Gasket elasticity test fixture

A technology for elastic testing and gaskets, which is applied in the direction of elastic testing, measuring devices, and mechanical devices, etc., to achieve the effects of quick and convenient testing, improved testing accuracy, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

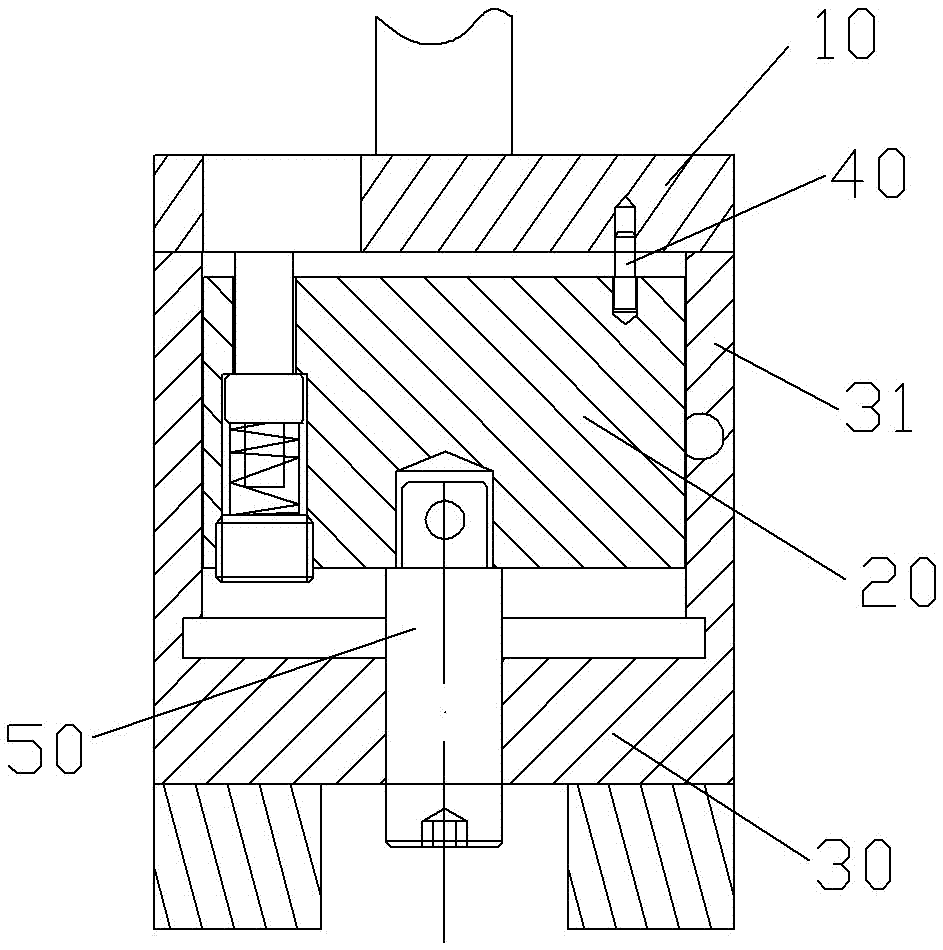

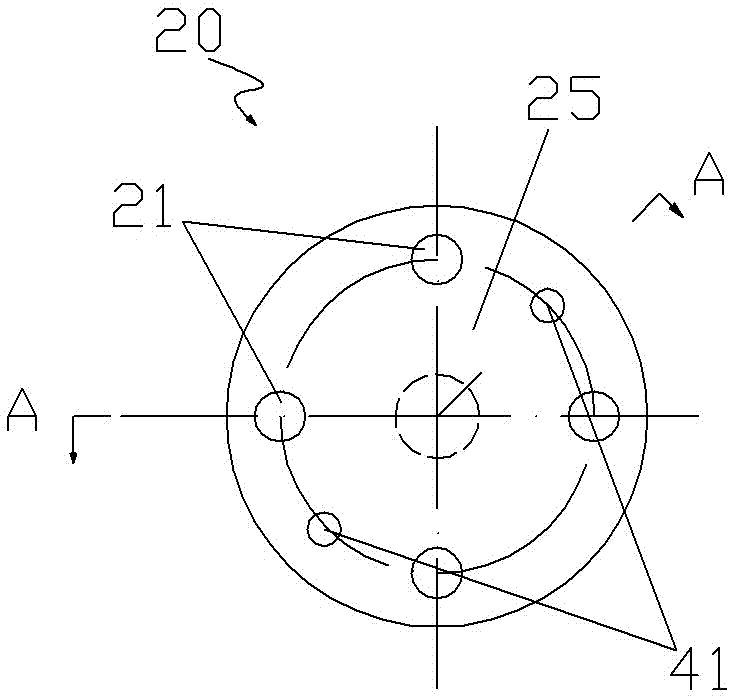

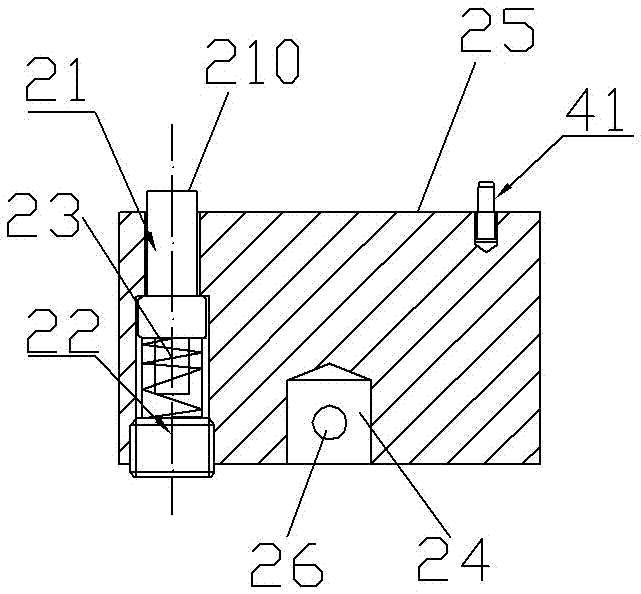

[0034] Such as Figure 1 to Figure 9As shown, an embodiment of a washer elasticity test fixture, the elasticity test fixture in this embodiment is a tooth lock washer elasticity test fixture for performing an elasticity test on a tooth lock washer, and the elasticity test fixture includes vertical The upper clamping block 10 and the lower clamping block 20 distributed in the vertical direction for clamping and compressing the gasket to be tested, the lower clamping block 20 is set on the support base 30 through the support adjustment mechanism 50 along the vertical direction with adjustable height , the support base 30 is provided with a support connecting foot 34, and the support adjustment mechanism 50 has a driving part connected with the lower clamping block to drive the lower clamping block to move in the vertical direction. In this embodiment, the support adjustment mechanism 50 is a continuous adjustment mechanism that can drive the lower clamping block to perform conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com