fiber is fused with a thin-core optical fiber 3-2, a core grating 3-4 is written on the core of the thin-core optical fiber 3-2, and a cladding grating 3-4 is written on the fiber cladding. 3. The wavelength of the core grating 3-4 is 1520nm, the wavelength of the cladding grating 3-3 is 1512nm, the length of the cladding grating 3-3 is equal to the length of the fiber core grating 3-4, and the cladding grating 3-3 and The fiber core gratings 3-4 are arranged in parallel at the same axial length position. Other components and the coupling relationship of the components are the same as in Embodiment 1.

Embodiment 3

[0024] In this embodiment, the end of the single-mode optical fiber is fused with a thin-core optical fiber 3-2, the core of the thin-core optical fiber 3-2 is engraved with a core grating 3-4, and the fiber cladding is engraved with a cladding grating 3 -3, the cladding grating 3-3 is engraved on the fiber cladding, the wavelength of the core grating 3-4 is 1620nm, the wavelength of the cladding grating 3-3 is 1612nm, the length of the cladding grating 3-3 is the same as that of the core grating 3-4 are equal in length, and the cladding grating 3-3 and the fiber core grating 3-4 are arranged in parallel at the same axial length position. Other components and the coupling relationship of the components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com