Method for measuring brittleness of tobacco slice prepared by paper making method

A technology of tobacco sheet and measurement method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problem of unmanned use, and achieve the effect of expanding the scope of research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

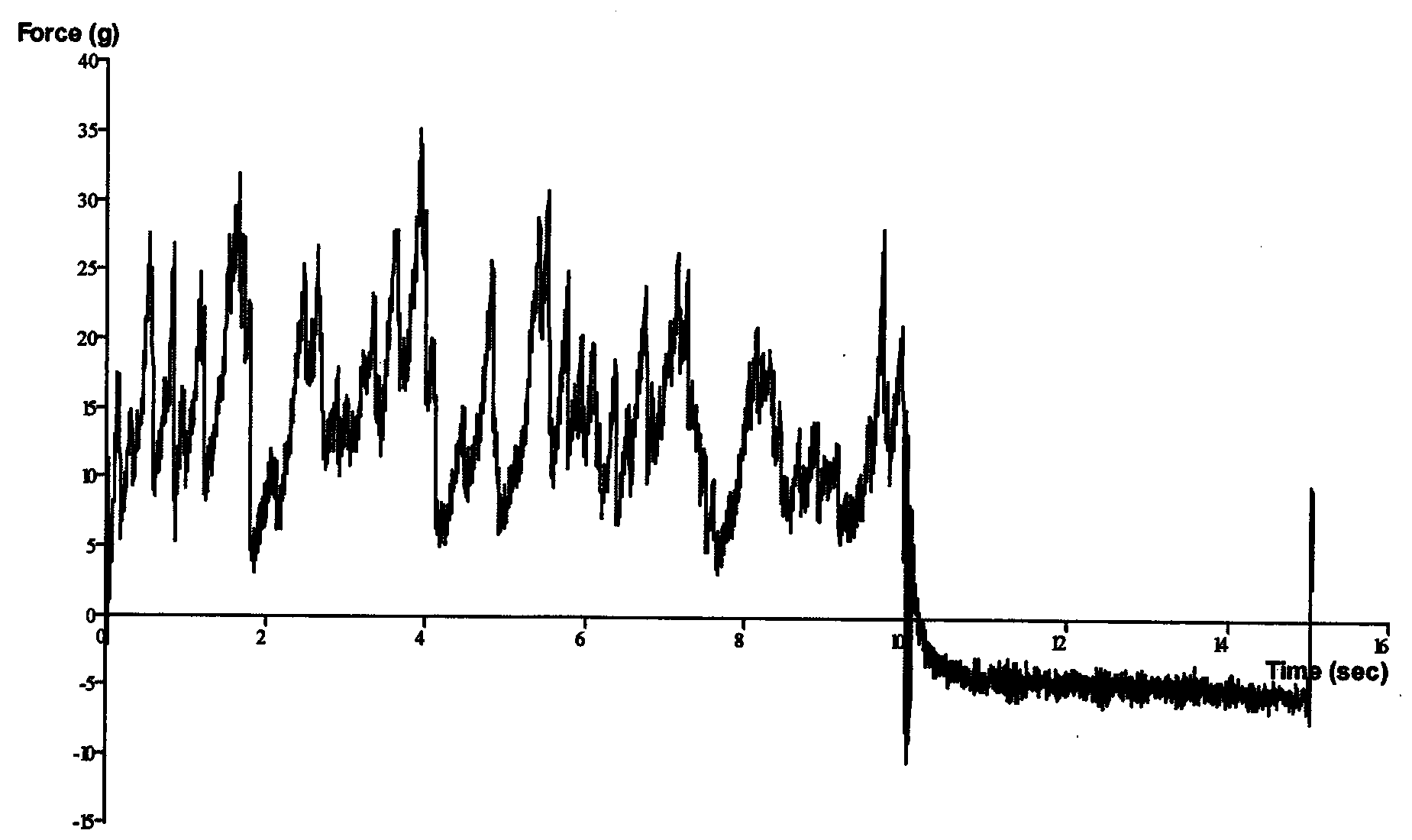

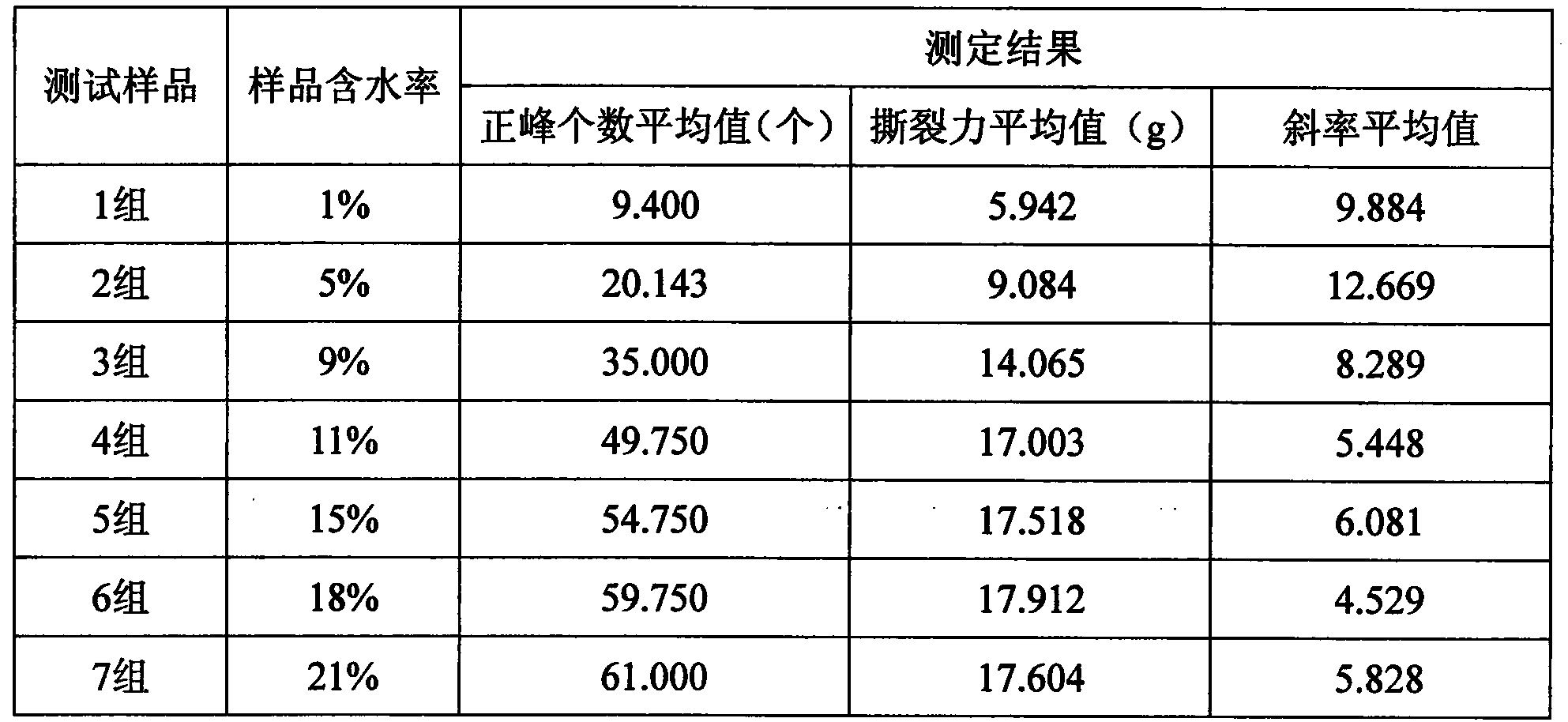

[0024] Using the TA.XT plus texture analyzer produced by British Stable Micro Systems, combined with the A / TG probe of the Tensile Grips series, the brittleness of the same batch of tobacco sheet samples with different moisture contents produced by a domestic thin sheet factory was measured. The specific implementation steps are as follows:

[0025] ① Selection of tobacco sheet samples

[0026] Tobacco sheet samples were unbroken, unwrinkled, uncut tobacco sheets taken from the sheet factory.

[0027] ②Temperature and humidity treatment of tobacco sheet samples

[0028] Condition and test the tobacco sheet according to the environmental conditions of temperature 22°C±2′C and relative humidity 60%±5% specified in GB / T 16447.

[0029] ③ Homogenization treatment

[0030] The homogenization treatment method is firstly to slowly freeze the tobacco sheet in an environment of -7°C to 0°C for 24 hours, and then quickly thaw it in an environment of 60°C to 70°C to room temperature. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com